Still no concensus on this whole blackening thing, huh?

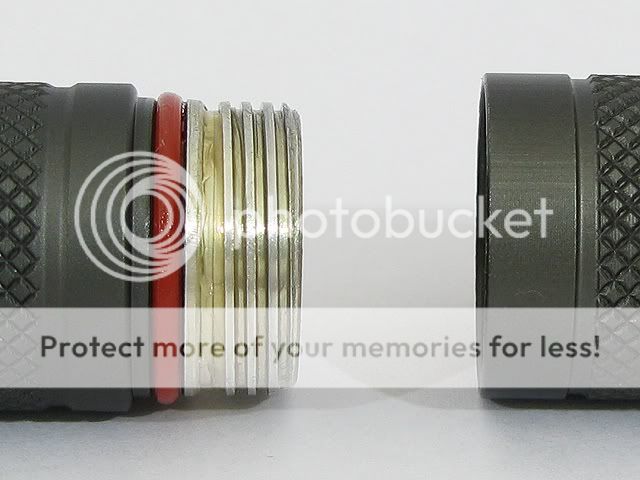

I still strongly feel that the blackening comes from metal being abraded from the threads. I have both Nyogel products that Lighthound currently sells and both will turn black, but

only after extended use. I've never seen any comments from the manufacturer, but if they exist I'd love to see them (oxidation of the lube seems, to me, to be a very unlikely explanation). Anyway, in my experience, if the Nyogel is on a tailcap that doesn't get removed very often, it takes quite a while to turn black. Therefore, it seems reasonable to assume that very small amounts of aluminum are, in fact, contaminating the lube. Also, these lubricants (silicone-based) are typically thickened with amorphous (fumed, spherical morphology) silica (I cannot confirm this for Nyogel as their formulation is proprietary, but I'm certain that this is common practice) which may make the effect more apparent. My

theory (to be proven once I get access to an SEM with EDS) is that the silica particles in the Nyogel (assuming they're in there), by virtue of their hardness and potential to come in direct contact with bare aluminum under significant compressive loads, may acquire an extremely thin coating of aluminum under shear forces generated when the threads are operating, thereby magnifying the color change.

http://en.wikipedia.org/wiki/Silicone_grease

Anyway, I think nanoscale abrasion is perfectly normal for lubricated threads (using

any lube) - there's no such thing as a perfect lubricant - and it doesn't reflect poorly on the quality of the lube. The amount of material being removed from the threads is insignificant and will never be noticable to the user (the threads will always work just fine). I use pure Krytox grease (very expensive as formulated for laboratory glassware - extremely resistant to oxidation, heat, etc) on my Ti McGizmo and the threads still turn black after a week of frequent use.

btw - For titanium in general, my understanding is that PTFE-based products are far superior to anything else. This has been stated in many a lube thread.