Doug S

Flashlight Enthusiast

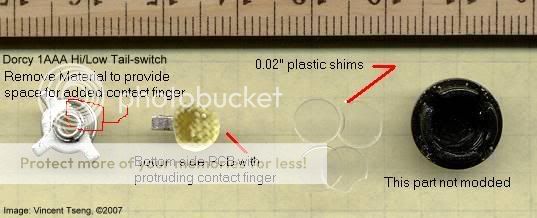

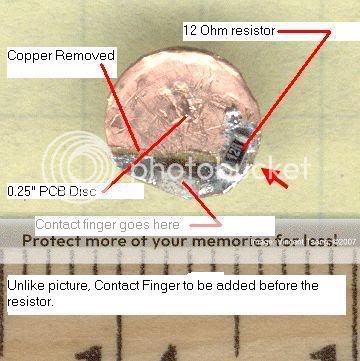

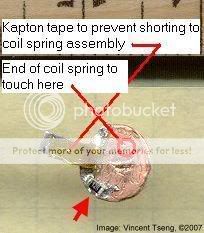

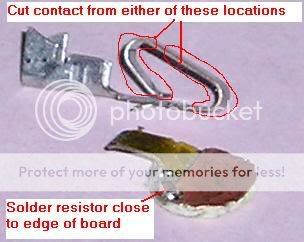

This thread is intended to show how to do some high benefit modifications to the circuit in the currently available Dorcy 1AAA LED flashlight which has been referred to on these forums as the Gen 3 and/or 4 Dorcy 1AAA. This light has been discussed extensively in this thread:

https://www.candlepowerforums.com/threads/107794

The modifications reviewed in this thread:

https://www.candlepowerforums.com/posts/1804176#post1804176

And the technical details of these mods discussed in this thread:

https://www.candlepowerforums.com/posts/1815020#post1815020

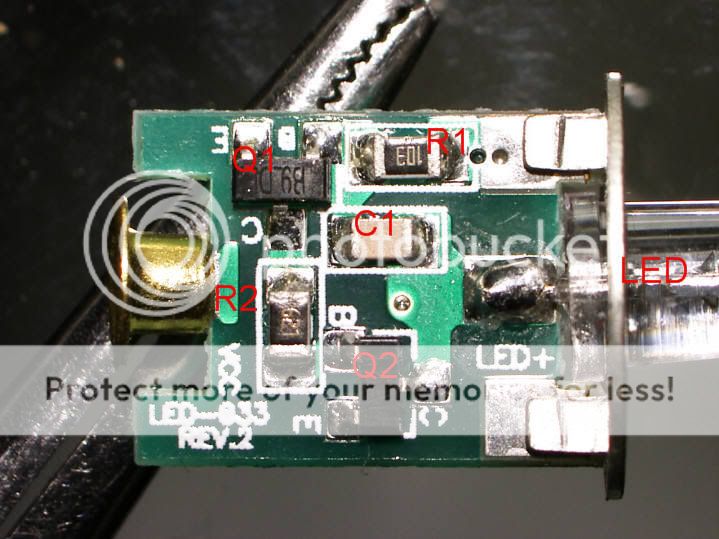

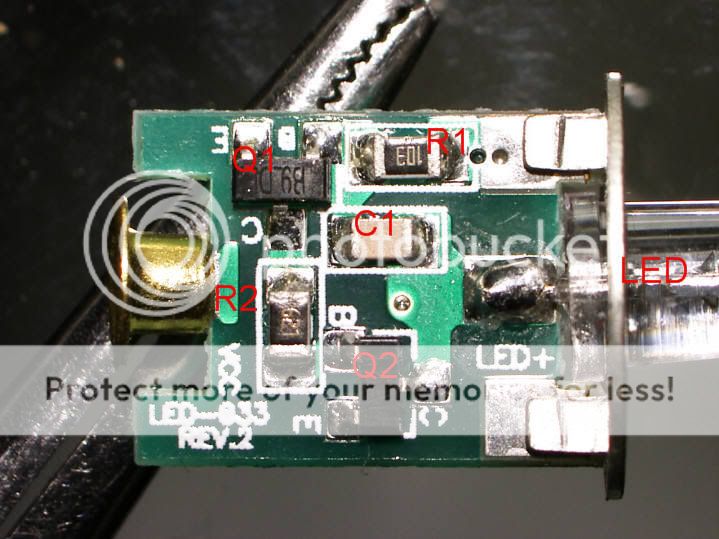

Here are some images of the front and back of the stock circuit board:

The images directly above were kindly provided by CPF member 1331.

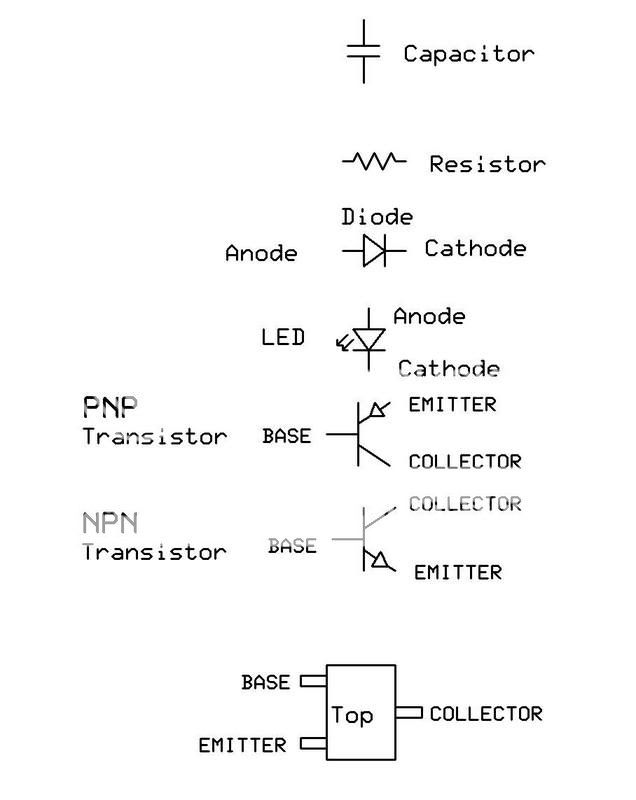

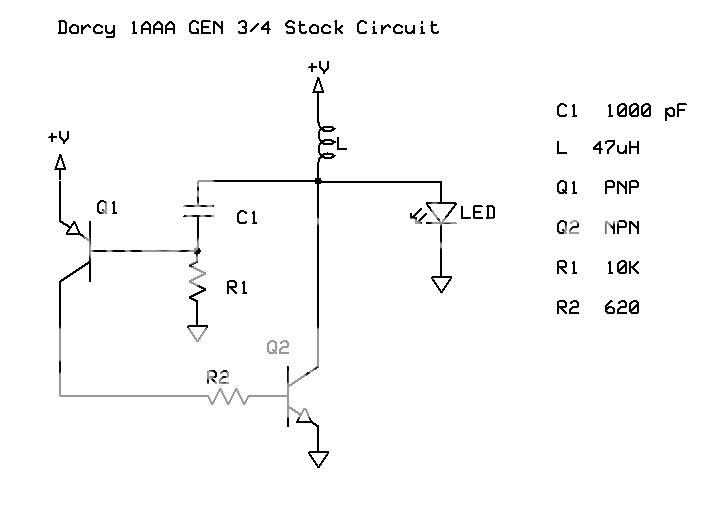

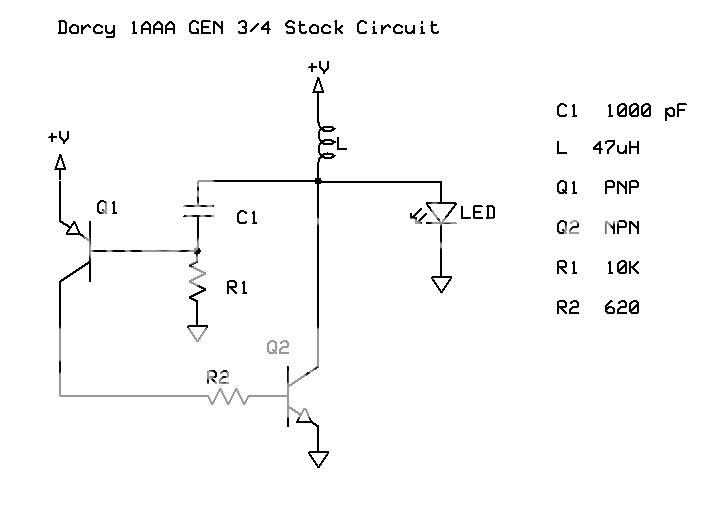

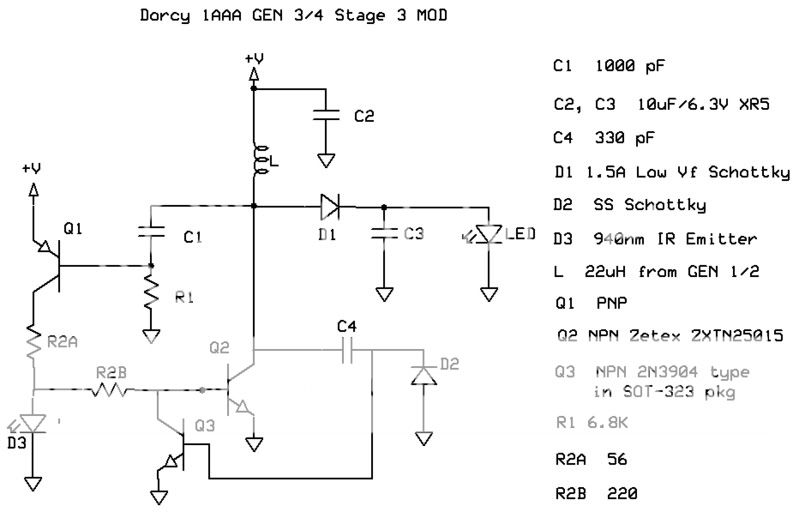

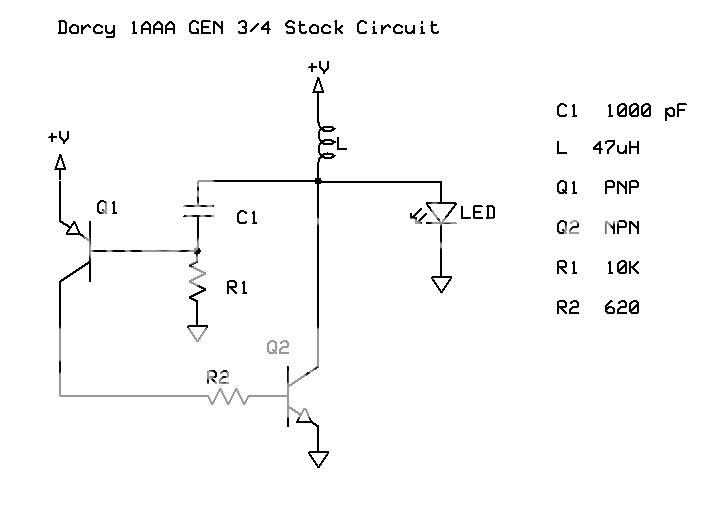

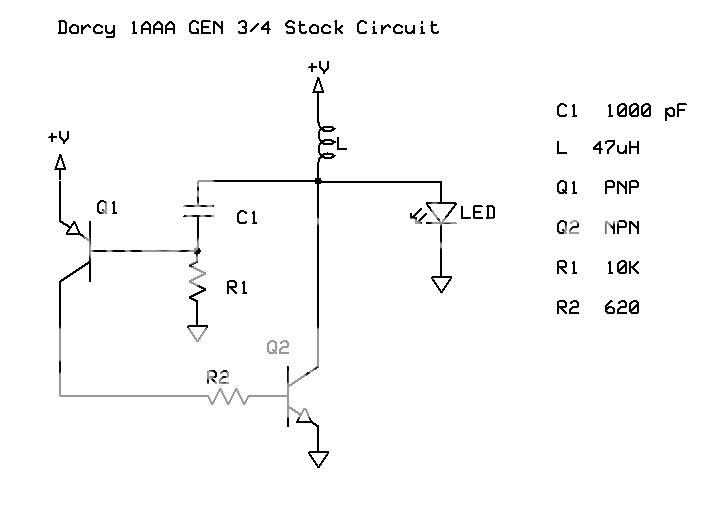

Here are the schematics for the stock circuit as well as the three versions of the mod referred to as stages 1, 2, and 3.

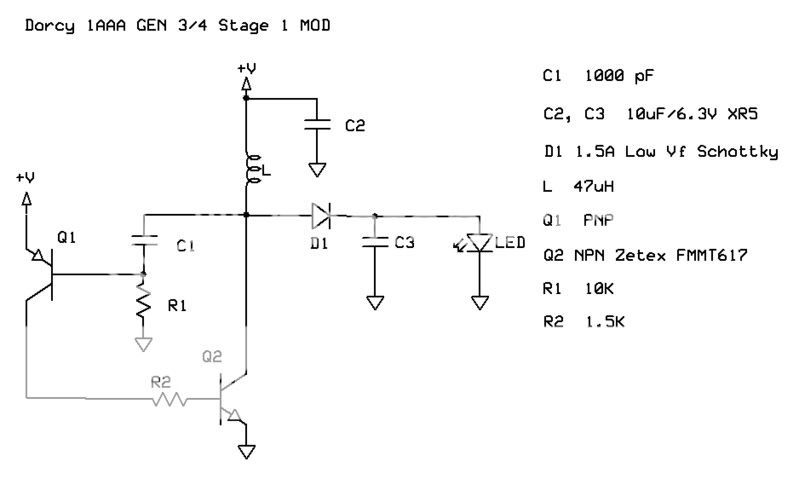

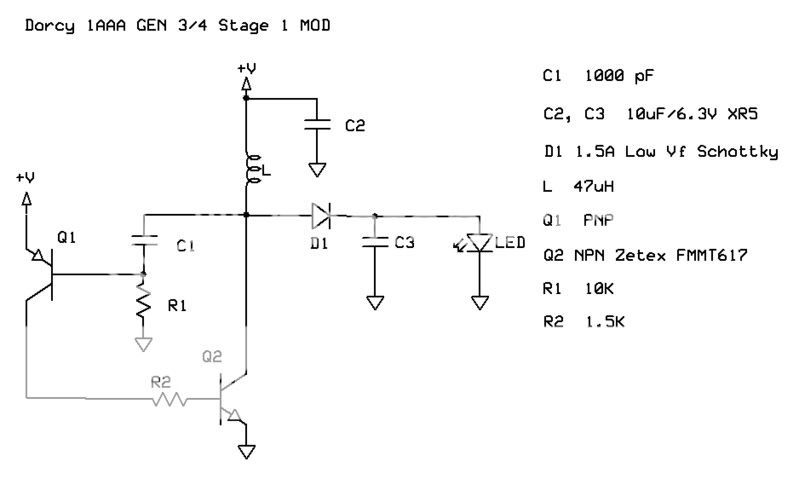

STAGE 1 MOD:

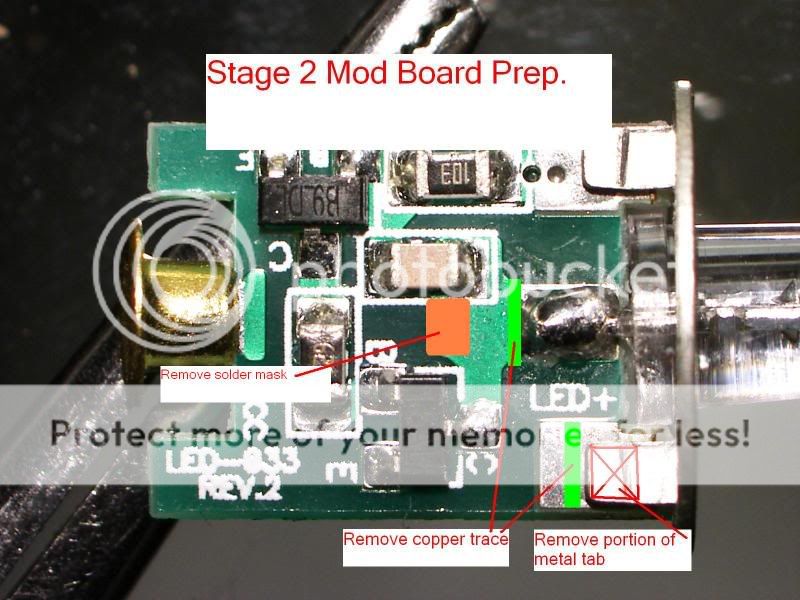

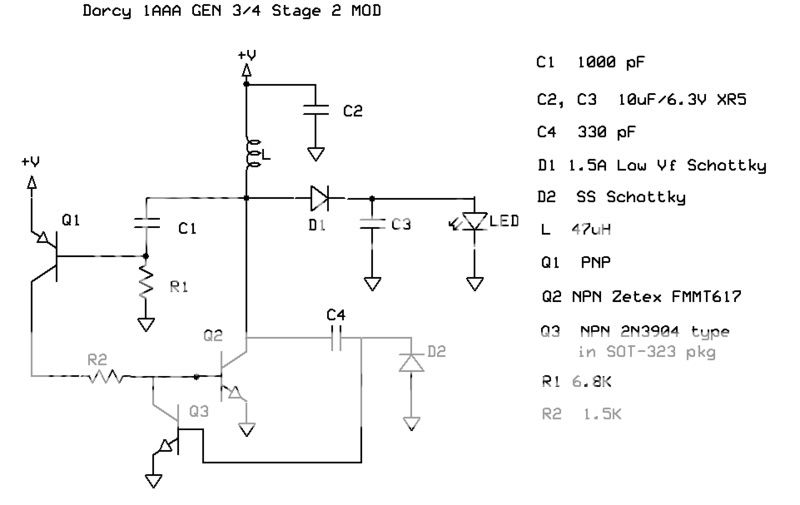

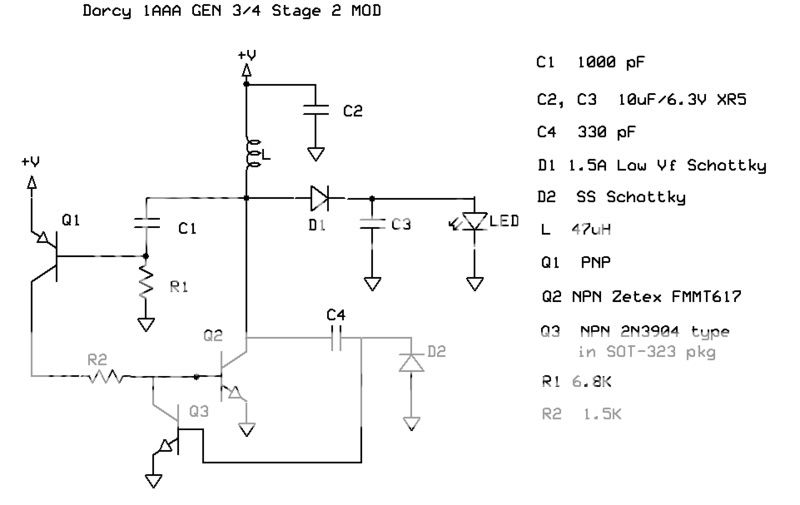

STAGE 2 MOD:

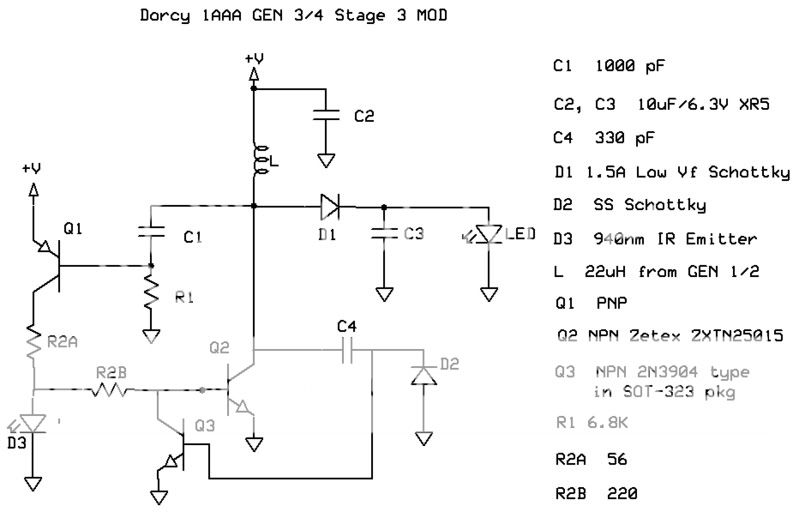

STAGE 3 MOD:

There is no significance to the use of the FMMT617 for Q2 in stages 1&2 and the ZXTN25015 in stage 3. At this point I was experimenting with various Q2 replacements. They are equally good but I think the FMMT617 is more widely available. Here is a link for the FMMT617 datasheet:

http://www.zetex.com/3.0/pdf/FMMT617.pdf

Capacitor C4 for stages 2&3 is listed as 330pF but any value from 100 to 1000pF is fine. In stage 2, R2 is shown as changed to 6.8K but this is not really necessary. It can be left at its stock value of 10K.

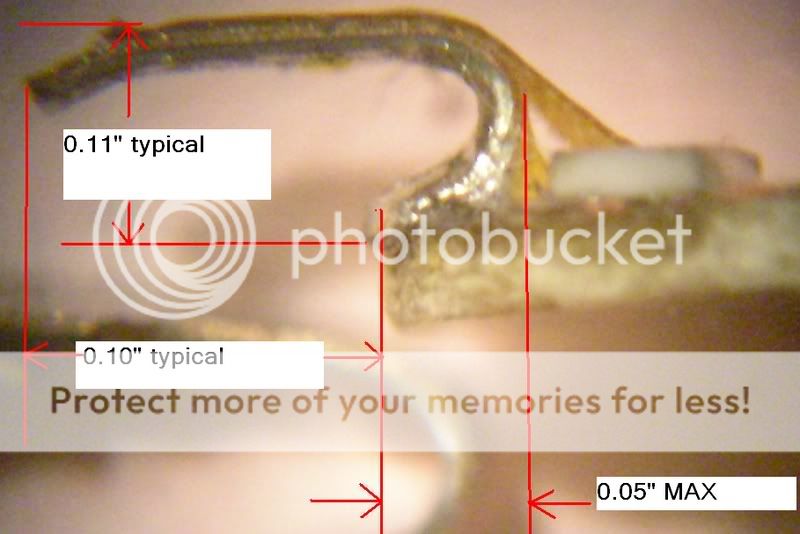

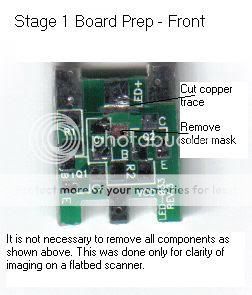

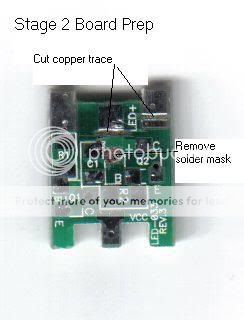

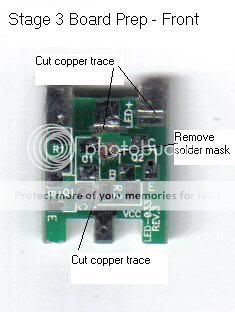

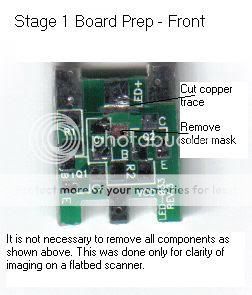

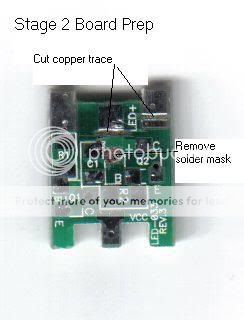

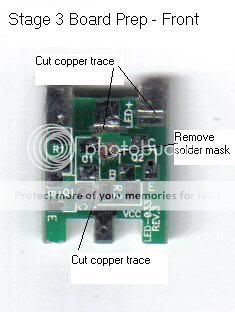

My primary means of reconfiguring the stock board to accommodate the new components is by cutting gaps in the existing copper traces and also scraping away the green solder mask material from the traces to create new locations to which a component can be soldered. Here are some flatbed scanner images of the boards prepped for receiving the new components. Sorry about the image quality. I don't own a camera. For the purpose of making these images, I removed all components. This is not necessary for doing the mods.

For cutting the traces, an Exacto type knife with the smallest blade may be adequate. I prefer and use a #15 scalpel. FWIW, scalpels come in a wide variety of sizes and blade shapes with a standardized numerical nomenclature. I've tried many, I prefer the #15 for this type of work. Here is a link to an Ebay auction that contains a diagram of the scalpel blade types and sizes. This is not an endorsement of this seller. This link for illustration purposes only:

http://cgi.ebay.com/100-Scalpel-Bla...yZ104229QQssPageNameZWDVWQQrdZ1QQcmdZViewItem

Note, that particular auction is for blades only which fit in a reusable handle. More convenient is to buy disposable scalpels which have a handle attached.

The cheapest combination of price plus shipping for small quantities that I've seen is here:

http://cgi.ebay.com/Scalpel-disposa...oryZ3142QQrdZ1QQssPageNameZWD1VQQcmdZViewItem

It looks like if you buy seven the delivered cost is a dollar each. I'd be willing to add this to the group buy a $1/each if one were to evolve from this thread.

The idea of using these modifications as a tutorial project for folks who want to try their hand at modifications that require working with SMT components was discussed a bit in one of the other Dorcy 1AAA threads. All parts that you would need to purchase to do the Stage 2 mod come in at under $5 and are all available from one Electronics catalog retailer, Digikey. There are a couple of complications though if you are not already ordering parts from them for other reasons. There is a $5 surcharge for orders under $25 and shipping will run $5-8 depending on where you are. Also, some of the parts have a minimum purchase quantity of 10. If there is sufficient interest in this to where I likely won't be left holding the bag of parts I don't need, I could do a little mini-group buy of the parts, assort them into ''Kits'', and ship them for on the order of $5-6 for the first kit and well under $5 for a second since about $1.50 of the $5-6 figure includes the postage and packing costs. While this *may* be an inexpensive way to try your hand at working with SMT components, this assumes that you already have the minimal level of tools required. If you need to acquire lots of tools to do this, these could be very expensive lights indeed! On the other hand, you may be the sort that is always looking for a justification for buying new tools. If so, I, as well as others here, can help with recommendations for emptying your wallet on this project. If you have the inclination to buy off of Ebay, you can get an excellent soldering system for less that what some folks around here spend on a single flashlight. That system will still be excellent long after that flashlight is obsolete. How's that for a justification for redirecting some of your expenditures to quality tools?

Here is what I will do. I will keep the discussion of the Electronic/technical aspects of these mods in the thread over in the Electronics subforum. I will keep the step by step ''nuts and bolts'' aspect of doing these mods as well as a bit of tutorial instruction for folks without much/any experience with hand soldering SMT components in this thread. I will include suggestions for minimal level of tools required. Based on this thread, folks can decide whether they want to give it a go and express interest in this thread in the form of ''I'd take a kit'' or ''I'd take X kits'' if done as a group buy. Once there appears to be a critical mass of interest I would start a group buy thread to handle the transaction stuff so that this thread can remain focused on helping folks achieve success doing the actual mods. If there is interest I would be willing to include in the group buy effort a couple of inexpensive tool/supply items that some folks likely would need but are unlikely to be readily available locally or in small quantities [at the moment the two possible items that come to mind are scalpels and SMT solder paste]. Sound reasonable?

I'll follow with a post on tools and techniques. In the meantime, there was a bit of SMT hand soldering tutorial discussion here:

https://www.candlepowerforums.com/threads/149262

https://www.candlepowerforums.com/threads/107794

The modifications reviewed in this thread:

https://www.candlepowerforums.com/posts/1804176#post1804176

And the technical details of these mods discussed in this thread:

https://www.candlepowerforums.com/posts/1815020#post1815020

Here are some images of the front and back of the stock circuit board:

The images directly above were kindly provided by CPF member 1331.

Here are the schematics for the stock circuit as well as the three versions of the mod referred to as stages 1, 2, and 3.

STAGE 1 MOD:

STAGE 2 MOD:

STAGE 3 MOD:

There is no significance to the use of the FMMT617 for Q2 in stages 1&2 and the ZXTN25015 in stage 3. At this point I was experimenting with various Q2 replacements. They are equally good but I think the FMMT617 is more widely available. Here is a link for the FMMT617 datasheet:

http://www.zetex.com/3.0/pdf/FMMT617.pdf

Capacitor C4 for stages 2&3 is listed as 330pF but any value from 100 to 1000pF is fine. In stage 2, R2 is shown as changed to 6.8K but this is not really necessary. It can be left at its stock value of 10K.

My primary means of reconfiguring the stock board to accommodate the new components is by cutting gaps in the existing copper traces and also scraping away the green solder mask material from the traces to create new locations to which a component can be soldered. Here are some flatbed scanner images of the boards prepped for receiving the new components. Sorry about the image quality. I don't own a camera. For the purpose of making these images, I removed all components. This is not necessary for doing the mods.

For cutting the traces, an Exacto type knife with the smallest blade may be adequate. I prefer and use a #15 scalpel. FWIW, scalpels come in a wide variety of sizes and blade shapes with a standardized numerical nomenclature. I've tried many, I prefer the #15 for this type of work. Here is a link to an Ebay auction that contains a diagram of the scalpel blade types and sizes. This is not an endorsement of this seller. This link for illustration purposes only:

http://cgi.ebay.com/100-Scalpel-Bla...yZ104229QQssPageNameZWDVWQQrdZ1QQcmdZViewItem

Note, that particular auction is for blades only which fit in a reusable handle. More convenient is to buy disposable scalpels which have a handle attached.

The cheapest combination of price plus shipping for small quantities that I've seen is here:

http://cgi.ebay.com/Scalpel-disposa...oryZ3142QQrdZ1QQssPageNameZWD1VQQcmdZViewItem

It looks like if you buy seven the delivered cost is a dollar each. I'd be willing to add this to the group buy a $1/each if one were to evolve from this thread.

The idea of using these modifications as a tutorial project for folks who want to try their hand at modifications that require working with SMT components was discussed a bit in one of the other Dorcy 1AAA threads. All parts that you would need to purchase to do the Stage 2 mod come in at under $5 and are all available from one Electronics catalog retailer, Digikey. There are a couple of complications though if you are not already ordering parts from them for other reasons. There is a $5 surcharge for orders under $25 and shipping will run $5-8 depending on where you are. Also, some of the parts have a minimum purchase quantity of 10. If there is sufficient interest in this to where I likely won't be left holding the bag of parts I don't need, I could do a little mini-group buy of the parts, assort them into ''Kits'', and ship them for on the order of $5-6 for the first kit and well under $5 for a second since about $1.50 of the $5-6 figure includes the postage and packing costs. While this *may* be an inexpensive way to try your hand at working with SMT components, this assumes that you already have the minimal level of tools required. If you need to acquire lots of tools to do this, these could be very expensive lights indeed! On the other hand, you may be the sort that is always looking for a justification for buying new tools. If so, I, as well as others here, can help with recommendations for emptying your wallet on this project. If you have the inclination to buy off of Ebay, you can get an excellent soldering system for less that what some folks around here spend on a single flashlight. That system will still be excellent long after that flashlight is obsolete. How's that for a justification for redirecting some of your expenditures to quality tools?

Here is what I will do. I will keep the discussion of the Electronic/technical aspects of these mods in the thread over in the Electronics subforum. I will keep the step by step ''nuts and bolts'' aspect of doing these mods as well as a bit of tutorial instruction for folks without much/any experience with hand soldering SMT components in this thread. I will include suggestions for minimal level of tools required. Based on this thread, folks can decide whether they want to give it a go and express interest in this thread in the form of ''I'd take a kit'' or ''I'd take X kits'' if done as a group buy. Once there appears to be a critical mass of interest I would start a group buy thread to handle the transaction stuff so that this thread can remain focused on helping folks achieve success doing the actual mods. If there is interest I would be willing to include in the group buy effort a couple of inexpensive tool/supply items that some folks likely would need but are unlikely to be readily available locally or in small quantities [at the moment the two possible items that come to mind are scalpels and SMT solder paste]. Sound reasonable?

I'll follow with a post on tools and techniques. In the meantime, there was a bit of SMT hand soldering tutorial discussion here:

https://www.candlepowerforums.com/threads/149262

Last edited: