NewBie

*Retired*

Stainess Steel screen looks nice too.

If you are worried about stuff getting out of the case jtice, a simple radio can go a long ways to showing you how bad of a problem you have.

As far as stuff getting into it, except for static, it's pretty much a load of utter bunk.

I have nine motherboards around the house that have now been running for years, that are not in any sort of case at all. Zero problems with stability issues. Nor has static been an issue. You need to blow them off once in a blue moon to remove the dust.

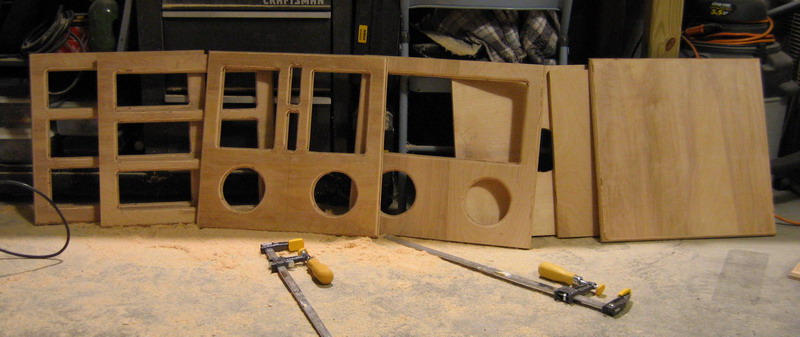

Here is a photo of a few of my herd:

If you are worried about stuff getting out of the case jtice, a simple radio can go a long ways to showing you how bad of a problem you have.

As far as stuff getting into it, except for static, it's pretty much a load of utter bunk.

I have nine motherboards around the house that have now been running for years, that are not in any sort of case at all. Zero problems with stability issues. Nor has static been an issue. You need to blow them off once in a blue moon to remove the dust.

Here is a photo of a few of my herd: