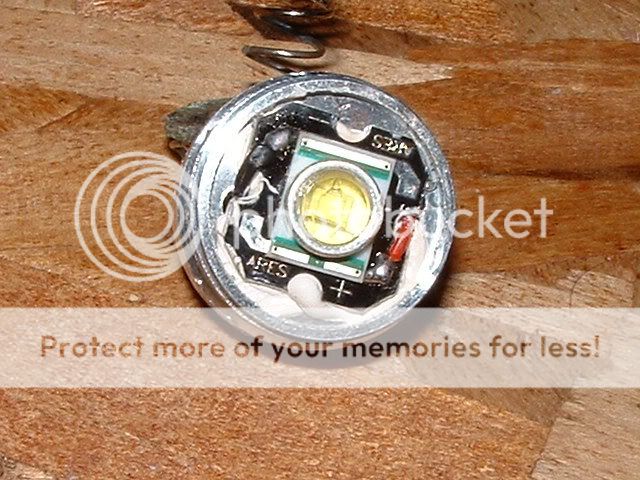

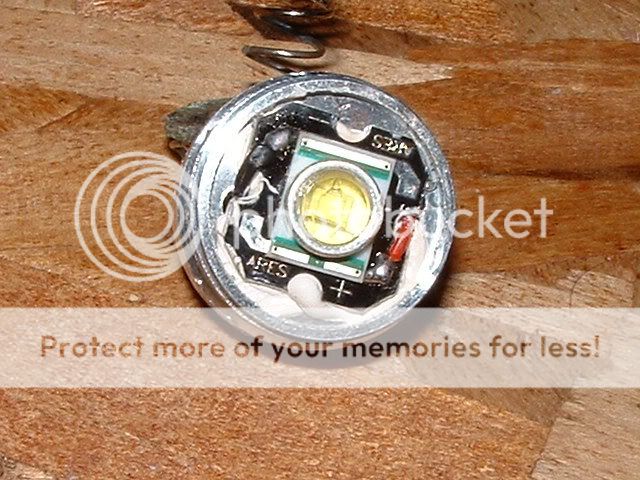

Looks like a P4. It's kind of hard to see in your photo, but it looks like your CREE is the newer type which has 4 bond wires. The newer CREE's with 4 bond wires should all be at least P4 bin or better as far as I know.

Grounding (or wiring shorts) are typically what screw up these lights, so if your light arrived dead, then I would check for these problems.

The resistor looks like Green/Black/Silver/Gold which is only a 0.5 ohm, so you are probably driving the emitter at about the right level already.

Calling a simple resistor a 'regulated' driver is indeed pretty sleazy (though technically the resistor does 'regulate' the current flow, just not in the sense of holding constant current drive).

I wouldn't mess with 'direct-drive'. Calling the Resistor a regulator is a joke, but Direct-Drive is a STUPID JOKE, dreamed up by know-nothing 'experts' who have no clue about how LED emitters need to be driven.

To get TRUE constant current drive (and safely drive the P4 at high current levels), DX has several 7135 based regulated boards that would work well.

DX has 7135 boards that run single output modes at 350ma, 700ma, 1050ma, and 1400ma.

The circuit is actually quite simple. Each 7135 chip gives 350ma of constant-current regulated drive to the LED emitter, and the higher output boards just have 2, 3, or 4 of these 7135 chips in parallel. If you get the 1400ma board it has 4 chips and you can enable/disable some of the chips to set 350ma, 700ma, 1050ma, or 1400ma. of drive.

DX used to sell these 7135 driver boards in single quantity, but now I can only find 10 and 20 qty packages on thier web site, so you might want to contact them to see if they can quote you a price for just 1 of the 1400ma driver boards.

http://www.dealextreme.com/details.dx/sku.1886

They do have a nice multi-mode 7135 board in single quantity. This board has multiple modes and drive levels with low/med/high/stobe/SOS settings with the high level at 1000ma (a high drive level for a P4, but should work well with good heatsinking).

http://www.dealextreme.com/details.dx/sku.6190

These 7135 boards can give TRUE regulated performance, with a nice consistant output level which will not change much in brightness as your battery starts to discharge.

To work well, these 7135 boards need to have a good solid mechanical connection around the perimeter of the circuit board to the flashlight body, which gives both electrical grounding and thermal heatsinking for the regulator chips.

You can search CPF and find quite a bit of info about these boards if you need more info.