Walterk

Enlightened

I've been playing with leds for a few years now, and my favorite lights always have been the zoomies:

But the ones from the shops don't go that large.

I built some bigger aspheric zoomies earlier; the Huygens Ultimate, a 250mm (XR-E) 2,1 mcd led lamp, and a 75mm (SST90) with 80kcd.

Usually I get inspired by build-logs or because I want to test how ideas can be combined and applied. Actually I don't 'need' more then one flashlight.

As you know I like postings to be illustrated, so the pictures are again here on Flickr.

This time I was aiming for a simple, compact and solid light.

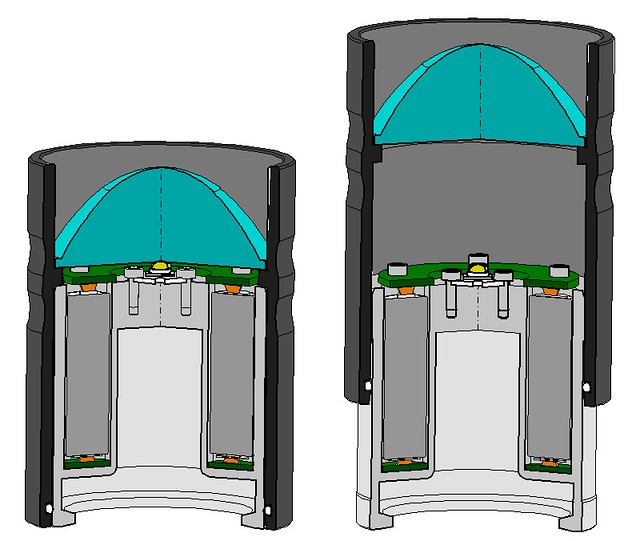

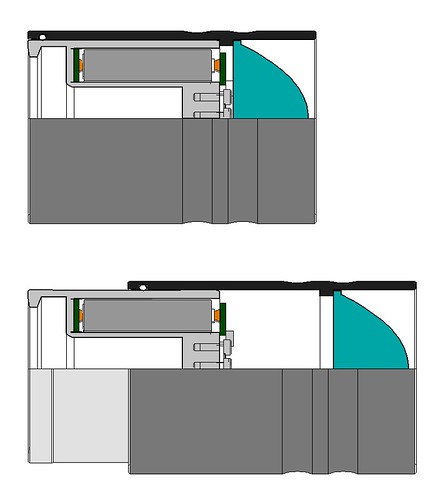

Months ago I decided to go with this concept:

Principle

Moving the lens forward/batteryholder backwards, the led turns on, projecting from flood to focussed. The O-ring is to give friction, holding the position without accidentally losing the head.

When the light is stored, the O-ring should seal the inners from moist and dust.

I planned to use 8xAA Nimh and XM-L direct drive, but DrJones pointed me at the AMC7135 combined with protected Li-ion. I adopted his suggestion as he is smarter then me.

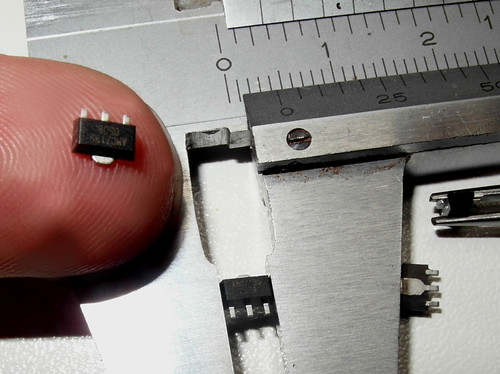

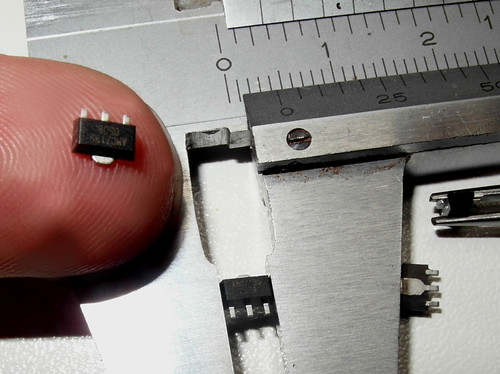

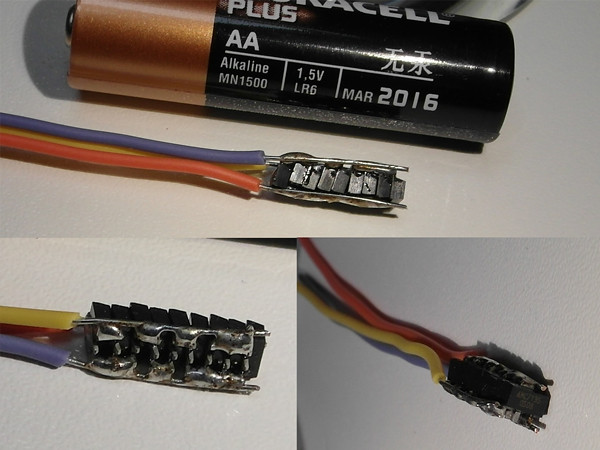

AMC7135 for size:

Soldering the AMC7135 was difficult. Luckily I found someone to help me out with that.

Two out of three of these different lenses will fit. Will choose after testing. And hey, the principle can be adopted to fit any size lens and cells.

One is 78mm DX, other is 75mm Thorlabs (preferred so far) and a 75mm Edmunds. I have another lens (from Ebay) but untill I can find it, it is probably also 78mm.

Will be using a XM-L T5 on copper star, powered at 3.1Amp by 9x AMC7135 from 7x14500 AW Protected cells.

The electronics and reed-switch will be housed in one out of 8 cell-bays.

On the front of the batteryholder a PCB will close the circuit from all batteries to the driver. On this PCB there will be a small spring with a magnet to activate the reed-switch.

That will need some testing and tuning to have it aligned properly.

Still thinking of potting the electronics or not. I like it to be durable, but do want the AMC's to be cool.

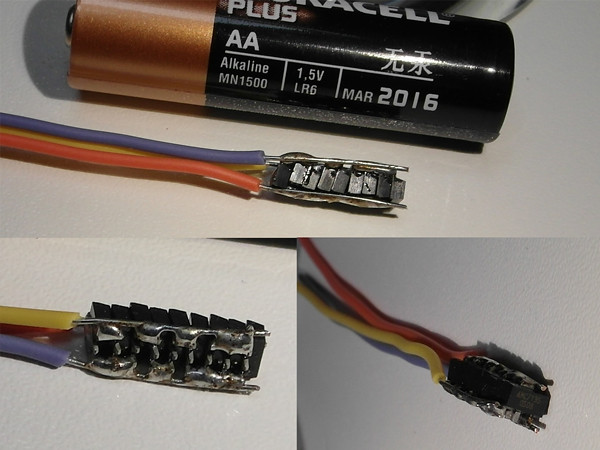

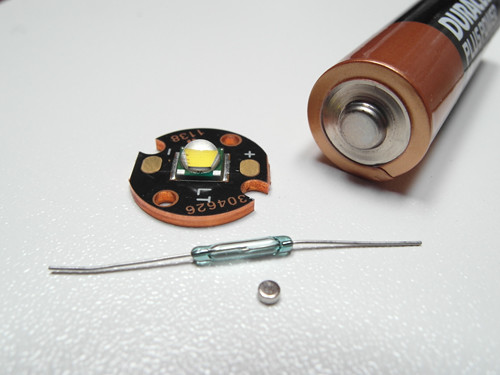

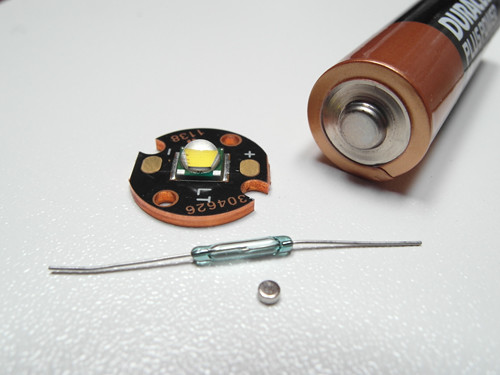

Led and reed and magnet:

The longest wait so far was in finding a workshop that was affordable. Machining is done, very close to perfect, by using a conventional lathe and a CNC-mill.

As it would act like a piston a part of the aluminium has a longitudinal groove for pressure relief. When the light is 'off' , the O-ring seals the innerds.

The light will be anodized black when all testing is done.

Have to make some adjustments to recess some wiring, enlargeing the relief groove and sand/polish the aluminium to fine-tune the pressure from the O-ring.

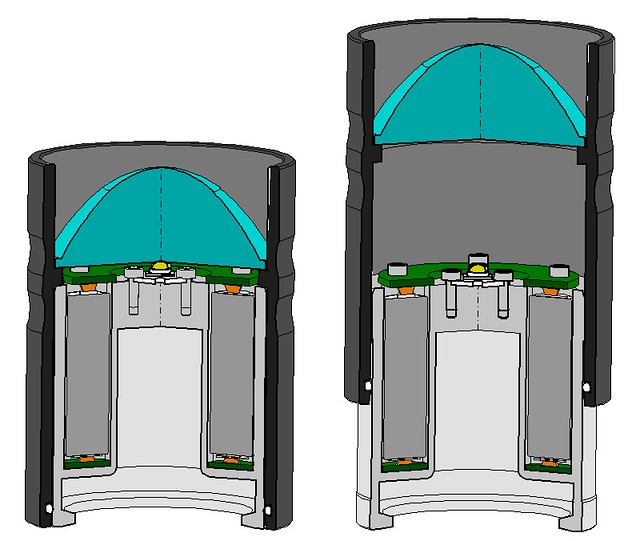

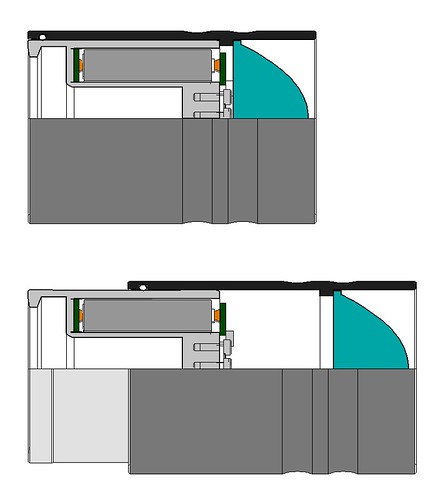

Assembly in off/storage position

Assembly in on/focused position (45mm BFL)

This light is now about 1/3th finished. What do you think? Could it work?

But the ones from the shops don't go that large.

I built some bigger aspheric zoomies earlier; the Huygens Ultimate, a 250mm (XR-E) 2,1 mcd led lamp, and a 75mm (SST90) with 80kcd.

Usually I get inspired by build-logs or because I want to test how ideas can be combined and applied. Actually I don't 'need' more then one flashlight.

As you know I like postings to be illustrated, so the pictures are again here on Flickr.

This time I was aiming for a simple, compact and solid light.

Months ago I decided to go with this concept:

Principle

Moving the lens forward/batteryholder backwards, the led turns on, projecting from flood to focussed. The O-ring is to give friction, holding the position without accidentally losing the head.

When the light is stored, the O-ring should seal the inners from moist and dust.

I planned to use 8xAA Nimh and XM-L direct drive, but DrJones pointed me at the AMC7135 combined with protected Li-ion. I adopted his suggestion as he is smarter then me.

AMC7135 for size:

Soldering the AMC7135 was difficult. Luckily I found someone to help me out with that.

Two out of three of these different lenses will fit. Will choose after testing. And hey, the principle can be adopted to fit any size lens and cells.

One is 78mm DX, other is 75mm Thorlabs (preferred so far) and a 75mm Edmunds. I have another lens (from Ebay) but untill I can find it, it is probably also 78mm.

Will be using a XM-L T5 on copper star, powered at 3.1Amp by 9x AMC7135 from 7x14500 AW Protected cells.

The electronics and reed-switch will be housed in one out of 8 cell-bays.

On the front of the batteryholder a PCB will close the circuit from all batteries to the driver. On this PCB there will be a small spring with a magnet to activate the reed-switch.

That will need some testing and tuning to have it aligned properly.

Still thinking of potting the electronics or not. I like it to be durable, but do want the AMC's to be cool.

Led and reed and magnet:

The longest wait so far was in finding a workshop that was affordable. Machining is done, very close to perfect, by using a conventional lathe and a CNC-mill.

As it would act like a piston a part of the aluminium has a longitudinal groove for pressure relief. When the light is 'off' , the O-ring seals the innerds.

The light will be anodized black when all testing is done.

Have to make some adjustments to recess some wiring, enlargeing the relief groove and sand/polish the aluminium to fine-tune the pressure from the O-ring.

Assembly in off/storage position

Assembly in on/focused position (45mm BFL)

This light is now about 1/3th finished. What do you think? Could it work?