Roland Gama

Newly Enlightened

- Joined

- Aug 29, 2008

- Messages

- 83

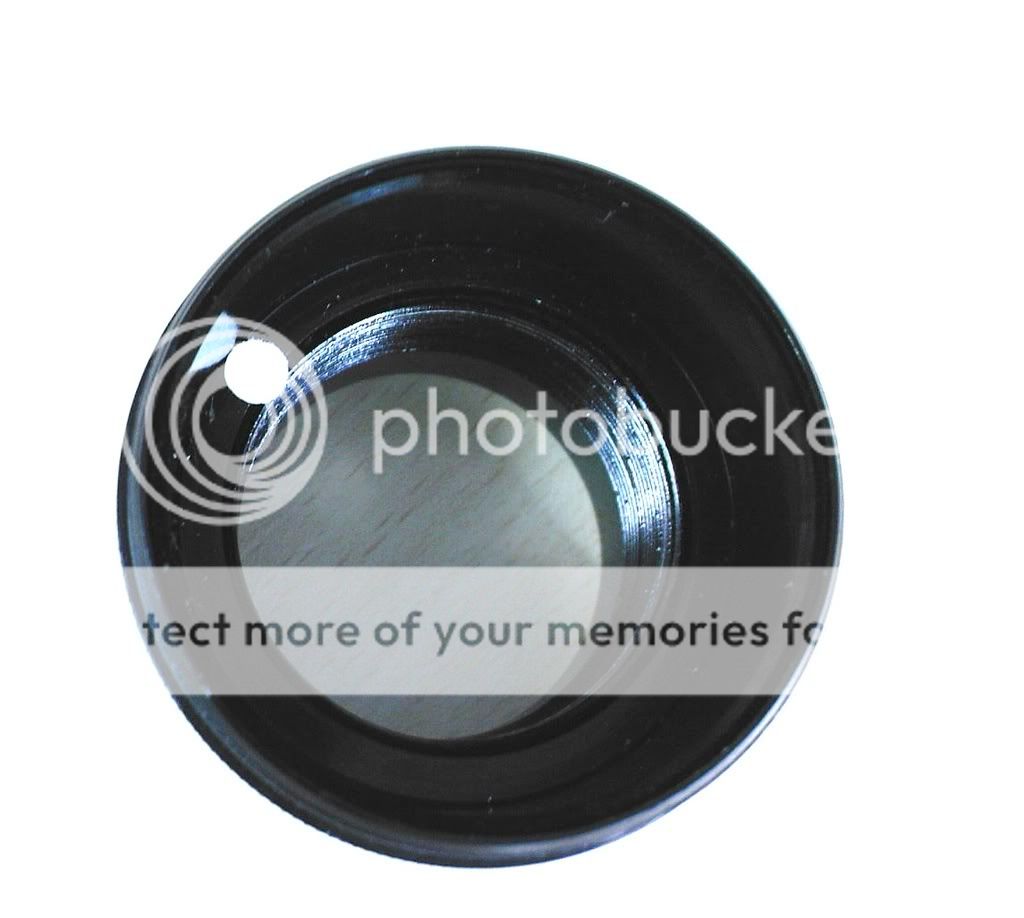

Can anyone give some detailed info on the sputtering technique?

Taking a 2k clear coat polyurethane paint and a De vilbiss spot repair gun into account does one look forward to a clear even film on the reflector? If so, then would one thin coat be okay or would several coats so a better job?

Secondly, if the spray gun is run at about half the required pressure and a quick single pass with the gun would give a mottled finish. Is this what I should look for?

Thanks in advance.

Taking a 2k clear coat polyurethane paint and a De vilbiss spot repair gun into account does one look forward to a clear even film on the reflector? If so, then would one thin coat be okay or would several coats so a better job?

Secondly, if the spray gun is run at about half the required pressure and a quick single pass with the gun would give a mottled finish. Is this what I should look for?

Thanks in advance.