There had been some issues with the first version of the Lumens Factory D26 Led Module: Link

- Gap between head and body with the outer spring installed

- No function without the outer spring installed

- The led was not correct soldered

- The driver board did not fit correct into the brass housing

Yesterday I got two additional D26 modules (improved version) from Mark (Lumens Factory).

One was not glued (for a look inside).

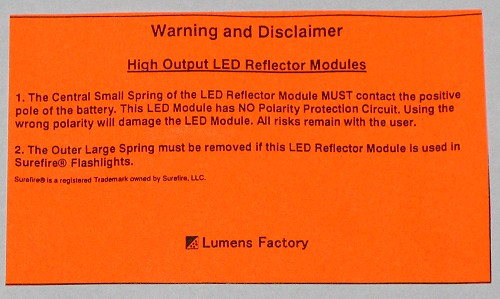

Disclaimer:

Comparison: Surefire 60L -- Lumens Factory D26

D26 Modules installed.

The small gap between head and body (approx. 0,5 mm) is ok. Without this gap there is not enough pressure for a correct electrical contakt.

(The Surefire P60L module don´t need this gap because of the installed outer spring)

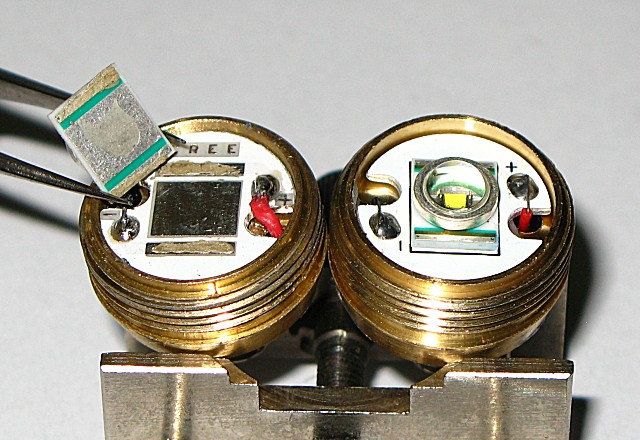

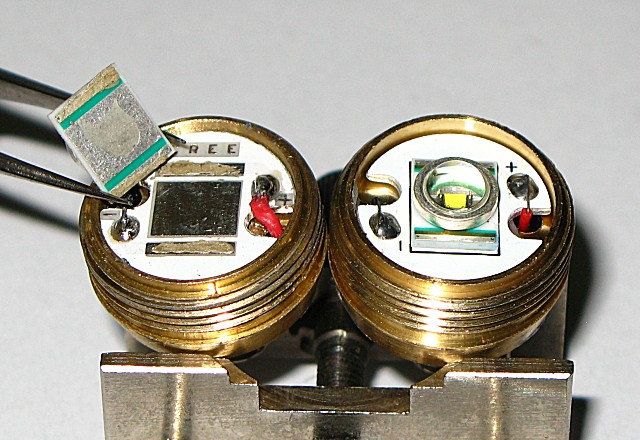

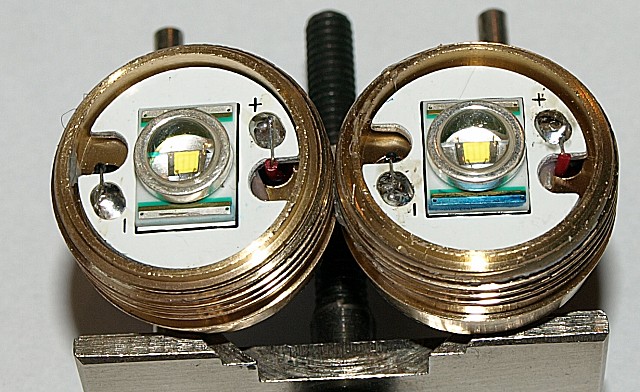

D26 old version (left) vs D26 improved version (right)

The driver board of the improved version fits exact.

Because of the three solder points the thermal contact to the light-body is not optimal

D26 old version (left) vs D26 improved version (right)

The Led of the old version was not soldered and came off easily. Soldering of the improved version is perfect

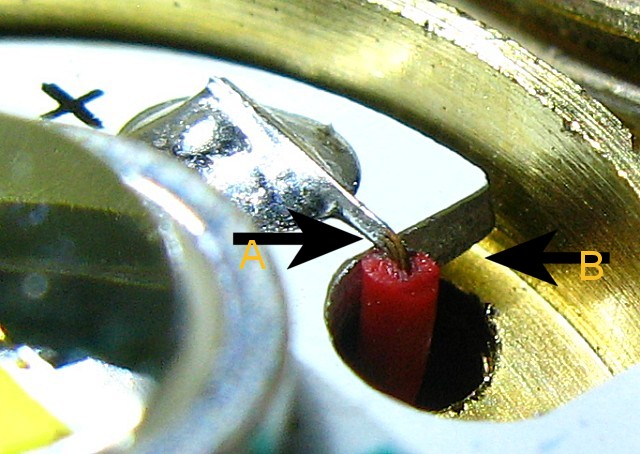

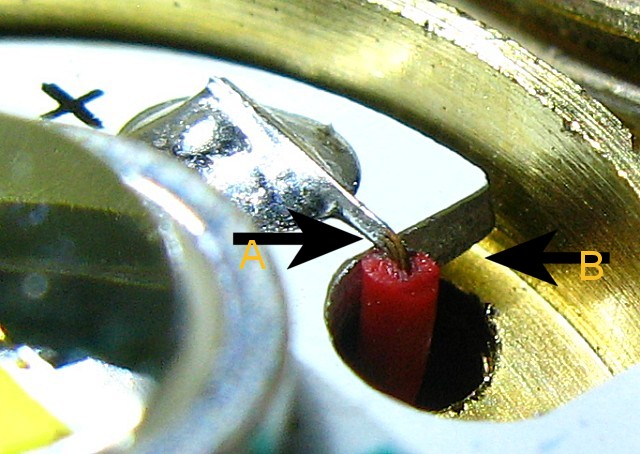

Two smaller issues:

- (A) the wires are very close to the led-board

- (B) the distance between led-board and brass housing is too big (too much thermal paste, thermal contact is not optimal)

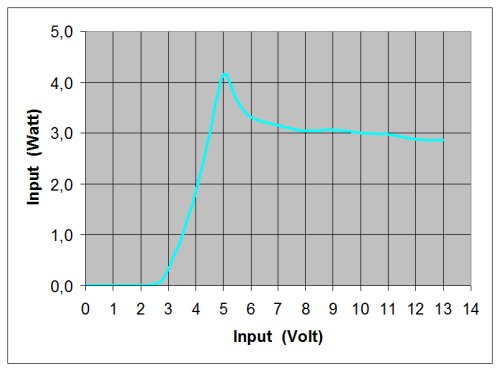

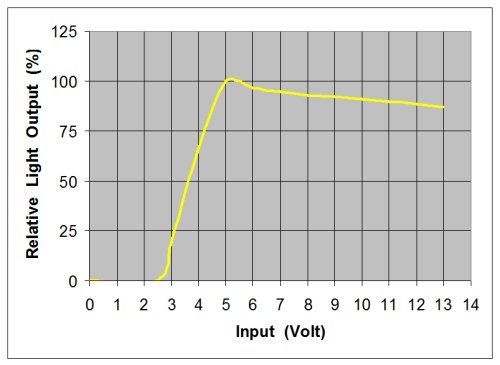

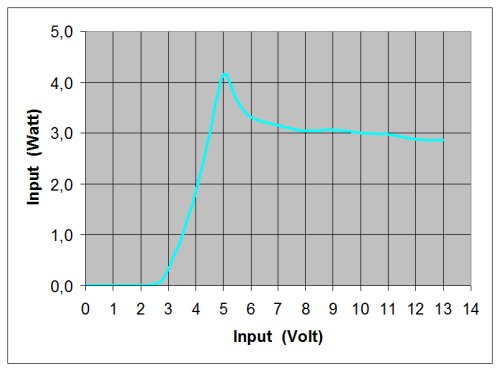

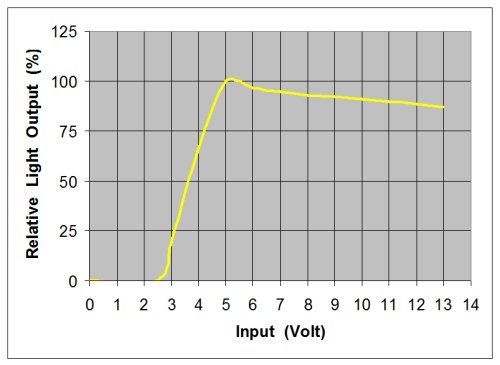

Regulation

Lumens-Factory says: 3,6V-13V, Regulated Input

The D26 module was installed in a Surefire C2 and connected to a regulated power supply (batteries removed).

As you can see, the module works nice above 4,5 V input.

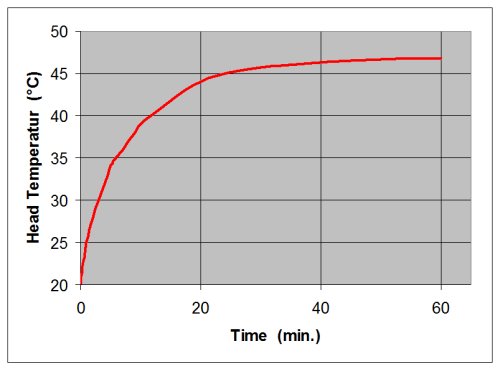

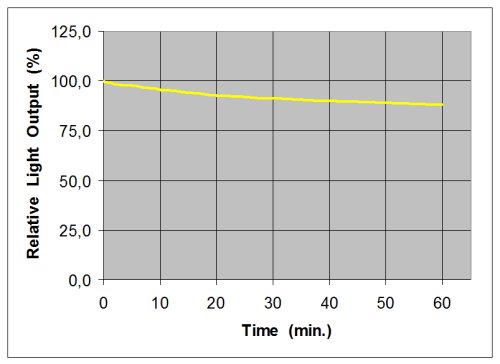

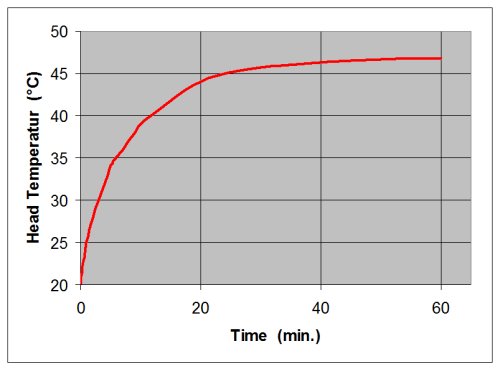

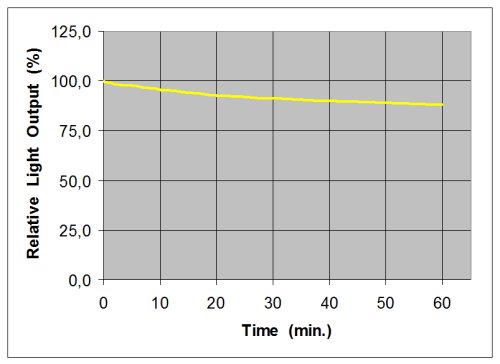

Thermal management

Because I was a bit skeptical about the thermal management of the module, I´ve made a continuous one hour test.

The module was installed in a Surefire C2 and connected to a power supply at 5V regulated.

Result: no issues found, the thermal mangement is ok

Conclusion:

The improved version of the Lumens Factory D26 led-module is ok.

- bright, good throw, useable spillbeam

- good regulation above 4,5 V

- no thermal issues found

- Gap between head and body with the outer spring installed

- No function without the outer spring installed

- The led was not correct soldered

- The driver board did not fit correct into the brass housing

Yesterday I got two additional D26 modules (improved version) from Mark (Lumens Factory).

One was not glued (for a look inside).

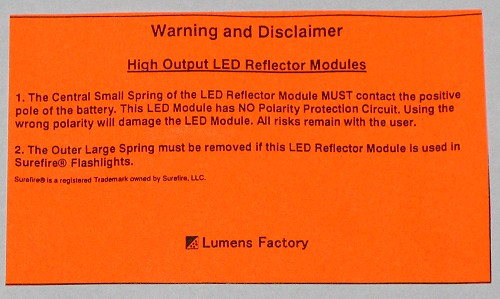

Disclaimer:

Comparison: Surefire 60L -- Lumens Factory D26

D26 Modules installed.

The small gap between head and body (approx. 0,5 mm) is ok. Without this gap there is not enough pressure for a correct electrical contakt.

(The Surefire P60L module don´t need this gap because of the installed outer spring)

D26 old version (left) vs D26 improved version (right)

The driver board of the improved version fits exact.

Because of the three solder points the thermal contact to the light-body is not optimal

D26 old version (left) vs D26 improved version (right)

The Led of the old version was not soldered and came off easily. Soldering of the improved version is perfect

Two smaller issues:

- (A) the wires are very close to the led-board

- (B) the distance between led-board and brass housing is too big (too much thermal paste, thermal contact is not optimal)

Regulation

Lumens-Factory says: 3,6V-13V, Regulated Input

The D26 module was installed in a Surefire C2 and connected to a regulated power supply (batteries removed).

As you can see, the module works nice above 4,5 V input.

Thermal management

Because I was a bit skeptical about the thermal management of the module, I´ve made a continuous one hour test.

The module was installed in a Surefire C2 and connected to a power supply at 5V regulated.

Result: no issues found, the thermal mangement is ok

Conclusion:

The improved version of the Lumens Factory D26 led-module is ok.

- bright, good throw, useable spillbeam

- good regulation above 4,5 V

- no thermal issues found

Last edited:

Just when things look better, something else comes up. :green:

Just when things look better, something else comes up. :green: