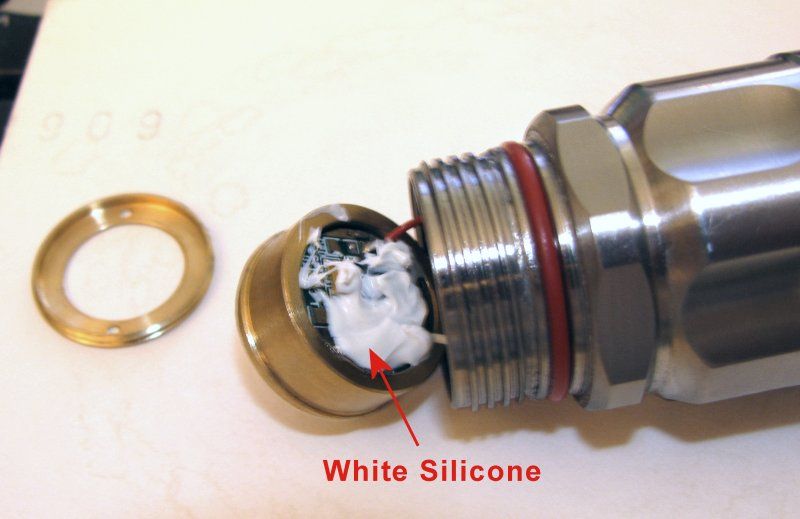

I see that BugOutGearUSA is no longer selling JetBeam (where I bought these models in 2008), and had a minor problem with one when changing batteries last night. The bottom of the LED Driver circuit has a raised metal disc (like a thin 5mm diameter Neodymium magnet) that came off as shown in these two photos. Anyone know if there is a simple do-it-myself fix for this, or if JetBeam has a service available in the USA to fix it? Thanks guys.