You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electrical contact points in light head?

- Thread starter wyager

- Start date

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum

ti-force

Flashlight Enthusiast

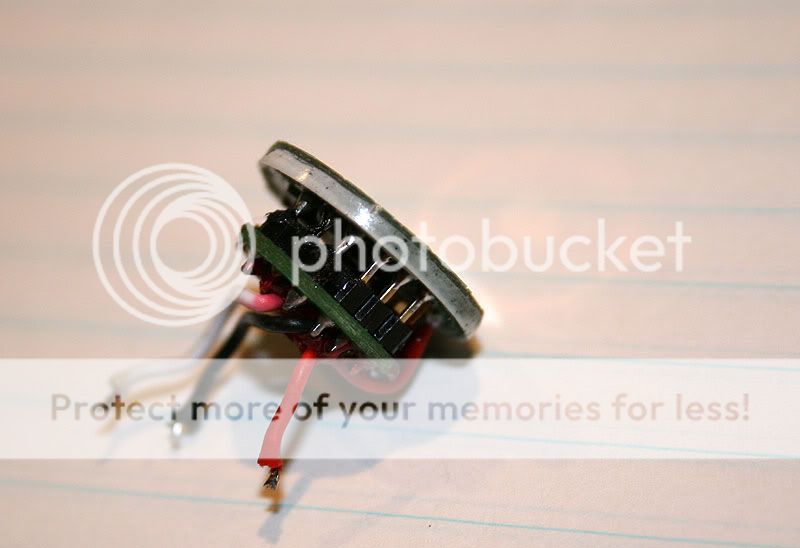

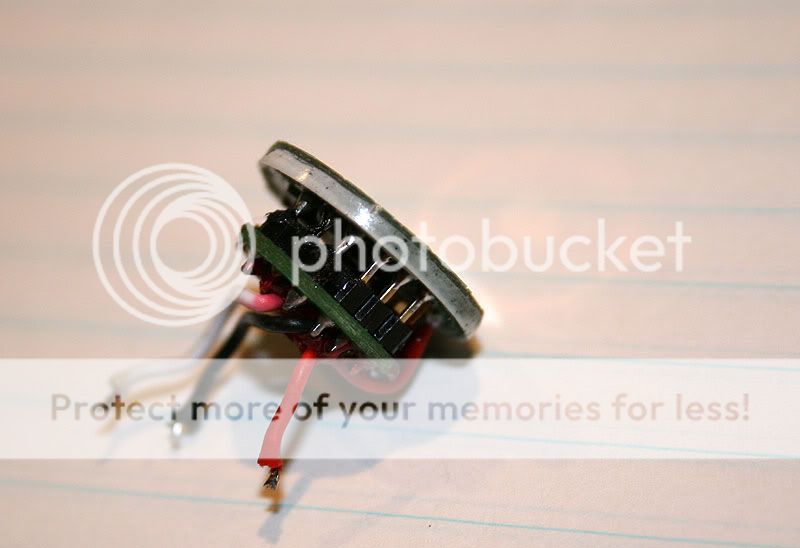

And this is what they look like on the other side  -

-

Last edited:

wyager

Flashlight Enthusiast

- Joined

- Feb 10, 2010

- Messages

- 1,114

Wow, they really butchered those DIP headers.... yeah, it looks like an ISP interface for programming the chip. What would be really cool is if they gave us .hex files we could use to switch between, say, tactical or standard heads by just reprogramming the lights  (please?). I suppose there could be a danger of having someone else copy their circuit design, but their interface isn't particularly hard to mimic....

(please?). I suppose there could be a danger of having someone else copy their circuit design, but their interface isn't particularly hard to mimic....

ti-force

Flashlight Enthusiast

Wow, they really butchered those DIP headers.... yeah, it looks like an ISP interface for programming the chip. What would be really cool is if they gave us .hex files we could use to switch between, say, tactical or standard heads by just reprogramming the lights(please?). I suppose there could be a danger of having someone else copy their circuit design, but their interface isn't particularly hard to mimic....

No habla espanol! English translation - I don't have a clue what you just said LOL....

What are DIP headers? Is that the six pins running from the bottom board to the top board?

Last edited:

Wow, they really butchered those DIP headers.... yeah, it looks like an ISP interface for programming the chip. What would be really cool is if they gave us .hex files we could use to switch between, say, tactical or standard heads by just reprogramming the lights(please?). I suppose there could be a danger of having someone else copy their circuit design, but their interface isn't particularly hard to mimic....

The .hex file is an extension that the asm(assembly) language is on. This is a language between humans and logic that is understood by microprocessors. Its basically another language that translates short words into logic that the computer understands. Its like .doc for word or .jpg for a picture. It takes some time with any language to understand and translate. The dip is the pins that interface with the chip, a plug etc. Isp is short for who knows what but my take is this thing hooks up like pic and does not need a special cord or adapter to interface with a computer to program or flash it.

It would be awesome in the future to have a bluetooth or some type of fruquency to reprogram without opening the flashlight. Or even a micro sd/wifi(or w/o wifi) slot so you can just reprogram it yourself without having to expose the guts or hook anything up. Then again this would be too easy, companies wouldn't like this at all.

wyager

Flashlight Enthusiast

- Joined

- Feb 10, 2010

- Messages

- 1,114

Basically. Sorry, sometime I forget I'm not on an electronics forumThe .hex file is an extension that the asm(assembly) language is on. This is a language between humans and logic that is understood by microprocessors. Its basically another language that translates short words into logic that the computer understands. Its like .doc for word or .jpg for a picture. It takes some time with any language to understand and translate. The dip is the pins that interface with the chip, a plug etc. Isp is short for who knows what but my take is this thing hooks up like pic and does not need a special cord or adapter to interface with a computer to program or flash it.

DIP header=metal pins that join circuits together

ISP=in-circuit serial programming-this is how you upload a program to a microchip

.hex file=the file you upload to the microchip that contains the program

I hope that clears it up. As for adding wifi/microSD to a light... that would take a lot of money, space, and time. It would be easier to add a simple serial interface.

ti-force

Flashlight Enthusiast

The .hex file is an extension that the asm(assembly) language is on. This is a language between humans and logic that is understood by microprocessors. Its basically another language that translates short words into logic that the computer understands. Its like .doc for word or .jpg for a picture. It takes some time with any language to understand and translate. The dip is the pins that interface with the chip, a plug etc. Isp is short for who knows what but my take is this thing hooks up like pic and does not need a special cord or adapter to interface with a computer to program or flash it.

It would be awesome in the future to have a bluetooth or some type of fruquency to reprogram without opening the flashlight. Or even a micro sd/wifi(or w/o wifi) slot so you can just reprogram it yourself without having to expose the guts or hook anything up. Then again this would be too easy, companies wouldn't like this at all.

Thanks for the explanation, and :welcome:.

It sounds like you're pretty knowledgeable with programming, and it would be neat if the user could link up with the light via bluetooth, or even using a cable and program different modes in a user chosen sequence.

Wyager,

I butchered up the DIP header

ti-force

Flashlight Enthusiast

Oh, I see, I was gonna say I'd never seen a factory soldering job melt plastic that badI'm gonna go read about your mod now....

.... Yeah, I think the melted plastic was a failed attempt by myself to unsolder the pins

.... Yeah, I think the melted plastic was a failed attempt by myself to unsolder the pins  , but I can't remember for sure. As you can see, I quickly put the soldering iron down and reached for the cutters to separate the boards

, but I can't remember for sure. As you can see, I quickly put the soldering iron down and reached for the cutters to separate the boards wyager

Flashlight Enthusiast

- Joined

- Feb 10, 2010

- Messages

- 1,114

Believe me, I've done that too... I have a little USB adapter that plugs in to prototyping boards and the plastic is barely hanging together........ Yeah, I think the melted plastic was a failed attempt by myself to unsolder the pins

, but I can't remember for sure. As you can see, I quickly put the soldering iron down and reached for the cutters to separate the boards

.