Z

z_J S Machine

Guest

Hello folks. I don't have many posts on this forum. I came here with interest in lights, but I stumbled upon this forum when checking out all of the others. I said hey, I can do that, lol..what a coincidence..Here are some of my pieces.

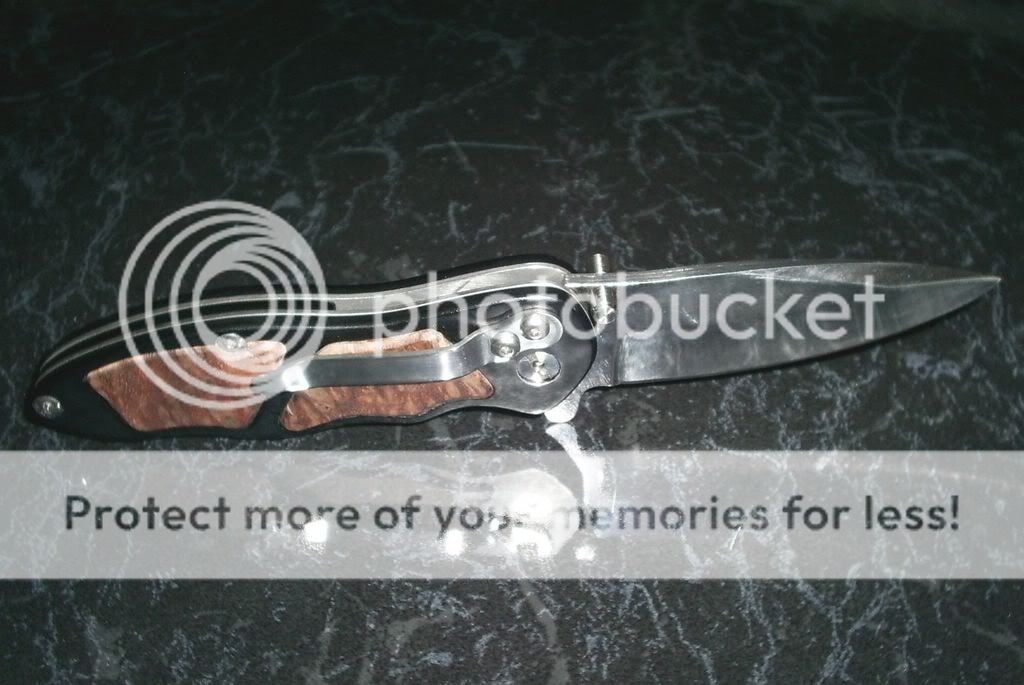

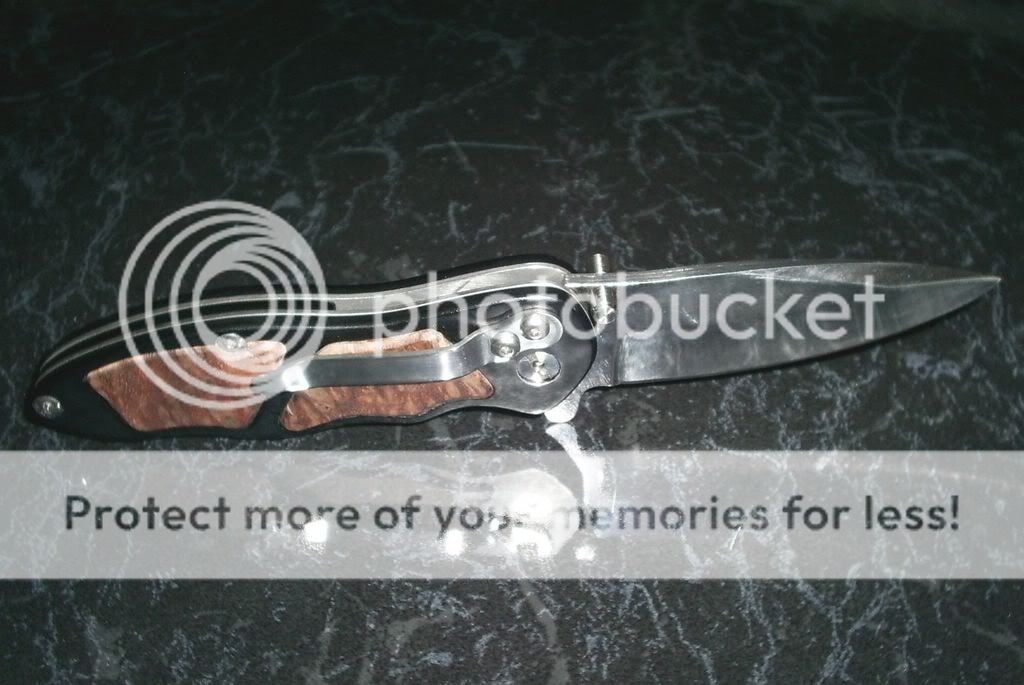

I started out with this one. It has aluminum scales with eucalyptus wood inserts, a cruwear (crucible branded steel) blade that is hollow ground, 410 SS liners and pocket clip, and 300 series SS pivot pin/nut and thumbstuds. The scales are anodized black. The only thing purchased were the screws and the anodizing. This was my first knife, took me about a month to build it in '07, and I carry it every day:

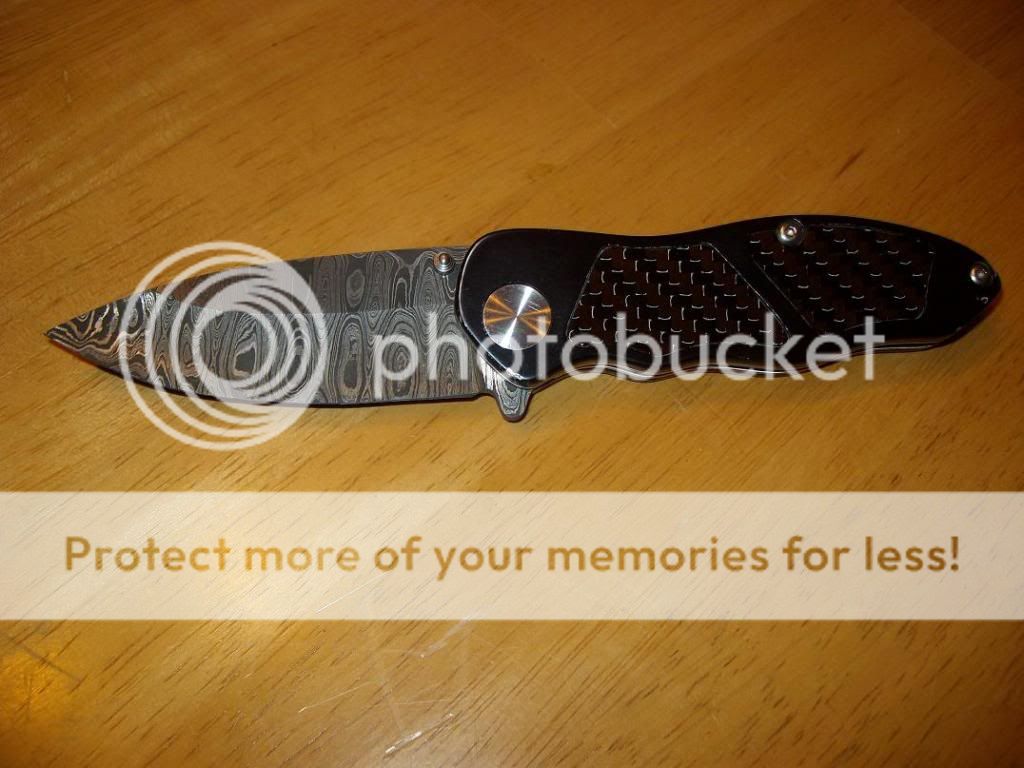

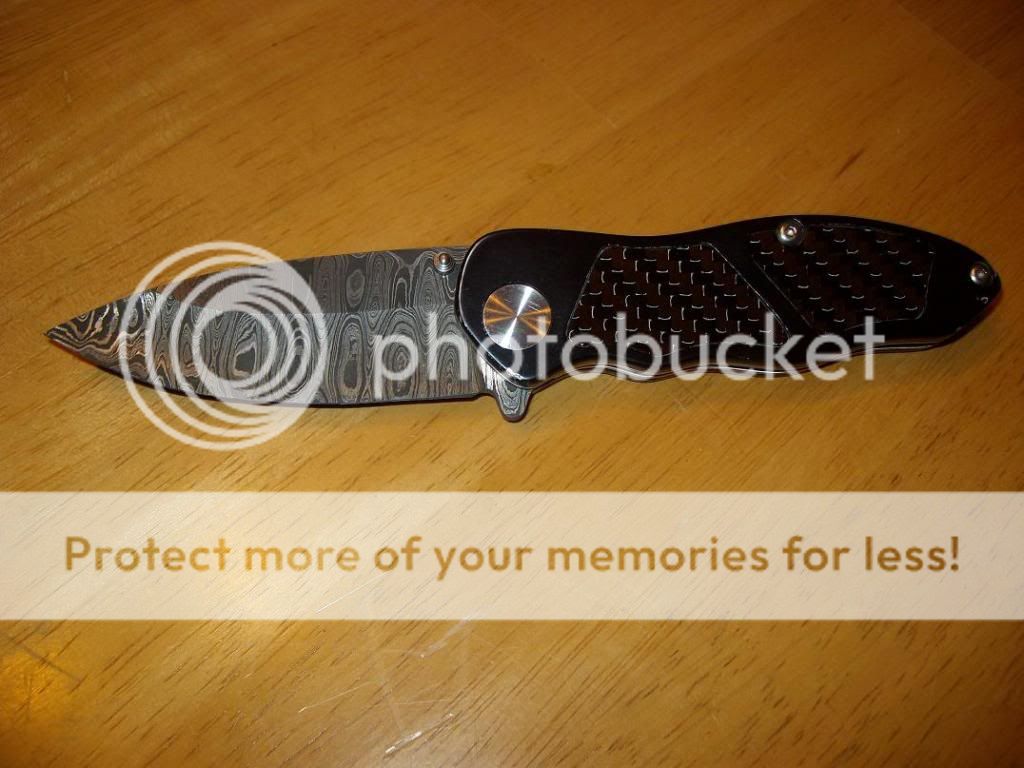

I recently upgraded to a damascus blade (hollow ground as well) and carbon fiber handle inserts:

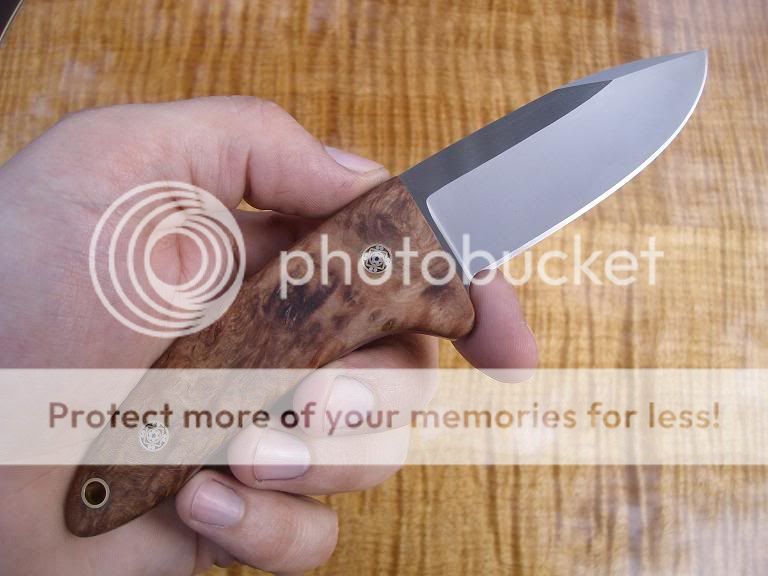

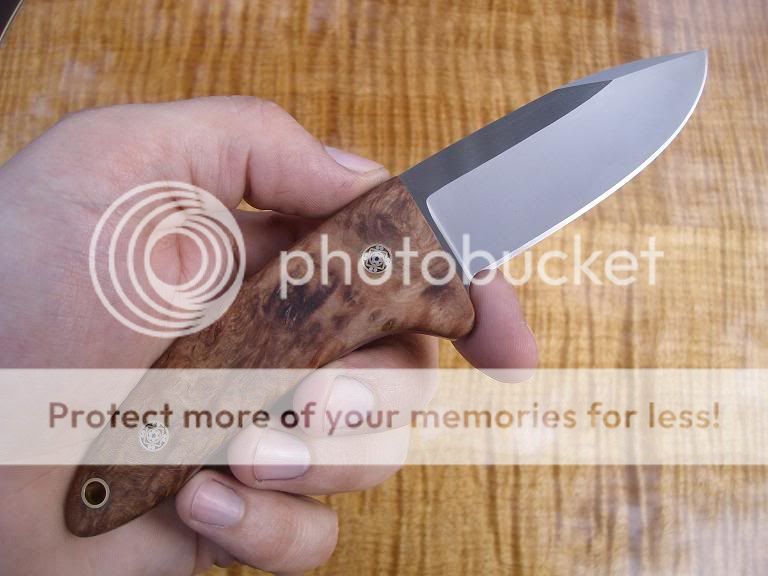

This was my first fixed blade, and second knife overall. It has a D2 hollow ground blade with the same eucalyptus wood used in the first knife above for scales, mosaic pins and file work in the spine.

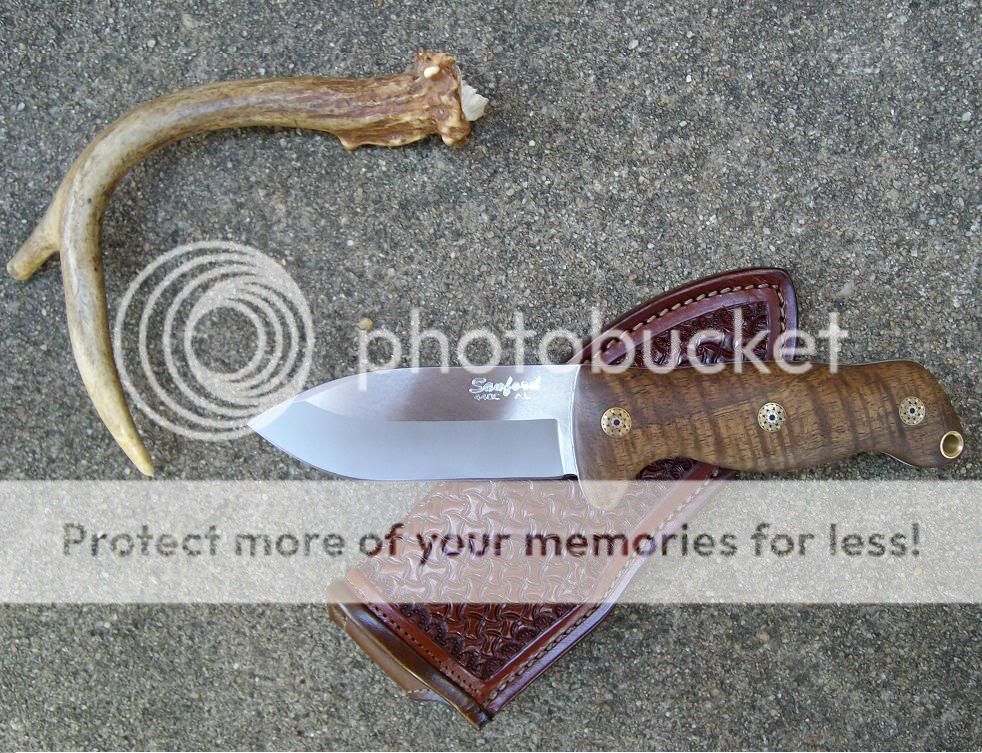

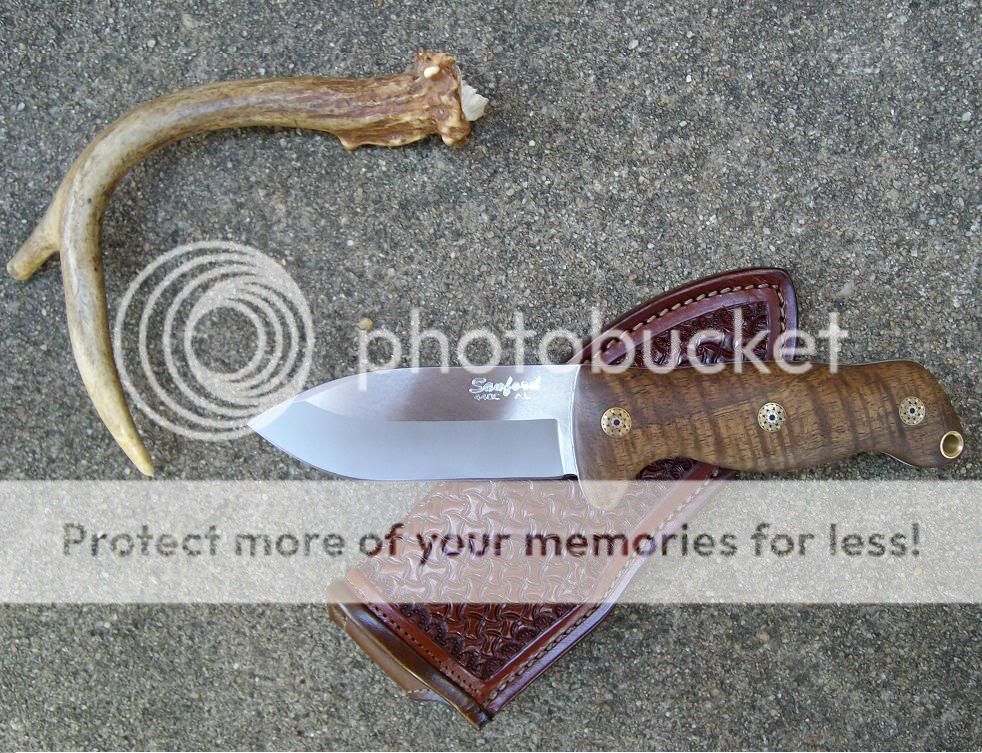

I made this next knife and donated it for St. Jude Children's hospital to be auctioned off. A custom sheath maker in Texas made the sheath - his name is Paul Long. This knife has Hawaiian koa handle scales, mosaic pins, fiber spacers, filework in the spine, and it is made of 440C SS and hollow ground. It sold for $500 at the auction. I was blown away..

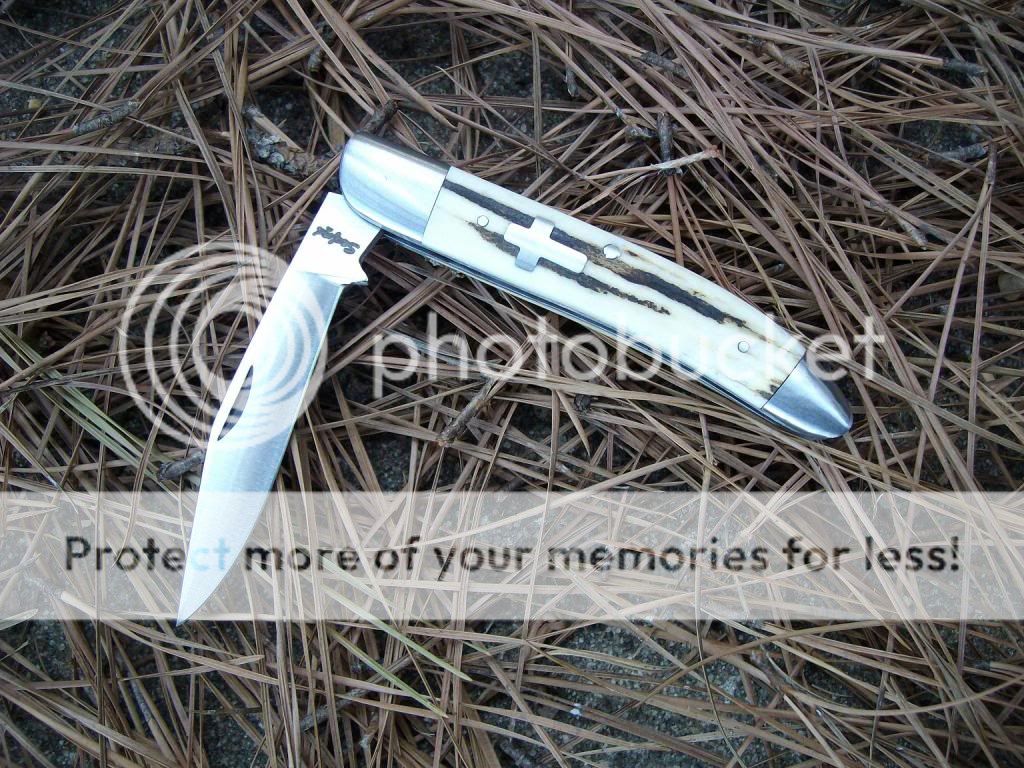

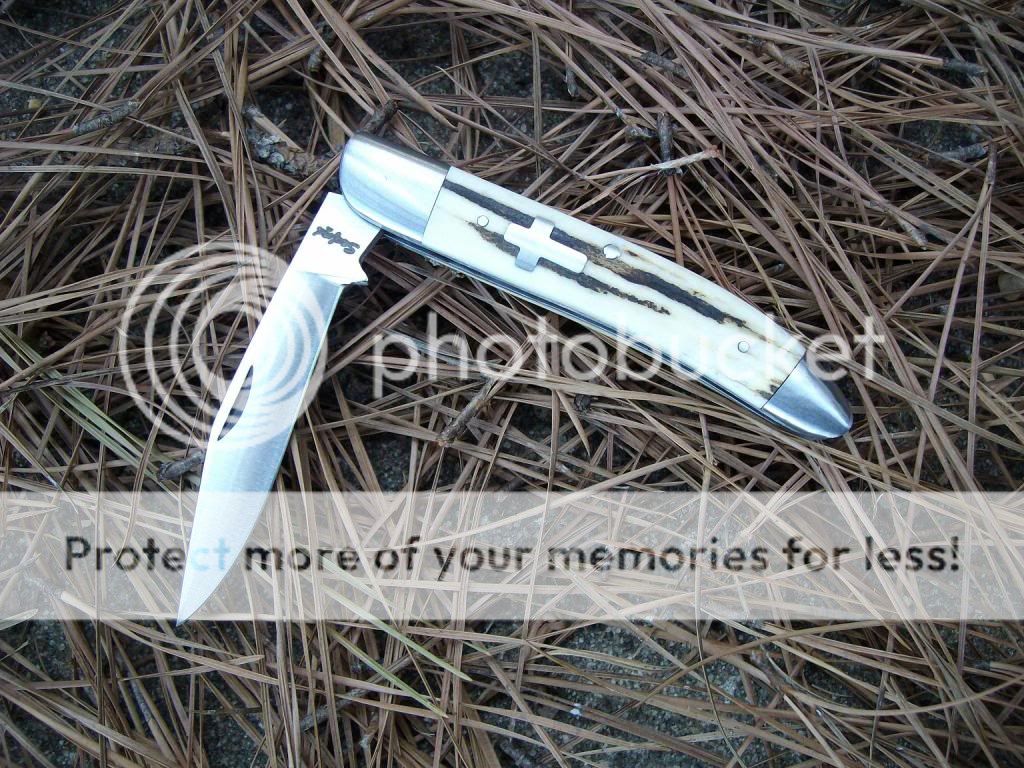

And then I attempted my first slipjoint..Which was a real pain in the rear but I did pull it off. German AEB-L steel for the blade - flat ground, sambar stag handle scales, 410 SS bolsters, liners, pins and shield.

That's all I have so far. I don't work very fast or have much time to dedicate to it, but I do it every now and then. I am a machinist, toolmaker for a living so I kind of had a head start into the metal side of things, but every thing else was learned as I have come along. Knife making is not easy, especially if you want to do it right. Bottom line.

Hope you enjoyed the pics.

I started out with this one. It has aluminum scales with eucalyptus wood inserts, a cruwear (crucible branded steel) blade that is hollow ground, 410 SS liners and pocket clip, and 300 series SS pivot pin/nut and thumbstuds. The scales are anodized black. The only thing purchased were the screws and the anodizing. This was my first knife, took me about a month to build it in '07, and I carry it every day:

I recently upgraded to a damascus blade (hollow ground as well) and carbon fiber handle inserts:

This was my first fixed blade, and second knife overall. It has a D2 hollow ground blade with the same eucalyptus wood used in the first knife above for scales, mosaic pins and file work in the spine.

I made this next knife and donated it for St. Jude Children's hospital to be auctioned off. A custom sheath maker in Texas made the sheath - his name is Paul Long. This knife has Hawaiian koa handle scales, mosaic pins, fiber spacers, filework in the spine, and it is made of 440C SS and hollow ground. It sold for $500 at the auction. I was blown away..

And then I attempted my first slipjoint..Which was a real pain in the rear but I did pull it off. German AEB-L steel for the blade - flat ground, sambar stag handle scales, 410 SS bolsters, liners, pins and shield.

That's all I have so far. I don't work very fast or have much time to dedicate to it, but I do it every now and then. I am a machinist, toolmaker for a living so I kind of had a head start into the metal side of things, but every thing else was learned as I have come along. Knife making is not easy, especially if you want to do it right. Bottom line.

Hope you enjoyed the pics.