bstrickler

Enlightened

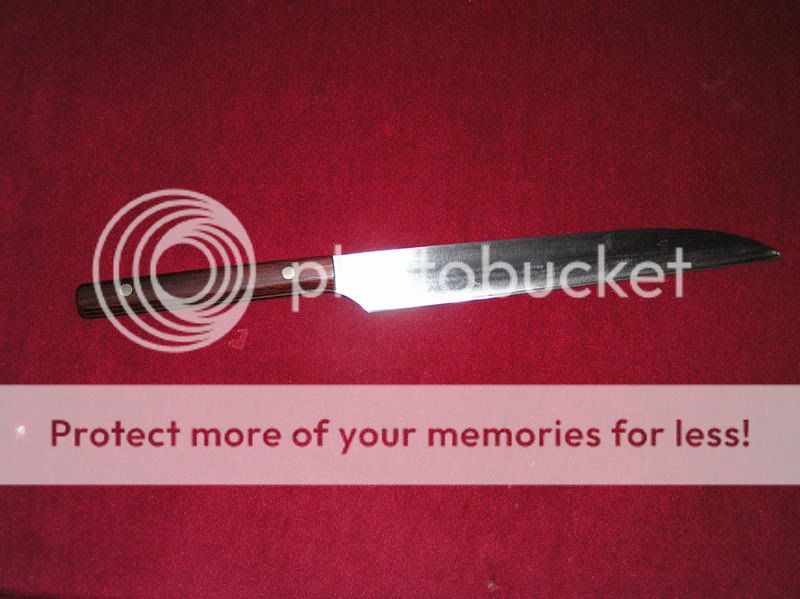

I recently aquired a 2 1/2" diameter by 5 1/2" long rod of D2 steel, and I'm taking a metalsmithing course this semester (will be retaking it in the fall, too). I plan to make many knives with it (and potentially daggers, if I get that far without it falling apart)

I've been doing some research, and it sounds like D2 is a nightmare to forge. Too hot, and it crumbles, too cold, and it cracks. Is it really that difficult to forge? Do you have any better explanation than temperatures (I don't have a thermometer that reads that high, so the temperature in degrees is utterly useless for me right now)? Things like "bright yellow, yellow-orange, orange, red-orange" will work for me, since it is a night class (hard to tell the temperatures during the day, in the Tucson sun!).

I will have access to a powerhammer, so that will allow me to get more drawing done than if I were doing it entirely by hand. Any estimates on how many seconds I can forge it with the powerhammer before I need to throw it back in?

If you're wondering why I chose D2, its because I've been reading up on it some, and it seems to be the best steel for holding an edge on a non-impact blade (impact meaning: swords, axes, etc, versus knives not really hitting/being hit by stuff). That, of course, was after I bought the steel (it was on sale )

)

Thanks,

Brian

I've been doing some research, and it sounds like D2 is a nightmare to forge. Too hot, and it crumbles, too cold, and it cracks. Is it really that difficult to forge? Do you have any better explanation than temperatures (I don't have a thermometer that reads that high, so the temperature in degrees is utterly useless for me right now)? Things like "bright yellow, yellow-orange, orange, red-orange" will work for me, since it is a night class (hard to tell the temperatures during the day, in the Tucson sun!).

I will have access to a powerhammer, so that will allow me to get more drawing done than if I were doing it entirely by hand. Any estimates on how many seconds I can forge it with the powerhammer before I need to throw it back in?

If you're wondering why I chose D2, its because I've been reading up on it some, and it seems to be the best steel for holding an edge on a non-impact blade (impact meaning: swords, axes, etc, versus knives not really hitting/being hit by stuff). That, of course, was after I bought the steel (it was on sale

Thanks,

Brian

Last edited: