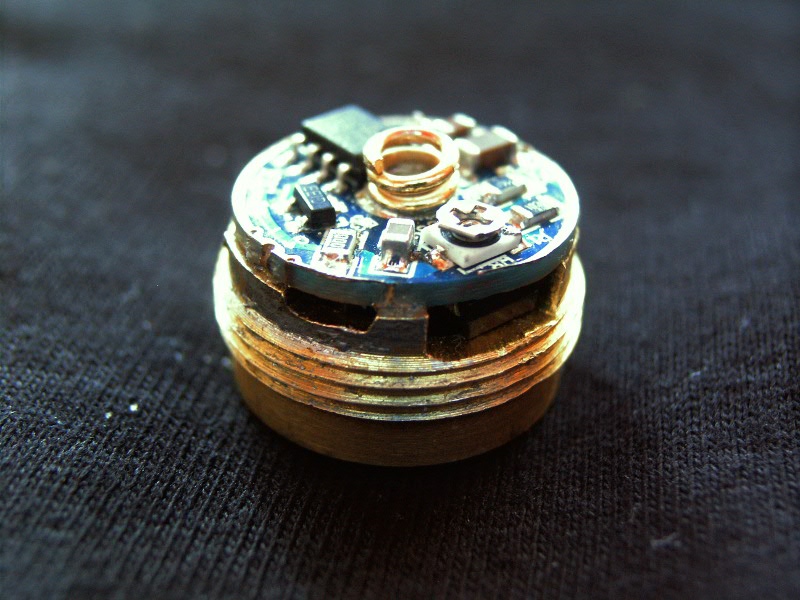

I have a DX UltraFire A10 AA or 14500 flashlight and really like the light. It's a single mode and while very bright on the 14500 battery it does get really hot fast. I would like to replace the board with a 2 or 3 mode board that can still handle the higher voltage of the 14500 battery, but would let me lower the output some. It needs a 14mm to 15mm PCB and they seem much harder to find than a 17mm board. I do not mind paying for a good board.

Any ideas are very welcome, I know you folks have so much knowledge in this area.

Thanks, Louis

Any ideas are very welcome, I know you folks have so much knowledge in this area.

Thanks, Louis

Last edited: