In thread - MJLED strobing?...

[ QUOTE ]

wwglen said:a "Homemade" MJLED. This is a high power 100mA 5mm LED I got from a group buy, ground down using a dremal tool. Looks rough but the three I have are about the same (brightness and beam shape) as the third gen MJLEDs I got.

[/ QUOTE ]

I did the shameless thing and begged wwglen for one of his homemade MJLEDs.

The wwglen home made MJLED arrived in the mail today, many thanks to wwglen for your generosity.

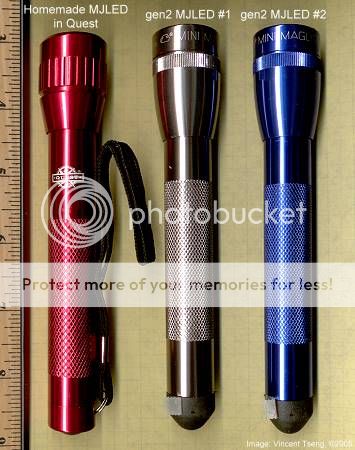

So I cut the legs to about 7/16" from the plastic dome base (just like I did with my previous MJLEDs) and replaced the MJLED in turn with each of my 2 gen2 MJLED MiniMag 2AAs for my comparisons.

Please see this thread -

MJLED drop-in for MiniMag 2AA

wwglen's Homemade MJLED installed -

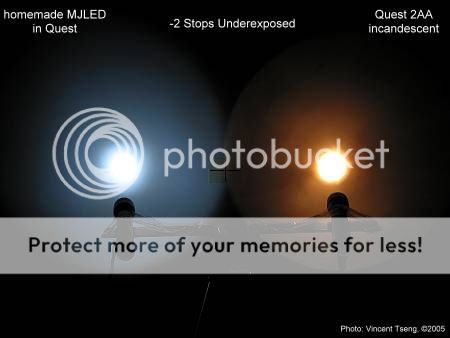

Compared to gen2 MJLED (#2) bought from Sandwich Shoppe -

The homemade MJLED seemed a shade brighter (but see later**) with a cooler bluer tint compared to my gen2 MJLED #2

Compared to gen2 MJLED (#1) bought from Lambda -

now the gen2 MJLED #1 seems a shade brighter - **well it is probably because the AA batteries in the MiniMag body of the MJLED #1 are possibly a bit fresher than those installed for the MJLED #2.

My gen2 MJLED #1 as noted previously has a yellow-green tint in comparison to the gen2 MJLED #2 and this is emphasized even more with the slightly cooler bluer tint of the wwglen homemade MJLED.

Looking at the homemade MJLED closely (see close-up above) indeed the cut-off looks less polished/finished than a "real" MJLED - but the results show that it is every bit as effective - perhaps there is a bit more asymmetry when the beam is defocussed to flood (with doughnut-hole) but I hardly ever use this so it is moot for me - and possibly with more patient centering of the homemade MJLED I may be able to get the symmetry/centering better -

but it really works fine the way it is - with minimal effort in installation...

Many thanks to wwglen for your generosity, and for this excellent LED that seems pretty comparable to my "real" gen2 MJLEDs -

and you know how enthusisatic I was about the MJLEDs.......

[ QUOTE ]

wwglen said:a "Homemade" MJLED. This is a high power 100mA 5mm LED I got from a group buy, ground down using a dremal tool. Looks rough but the three I have are about the same (brightness and beam shape) as the third gen MJLEDs I got.

[/ QUOTE ]

I did the shameless thing and begged wwglen for one of his homemade MJLEDs.

The wwglen home made MJLED arrived in the mail today, many thanks to wwglen for your generosity.

So I cut the legs to about 7/16" from the plastic dome base (just like I did with my previous MJLEDs) and replaced the MJLED in turn with each of my 2 gen2 MJLED MiniMag 2AAs for my comparisons.

Please see this thread -

MJLED drop-in for MiniMag 2AA

wwglen's Homemade MJLED installed -

Compared to gen2 MJLED (#2) bought from Sandwich Shoppe -

The homemade MJLED seemed a shade brighter (but see later**) with a cooler bluer tint compared to my gen2 MJLED #2

Compared to gen2 MJLED (#1) bought from Lambda -

now the gen2 MJLED #1 seems a shade brighter - **well it is probably because the AA batteries in the MiniMag body of the MJLED #1 are possibly a bit fresher than those installed for the MJLED #2.

My gen2 MJLED #1 as noted previously has a yellow-green tint in comparison to the gen2 MJLED #2 and this is emphasized even more with the slightly cooler bluer tint of the wwglen homemade MJLED.

Looking at the homemade MJLED closely (see close-up above) indeed the cut-off looks less polished/finished than a "real" MJLED - but the results show that it is every bit as effective - perhaps there is a bit more asymmetry when the beam is defocussed to flood (with doughnut-hole) but I hardly ever use this so it is moot for me - and possibly with more patient centering of the homemade MJLED I may be able to get the symmetry/centering better -

but it really works fine the way it is - with minimal effort in installation...

Many thanks to wwglen for your generosity, and for this excellent LED that seems pretty comparable to my "real" gen2 MJLEDs -

and you know how enthusisatic I was about the MJLEDs.......