wquiles

Flashaholic

Short video of the head grooving process on one of my custom 1xD's. Note that although my lathe has about 1.5HP motor (Chinese HP?), you can definitely hear the lathe working a tad harder as I push the bit into the head:

Mag D Head Grooving

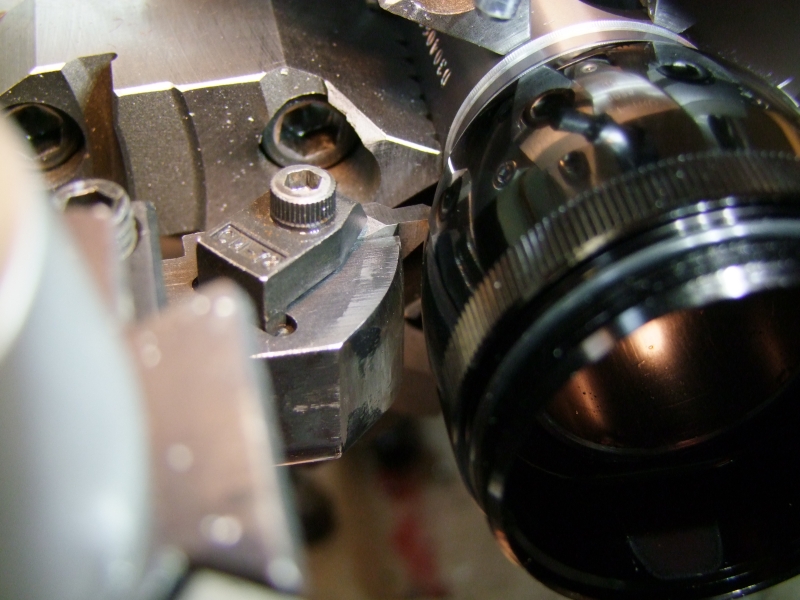

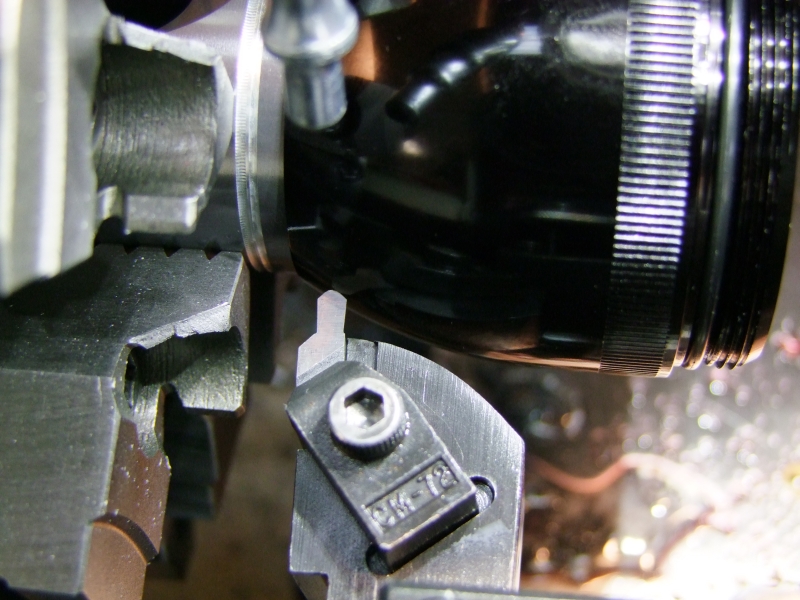

For the head, I had to grind the face of the tool somewhat to gain additional clearance:

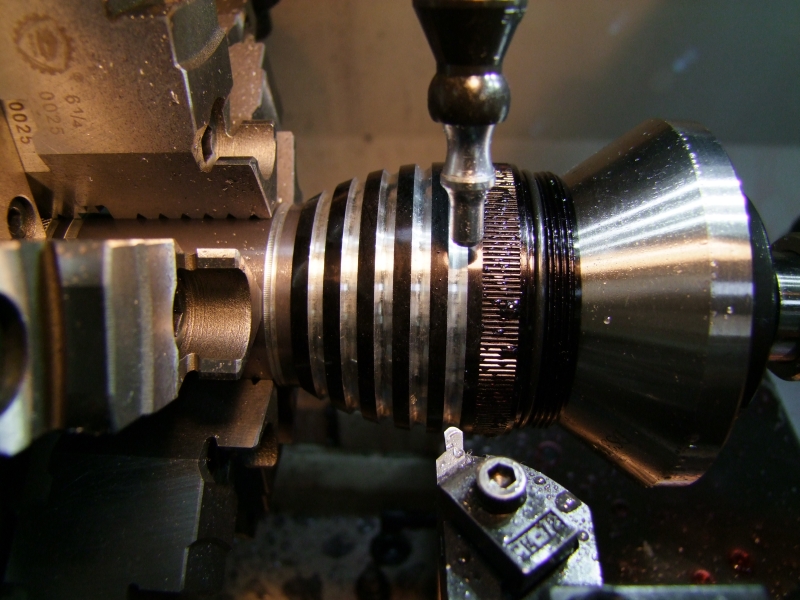

Here is the completed head:

Short movie of the body grooving process on one of my custom 1xD's. Here the cut is so light/shallow that the lathe hardly notices:

Mag D Body Grooving

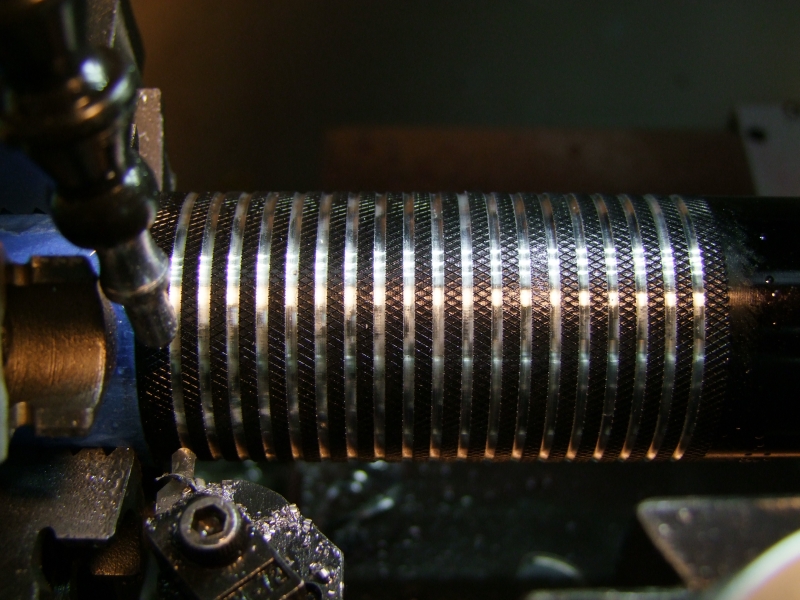

Here is how it looks when I am done:

Will

Mag D Head Grooving

For the head, I had to grind the face of the tool somewhat to gain additional clearance:

Here is the completed head:

Short movie of the body grooving process on one of my custom 1xD's. Here the cut is so light/shallow that the lathe hardly notices:

Mag D Body Grooving

Here is how it looks when I am done:

Will

Last edited: