I can see how the circular LED could end up with a lot of waste UNLESS the dies are cut from a rod instead of from a wafer. However, if a wafer is used, a hexagonal die would have comparable optical properties to a circular die, but with zero wasted wafer area.

They would never do that. More cost effective to use large wafers and remove the unwanted portion than to create tiny wafers that would need all new machines to process and then have tiny yields. In fact that is a crazy bad idea. No offense meant. The hexagonal idea? Well sure you could do that. But I believe the processes to do that are covered by patents from another company and wouldn't necessarily be as good optically for certain applications.

CBT-140 don't have white, only RGB - unless I'm missing something?

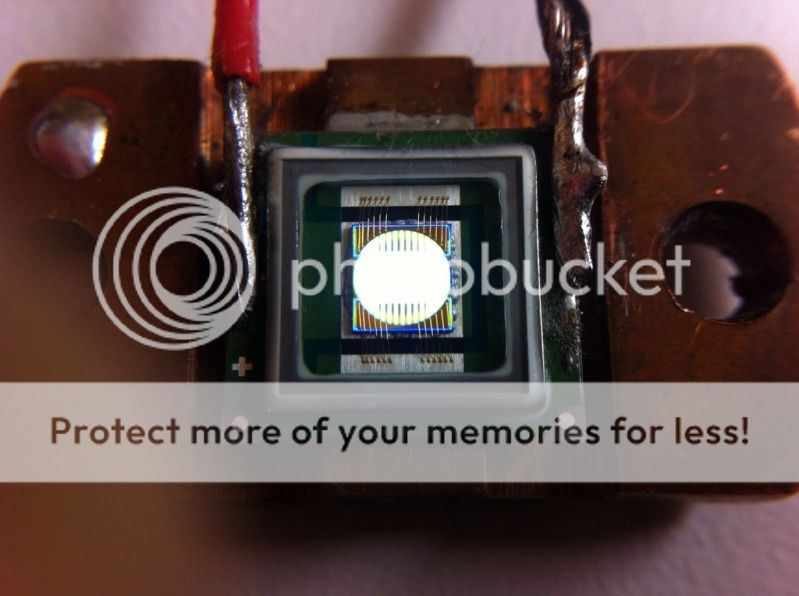

You are thinking of the CBT-40. I said CBT-140. Very different animal. The CBT-140 is to my knowledge the largest monolithic die yet capable of drive current over 27A! Think of it as a grown-up version of the SBT-70.

But no pressure Micheal :naughty:

But no pressure Micheal :naughty: