wptski

Flashlight Enthusiast

Ray of Light:

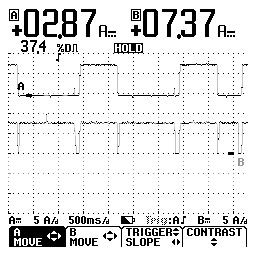

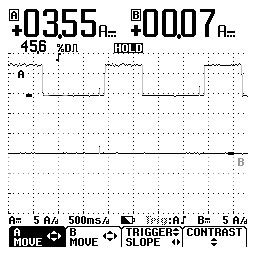

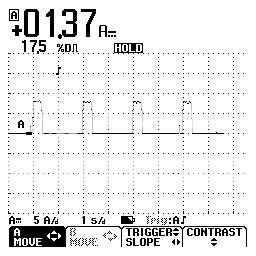

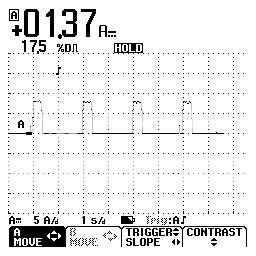

Here's a scope screen capture a short time after the green LED came on but it only lasted a short time at 1.37A and dropped to about 70ma then zero. I waited till the charger's fan turned off which is several minutes and seen nothing! I mention in another thread that I didn't think that this charger had a trickle mode.

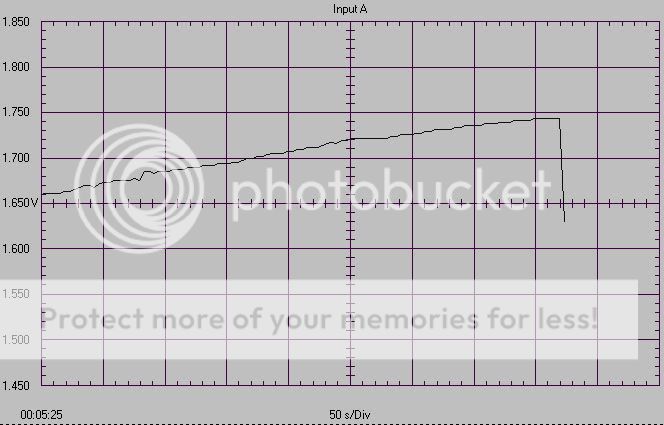

My cells come off the charger at 1.4V or so, maybe it's the cells?

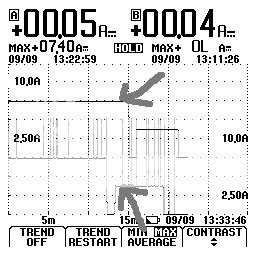

These scope screen captures look pretty good! I could fit three across too!

I could fit three across too!

Here's a scope screen capture a short time after the green LED came on but it only lasted a short time at 1.37A and dropped to about 70ma then zero. I waited till the charger's fan turned off which is several minutes and seen nothing! I mention in another thread that I didn't think that this charger had a trickle mode.

My cells come off the charger at 1.4V or so, maybe it's the cells?

These scope screen captures look pretty good!

Last edited: