csshih

Flashlight Enthusiast

We all have our oops moments.

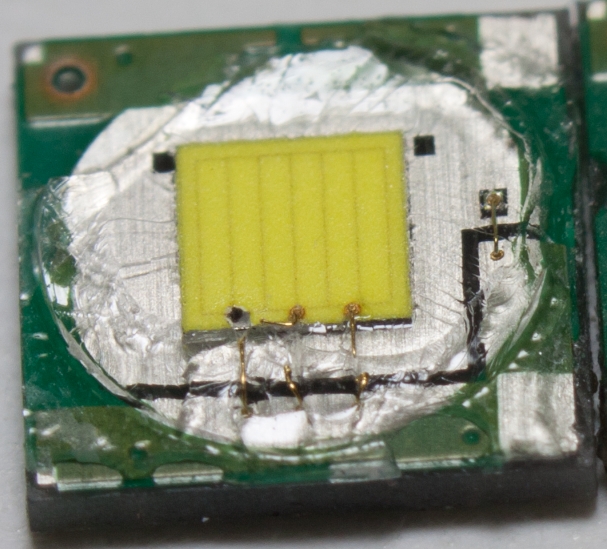

I just happen to have 2. Let's just say, those bond wires weren't meant to carry whatever current jumped into them at ~19V.... :scowl:

while de-doming, the bondwires broke, but if you look closely (not too closely), you'll see that the middle of the left one, and left bond wire of the right one are uh, toasted.

I scraped the phosphor off the left one.

over there in the corner is the ESD protection diode. uh, it got scraped off on the left one

let's have a look at the LED, with different lighting:

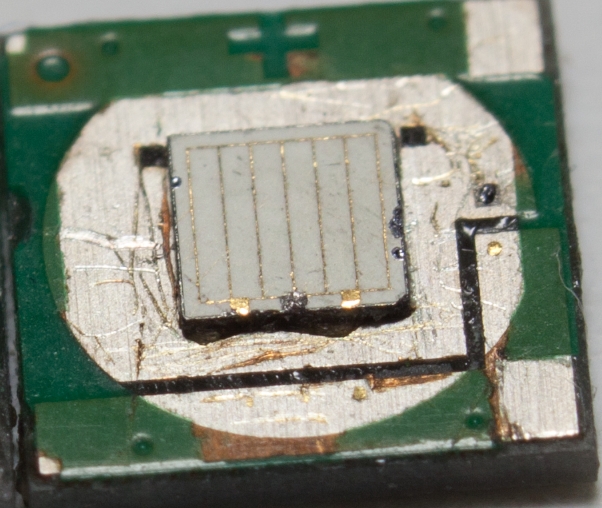

I just happen to have 2. Let's just say, those bond wires weren't meant to carry whatever current jumped into them at ~19V.... :scowl:

while de-doming, the bondwires broke, but if you look closely (not too closely), you'll see that the middle of the left one, and left bond wire of the right one are uh, toasted.

I scraped the phosphor off the left one.

over there in the corner is the ESD protection diode. uh, it got scraped off on the left one

let's have a look at the LED, with different lighting: