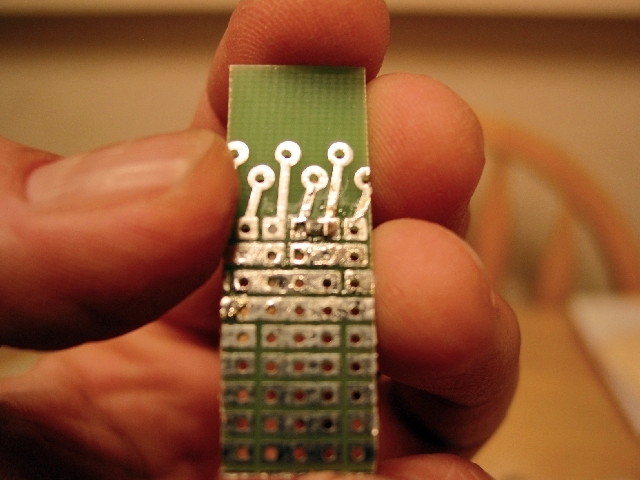

Here are the results of my first SMT practice attempt. Got me a 15 watt fine-tip iron (conical) at Rat Shack, and it was time to dig in.

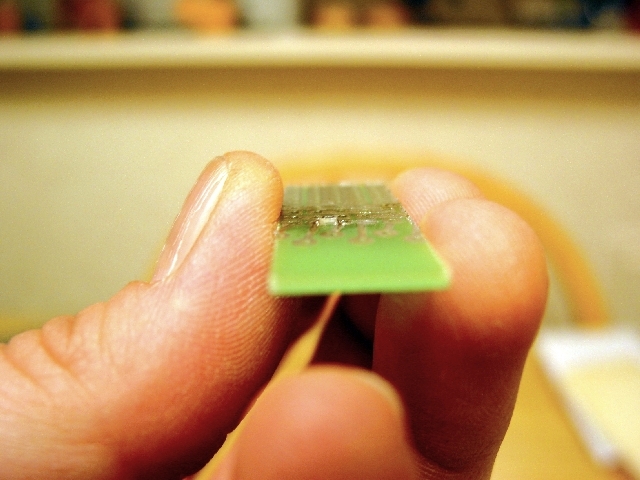

This is using the 222 resistor. Haven't tried the even more miniscule 150 yet... at least I think that's what it says... it's just a wee bit too small to read without a magnifying glass. I really cooked the crap out of this thing. A couple of times I managed to get it stuck to the iron, and it didn't want to shake off. However, using a toothpick and fingertips (ouch!), I was able to get it across two contacts on the pcb.

Doing this was a lot of fun, and a big learning experience. Trial and error quickly provided some observations, and revealed a few do's and don'ts. One thing I thought was neat, was that after the first attempt didn't come out well, I took the resistor back off to try again, and noticed that the little contacts on the bottom were now perfectly tinned! The solder apparently cannot stick to the material in between (ceramic?... silicon?), and actually seems to flow

away from it! Cool discovery for a SMT soldering noob. Also got to use a solder wick for the first time.

With a little more practice, some helpful tools like tweezers, magnifying glass, etc., I'll be ready to try those half a gnat turd size items.

Thanks again, Doug! Really appreciate your GB for this stuff, and wound up using the paste on one of my mods (attaching leads to a bFlex driver). It worked great!