old4570

Flashlight Enthusiast

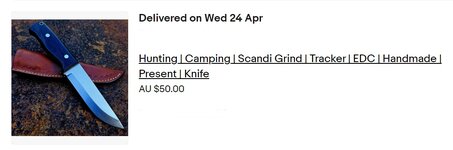

What I got was a locally supplied ( Fee Bay ) Scandi knife . ( OAL 9 inches )

Its not super large , though it is a HULK of steel ! Around 5.8mm thick . Supposedly 1095 Carbon !

My HRC file say's 55HRC - as the file skated and bit ever so slightly the blade steel .

Think MORA on steroids when you see this knife . ( if you see it ) .

The edge failed / rolled at ( started @ 50 slices ) 300 slices . But , a quick wood strop had the edge slicing paper again . I think I paid around 50 bananas for this knife ( Oz bananas ) . And it was re sharpened full scandi . The factory edge was .......................................... Not sure I know where it was ? So I had to put an edge on it myself . 300 slices full scandi is decent / average performance for a bellow average price . Watch the video if you want to know more (?)

Video is uploaded , and VEOH is going to re code it ( not so well ) .

Posted on VEOH

Last edited: