recDNA

Flashaholic

- Joined

- Jun 2, 2009

- Messages

- 8,761

Still like my bling shiny.

No such thing as too shiny in my book.

No such thing as too shiny in my book.

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum

With the right equipment & media, tumbling for stone washing isn't done for a long period of time to get the effect. Tumbling for long periods of time is just deburring which is not what you want for stone washing.

Here are the variables that figure into the equation:

Composition of the tumbling media

Density of media

Frangibility of media

Abrasiveness of media

Shape of media

Size & shape of tumbler barrel

RPM of barrel

Time

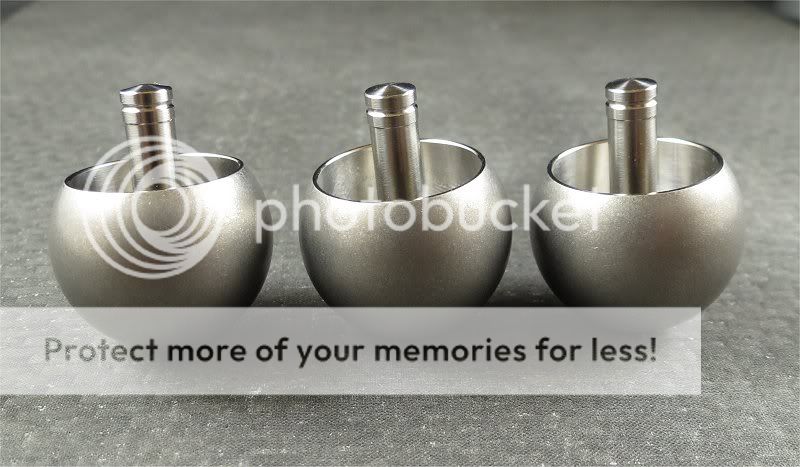

Media that's highly abrasive & highly frangible will deburr parts in a short time. Media that's ultra fine & super hard requires a long run in the tumbler. The images below show a McGizmo SunDrop XRU after stone wash. In my tumbler with the media I use the time required is 72 hours.

Un modded SunDrop on left, stone washed on right:

IMO there is much greater variability in stone washing than in most other surface finishes. Stone wash from Maker A will always look different than stone wash from Maker B. Unless both use the exact same media & identical equipment.

There are certainly some combinations of high energy centrifugal tumblers & coarse abrasives that would destroy a knife blade ... or a flashlight. At the other extreme are low energy machines & ultra fine abrasives that will not even remove shallow etching. After 84 hours the etching is still clear & sharp:Tumbling for 72 hours would not work for knife blades though.

There are certainly some combinations of high energy centrifugal tumblers & coarse abrasives that would destroy a knife blade ... or a flashlight. At the other extreme are low energy machines & ultra fine abrasives that will not even remove shallow etching. After 84 hours the etching is still clear & sharp: