Power Me Up

Enlightened

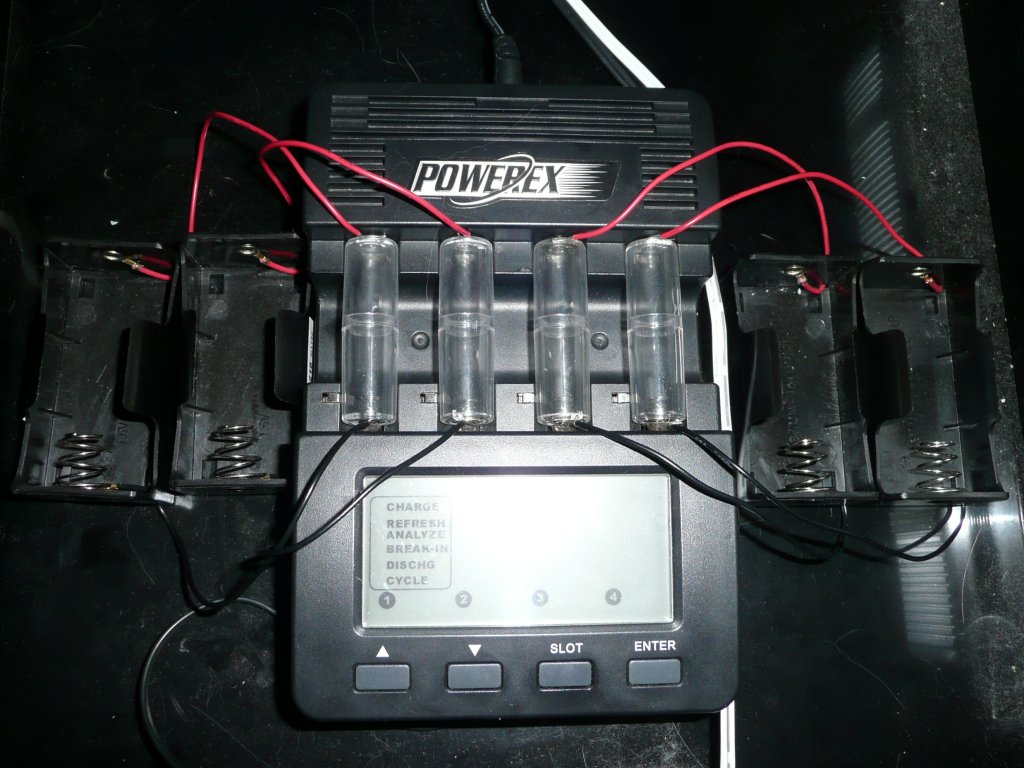

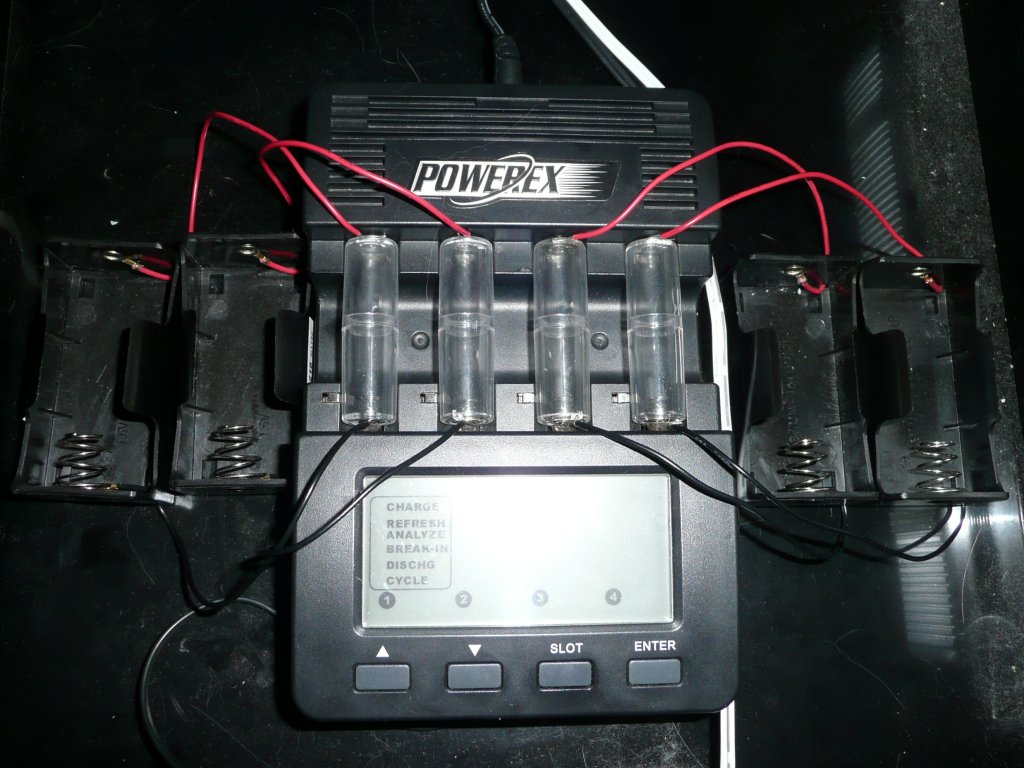

Since there seems to be some confusion on how to connect C and D sized cells to a Maha C9000, I'll create this thread and include a photo of how I've done it:

Keep in mind that I'm using one of the earlier generation C9000 chargers that measures the cell voltage during the rest period instead of whilst the cell is under load - this pretty much eliminates the effect of the lead resistance.

The clear AA sized adapters that hold the leads in place came from DealExtreme:

http://www.dealextreme.com/details.dx/sku.3657

The C & D sized individual holders came from a local electronics store.

Feel free to post any questions!

Keep in mind that I'm using one of the earlier generation C9000 chargers that measures the cell voltage during the rest period instead of whilst the cell is under load - this pretty much eliminates the effect of the lead resistance.

The clear AA sized adapters that hold the leads in place came from DealExtreme:

http://www.dealextreme.com/details.dx/sku.3657

The C & D sized individual holders came from a local electronics store.

Feel free to post any questions!