so things are pretty much working properly? That would be a relief!

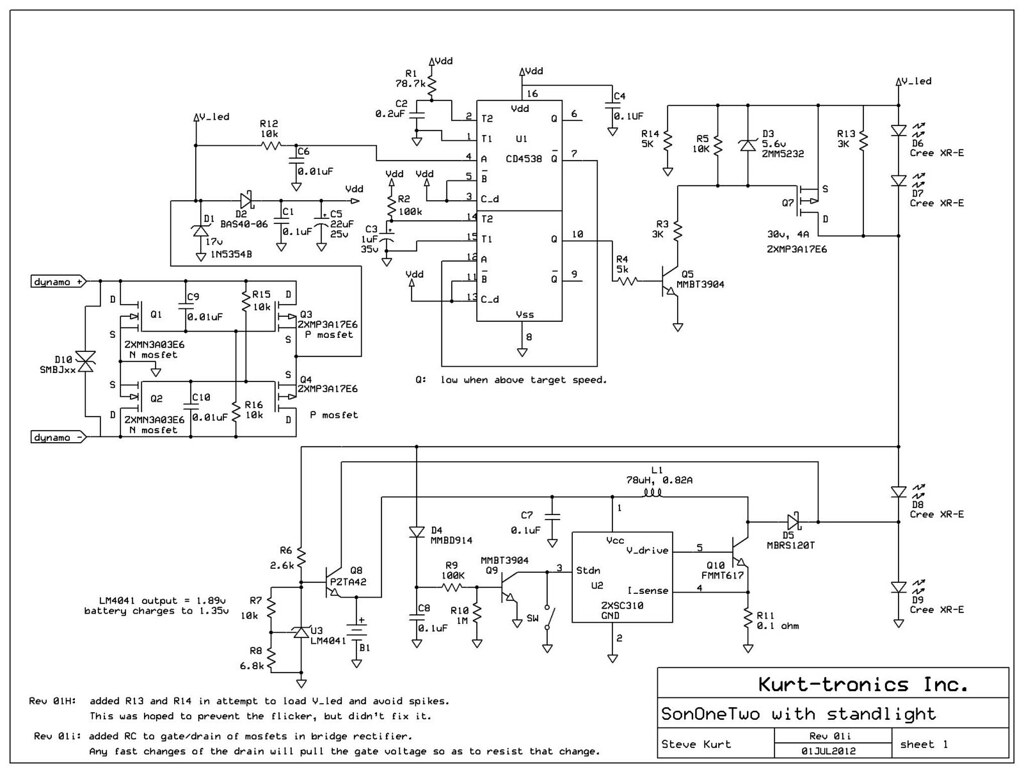

The interaction between the LEDs and the mosfets in the bridge rectifier were a surprise to me, and I was fairly happy to come up with a fix for my light. I didn't bother to consider what might happen with much larger LEDs.

However.... it wouldn't surprise me to learn that the larger LEDs might disrupt the careful balance I achieved with the caps I added at the mosfet gates. The original problem was related to the part of the dynamo's AC output, where the voltage was decreasing. At certain speeds, the rate of decrease of the voltage caused (IIRC) the mosfets to shut off. While the mosfets were shutting off, the current through the LEDs decreased, which removed the load from the dynamo, which caused the dynamo voltage to increase, which caused the mosfets to turn back on, which caused the LEDs to start conducting, which caused the dynamo output voltage to drop, causing the mosfets to turn off, etc....

Adding the caps to the mosfet gates slowed down the turn-off, which reduced the amount of feedback between the LEDs, dynamo, and mosfets. If you have the patience, you might try increasing the value of the caps. Perhaps increase from 0.01uF to 0.022uF? Or just solder another 0.01uf on top of the ones already on the board.

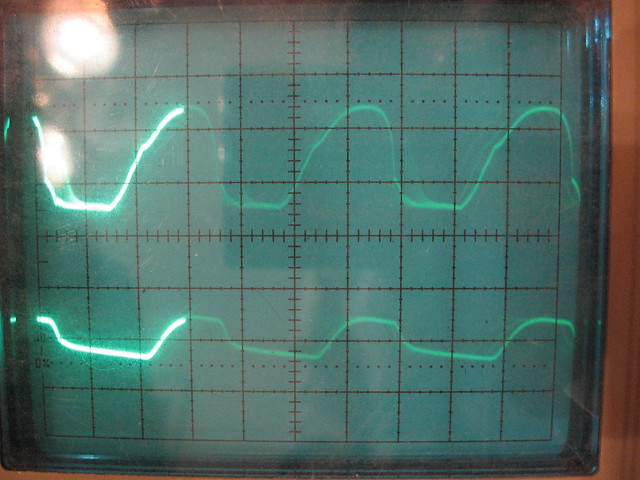

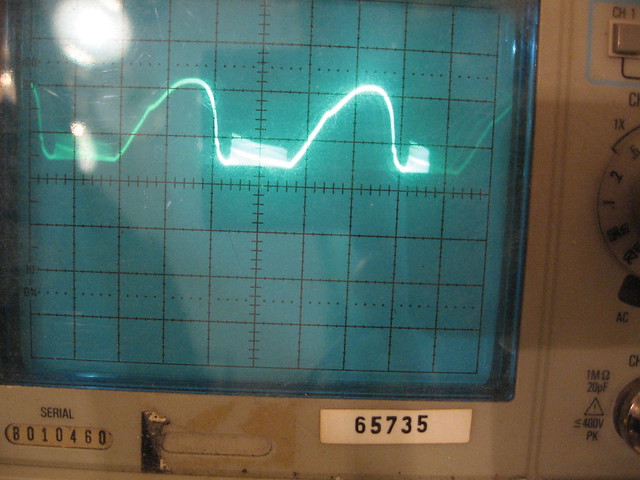

to answer an earlier question... the rectified dynamo voltage that is connected to the LEDs has quite a bit of ripple.. it goes all the way back to zero volts as the dynamo's AC voltage crosses 0 volts.

Here's a scope shot of the rectified voltage:

I'd have to dig through my notes to see what the conditions are.

Without the caps at the mosfet gates, the quick switching of the mosfets on and off caused some nasty spikes on the rectified voltage, which was messing up the circuit that measured the dynamo frequency and producing the flicker that I saw....

A scope is a very handy thing to have!! It's hard to justify the purchase if you are just building one project, though.

Going back to your earlier post again.. the mosfets in the bridge rectifier aren't blocking reverse current flow, so you can't add a filter cap. You could add a series diode, preferably a schottky, and then add a filter cap. That might be an interesting exercise.

Regarding your quad LED optics... it can't produce a nice tight beam, can it? I find that I prefer a very tight beam, such as the Ledil Rocket smooth spot, which produces a beam that is +/- 4 degrees FWHM (full width half maximum). My guess is that your reflector produces a much wider beam, and the dark spot might just be the image of the center of your LED group.

!!

!!