Osprey_Guy

Enlightened

To begin with...I did a similar post in the Raw Da thread in the "Manufacturers Corner", but it occured to me that most of you would miss it there. So I'm more or less duplicating my post here.

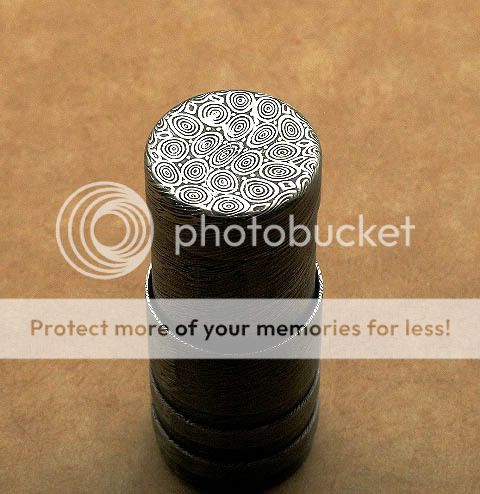

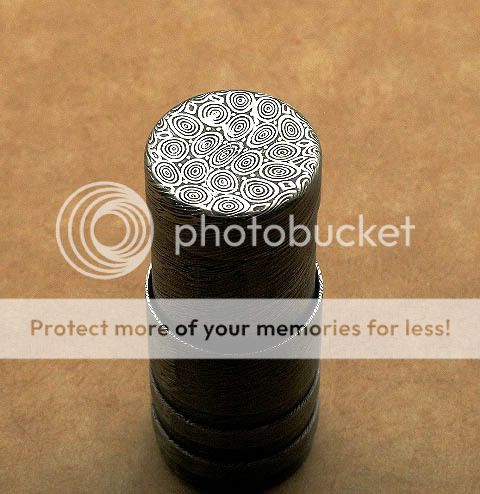

I just finished work on another one of the "Raw" series of custom-made, mini-flashlights by Rob Cheetham from "Orb". Identical in size to the anodized Titanium version I showed in another thread, this "Damasteel" version also shares the same technical specs (aka "It's screaming bright!"). :rock:

Rob never worked with damascus before...he basically gave himself a crash course in etching. He did a fine job with the etch, and as expected the Raw Da turned out to be a very coo-looking light. But without any real post-etch work, the final finish was rather dull-looking. In his defense, Rob's (considerable) expertise is with the lights, not with the steel. That's where I come in...

The customer, one of the first to receive the lights, had contacted me and asked if I could do anything with the finish (he originally wanted to know if I could "color it" in the same way I've done a number of Mr Bulk's carbon damascus "Dam Chams"... I explained that the Raw Da's were made of "Damasteel", a type of stainless damascus...and that stainless steel can't be nitre blued. But based on the photos I'd seen, I told him that I was certain that I could improve on the finish.

Using very fine sandpaper, polishing papers, buffing/polishing "burs" attached to my brand new Foredom Micromotor handpiece (it's very cool...I love it!), and a final touch with Ren wax, by the time I got finished with it, the difference was dramatic.

My photography skills are limited and whenever I post flashlight pics I usually find myself making all sorts of excuses for the photos. I can show the basic "gist" of the lights, but I've never been able to figure out how to show off the sort of "shine, gleam, shimmer, gloss" surfaces that I can achieve on the re-finished lights. And that's the case with these pics as well. So you'll just have to take my word for it...the light is highly polished.

Anyway, here goes...

This was the toughest shot...I just can't figure out how to show how VERY shiny the base is now. The difference between the way the light looked when I received it, compared with the way it looks now, is positively HUGE!!! Overall the Raw Da is now gleaming. And the good-looking raindrop pattern on the base is truly shimmering, with its near mirror finish (It looks so different in the photo...you'd never guess that it was highly polsihed...oh well).

It ships back to the customer in Germany tomorrow. I think he's gonna be pleased.

Dennis Greenbaum

I just finished work on another one of the "Raw" series of custom-made, mini-flashlights by Rob Cheetham from "Orb". Identical in size to the anodized Titanium version I showed in another thread, this "Damasteel" version also shares the same technical specs (aka "It's screaming bright!"). :rock:

Rob never worked with damascus before...he basically gave himself a crash course in etching. He did a fine job with the etch, and as expected the Raw Da turned out to be a very coo-looking light. But without any real post-etch work, the final finish was rather dull-looking. In his defense, Rob's (considerable) expertise is with the lights, not with the steel. That's where I come in...

The customer, one of the first to receive the lights, had contacted me and asked if I could do anything with the finish (he originally wanted to know if I could "color it" in the same way I've done a number of Mr Bulk's carbon damascus "Dam Chams"... I explained that the Raw Da's were made of "Damasteel", a type of stainless damascus...and that stainless steel can't be nitre blued. But based on the photos I'd seen, I told him that I was certain that I could improve on the finish.

Using very fine sandpaper, polishing papers, buffing/polishing "burs" attached to my brand new Foredom Micromotor handpiece (it's very cool...I love it!), and a final touch with Ren wax, by the time I got finished with it, the difference was dramatic.

My photography skills are limited and whenever I post flashlight pics I usually find myself making all sorts of excuses for the photos. I can show the basic "gist" of the lights, but I've never been able to figure out how to show off the sort of "shine, gleam, shimmer, gloss" surfaces that I can achieve on the re-finished lights. And that's the case with these pics as well. So you'll just have to take my word for it...the light is highly polished.

Anyway, here goes...

This was the toughest shot...I just can't figure out how to show how VERY shiny the base is now. The difference between the way the light looked when I received it, compared with the way it looks now, is positively HUGE!!! Overall the Raw Da is now gleaming. And the good-looking raindrop pattern on the base is truly shimmering, with its near mirror finish (It looks so different in the photo...you'd never guess that it was highly polsihed...oh well).

It ships back to the customer in Germany tomorrow. I think he's gonna be pleased.

Dennis Greenbaum

Last edited: