Hello!

Quite some time ago i sparked the idea to build a flashlight, it is a few months later now and i have a rough idea on how to do it.

In my parts bin are about ten 18650 cells, 20 LED drivers, a few Nichia LEDs and a 3D printer, all that needs to be put to good use.

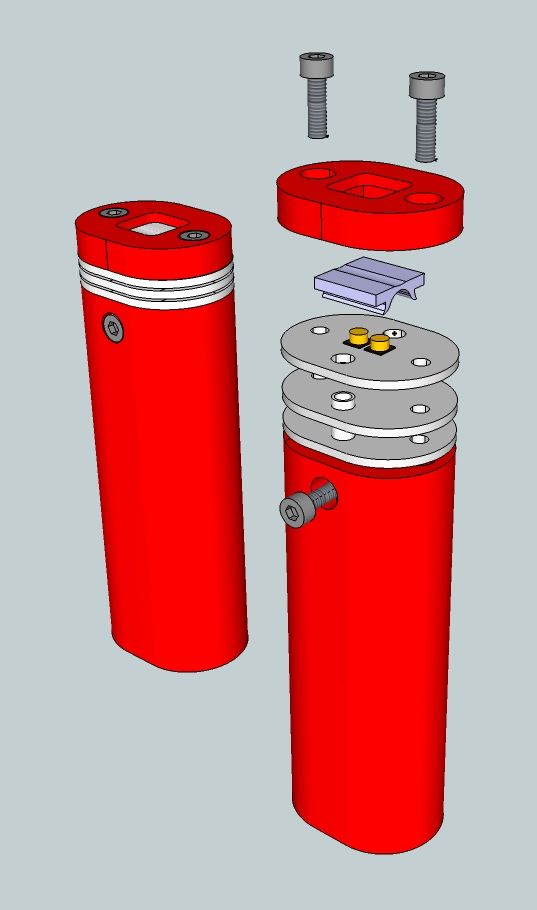

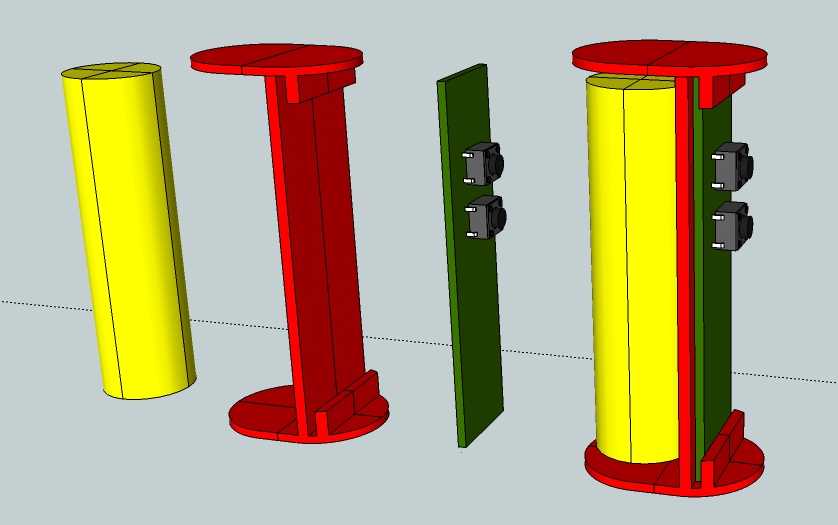

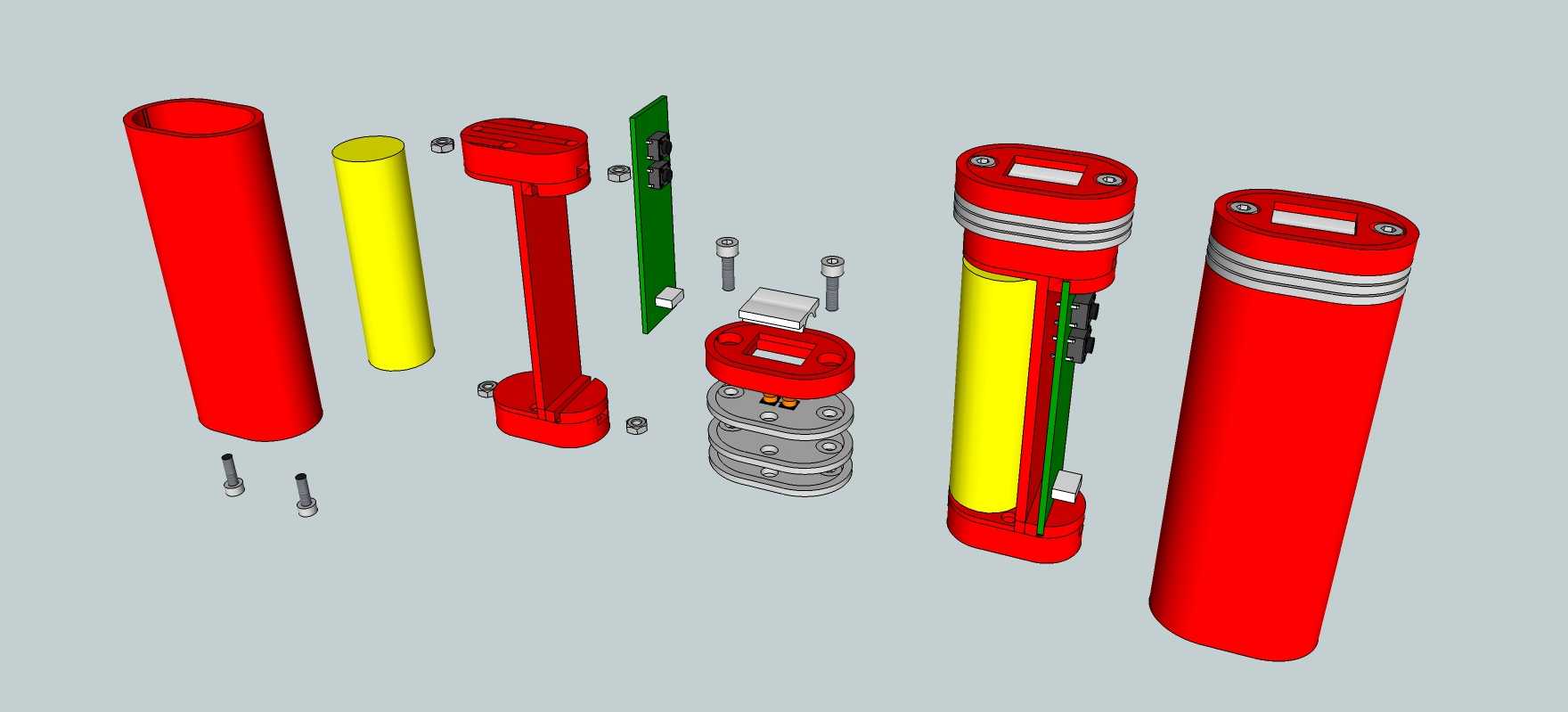

So i am set on these four things, here is what i came up with so far, just made some prints to have something in my hand to play with:

http://imgur.com/qankruB

What i know so far, a 3D printed case seems to be viable (if printed in PETG), heat dissipation of the LED will be a problem, 18650 makes the light a bit too big then i would like to but i do not want to buy new batteries.

LED options:

Nichia NF2L385AR,170 Lumen, 2700K with 83RA

Nichia NF2W385AR,197 Lumen, 5000K with 83RA

Cree MK-R, 350 Lumen, 2700K with 80RA

I am unsure about a lens, either a whide angle or none at all, i want a floodlight.

If possible i want to put a temp sensor in there so the light can regulate the power down if it gets too hot, just a cheap NTC/Resistor solution.

LED Driver with no PWM

Texas Instruments TPS61165,i have 20 of them and they fit the LED nicely.

It has a digital interface and can regulate the current in 31 steps.

With a max LED current of 250mA it gives a resolution of 8mA per step and so the lowest light output is 8mA at roughly 6V.

Since it does not use PWM the main controller can go to sleep once the current is set.

USB rechargable with build in charger

Microchip MCP73833, i still have some of them as well.

It provides a thermal cutoff while charging if the cell gets too hot with a NTC and it has 3 pin status output.

Not too expensive and i really like the 3 pin output.

It indicates "power good", "charging", "full" and "fault" with 4 different states instead of just a light that goes on and of.

User interface

Two buttons for power up/down and on/off or whatever idea i got, i do not want a single button.

One RGB charge indicator LED.

One dual color battery level indicator with rough battery level aproximation through cell voltage.

I never tried that and guesstimating the charge of a Li* cell by the voltage alone is not a good idea but it is all i can do with the selected components.

As a controller i have chosen the ATTiny85 because they are cheap, i want a bit more flash then a ATTiny13A and everything else is too expensive and big.

Other things

The cell needs to have a second protection circuit, i am toying with the idea of a Texas Instruments BQ29700 cell protection IC, it is fairly cheap but i hate soldering compoents without legs and this thing is tiny.

The whole, how will i mount and cool the LED is still a bit problematic but solveable.

The electronics should be fairly cheap, all on one PCB with all components on one side except the switches, if possible.

I may have to mount the switches and LEDs on the backside, i only work with 0805 SMD parts and hate leg-less packages, so i am stuck with bigger components.

With 0603 and QFN packages everything would fit on one side.

That is about it, what to you guys think?

Quite some time ago i sparked the idea to build a flashlight, it is a few months later now and i have a rough idea on how to do it.

In my parts bin are about ten 18650 cells, 20 LED drivers, a few Nichia LEDs and a 3D printer, all that needs to be put to good use.

So i am set on these four things, here is what i came up with so far, just made some prints to have something in my hand to play with:

http://imgur.com/qankruB

What i know so far, a 3D printed case seems to be viable (if printed in PETG), heat dissipation of the LED will be a problem, 18650 makes the light a bit too big then i would like to but i do not want to buy new batteries.

LED options:

Nichia NF2L385AR,170 Lumen, 2700K with 83RA

Nichia NF2W385AR,197 Lumen, 5000K with 83RA

Cree MK-R, 350 Lumen, 2700K with 80RA

I am unsure about a lens, either a whide angle or none at all, i want a floodlight.

If possible i want to put a temp sensor in there so the light can regulate the power down if it gets too hot, just a cheap NTC/Resistor solution.

LED Driver with no PWM

Texas Instruments TPS61165,i have 20 of them and they fit the LED nicely.

It has a digital interface and can regulate the current in 31 steps.

With a max LED current of 250mA it gives a resolution of 8mA per step and so the lowest light output is 8mA at roughly 6V.

Since it does not use PWM the main controller can go to sleep once the current is set.

USB rechargable with build in charger

Microchip MCP73833, i still have some of them as well.

It provides a thermal cutoff while charging if the cell gets too hot with a NTC and it has 3 pin status output.

Not too expensive and i really like the 3 pin output.

It indicates "power good", "charging", "full" and "fault" with 4 different states instead of just a light that goes on and of.

User interface

Two buttons for power up/down and on/off or whatever idea i got, i do not want a single button.

One RGB charge indicator LED.

One dual color battery level indicator with rough battery level aproximation through cell voltage.

I never tried that and guesstimating the charge of a Li* cell by the voltage alone is not a good idea but it is all i can do with the selected components.

As a controller i have chosen the ATTiny85 because they are cheap, i want a bit more flash then a ATTiny13A and everything else is too expensive and big.

Other things

The cell needs to have a second protection circuit, i am toying with the idea of a Texas Instruments BQ29700 cell protection IC, it is fairly cheap but i hate soldering compoents without legs and this thing is tiny.

The whole, how will i mount and cool the LED is still a bit problematic but solveable.

The electronics should be fairly cheap, all on one PCB with all components on one side except the switches, if possible.

I may have to mount the switches and LEDs on the backside, i only work with 0805 SMD parts and hate leg-less packages, so i am stuck with bigger components.

With 0603 and QFN packages everything would fit on one side.

That is about it, what to you guys think?

Last edited: