wquiles

Flashaholic

This is the second light for this forum member. The owner wanted something "different" using an MC-E, so here is goes - I hope he will be happy. As with the prior P7 light, the goal was to use the AW "C" LiIon cells the owner has, and to make these lights regulated. This was a more time consuming than the prior P7 light to build, but definitely worth the extra effort.

For reference, these are the prior custom lights that I have built around this outstanding host from Barbolight:

- Regulated Barbolight Bomb-Proof Host with P7, hipCC, and AW C LiIon cells:

http://www.candlepowerforums.com/vb/showthread.php?t=236461

- 3x MC-E:

http://www.candlepowerforums.com/vb/showthread.php?t=232273

- single P7

http://www.candlepowerforums.com/vb/showthread.php?t=222258

- single MC-E:

http://www.candlepowerforums.com/vb/showthread.php?t=226575

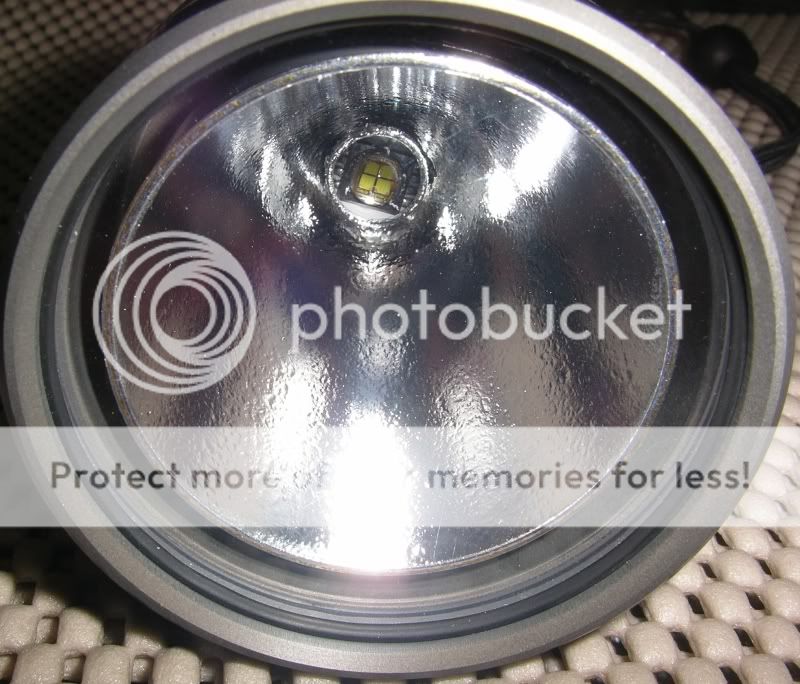

For this light I am using a reflector from DX in Asia designed for the Cree, but with a smaller diameter than the reflector I used in the P7 light:

One of the bared hosts that I got was truly "epoxied" so hard that the normal oven treatment did not work - this is the second host that I have not been able to get opened. So, what I did is that I used this bared host for a project host - and I cut in several key places to allow me "see" inside and test fitting ideas more easily. Here you can see the cut host holding the new Cree reflector:

To make this MC-E version more distinctively "different", I decided to used neutral tint MC-E emiters - as you will see in post #2, the results are very, very nice with this tint:

Since I am staking vertically the emiter and the reflector, I started by measuring the emiter:

The reflector was measured using my "small" height gauge:

Although I consider me a little bit of a hack, not a "true" designer, I do take lots of notes and do a rough paper design (at least an initial one) before getting started, which of course gets modified accordingly as I do the actual build. Here are some of the initial ideas:

For the head, since it has a hole right in the middle (where the MC-E needs to be!), I had to come up with a way to fill that space. Since I had time on my side, I decided to go with a premium "plug" made of pure copper. Here I start making the initial cut (which I will later up open up to about 1" in dia):

I took one of the custom heatsinks/LED driver "housing" and removed the P7 platform (since it will be flat against the bottom of the head):

I then made the ring/spacer that will hold the reflector perfectly centered in the head:

Started work on the positive battery contact:

and here I am driving the hipCC (www.taskled.com):

Like with the P7 light, I am using 10mil thermal tape from 3M to get the back of the hipCC "glued" to the Aluminum cup:

Although all drivers from George are tested, here I am testing it to make sure I did not kill it or wired something wrong:

Here you can see the pure copper insert/plug and the MC-E thermally glued (two-part thermal epoxy) to it. Note that I had to make an extra hole since I made a mistake while on the rotary table:

To give this project a more unique look, I gave the outer ring/spacer a light coat of glow in the dark powder mixed with two-part epoxy:

Using thermal two-part epoxy I glue the driver/cup to the back of the head, using the body of the light to center it while the epoxy dries:

Here is the head, ready to be wired:

Emiter wires soldered:

another quick test to make sure everything works fine:

then make the ground connection with a taped screw, which goes through the head and into the edge of the main tube, for a solid GND connection:

I then apply silicon sealant to the head to seal water (diving rated host deserves nothing less!):

I apply "very" thin Kapton tape to make sure there is no possible short:

Epoxy all wires and holes for extra measure:

Start work on the custom Delrin battery carrier:

Tested a couple of springs:

Made cut for the Al cup which will hold the spring:

made the custom Al cup, which is fitted to the Delrin battery carrier:

Made the internal cut to grab the spring:

and this is how it looks prior to adjusting the length of the spring:

uncompressed:

compressed (I had to trim the spring about 0.120", which then was silver epoxied to the Al cup):

Epoxy the inside of the head to glue the reflector/spacer in place:

and it is almost ready:

I have to install the o-rings and lens, and it is done

Will

For reference, these are the prior custom lights that I have built around this outstanding host from Barbolight:

- Regulated Barbolight Bomb-Proof Host with P7, hipCC, and AW C LiIon cells:

http://www.candlepowerforums.com/vb/showthread.php?t=236461

- 3x MC-E:

http://www.candlepowerforums.com/vb/showthread.php?t=232273

- single P7

http://www.candlepowerforums.com/vb/showthread.php?t=222258

- single MC-E:

http://www.candlepowerforums.com/vb/showthread.php?t=226575

For this light I am using a reflector from DX in Asia designed for the Cree, but with a smaller diameter than the reflector I used in the P7 light:

One of the bared hosts that I got was truly "epoxied" so hard that the normal oven treatment did not work - this is the second host that I have not been able to get opened. So, what I did is that I used this bared host for a project host - and I cut in several key places to allow me "see" inside and test fitting ideas more easily. Here you can see the cut host holding the new Cree reflector:

To make this MC-E version more distinctively "different", I decided to used neutral tint MC-E emiters - as you will see in post #2, the results are very, very nice with this tint:

Since I am staking vertically the emiter and the reflector, I started by measuring the emiter:

The reflector was measured using my "small" height gauge:

Although I consider me a little bit of a hack, not a "true" designer, I do take lots of notes and do a rough paper design (at least an initial one) before getting started, which of course gets modified accordingly as I do the actual build. Here are some of the initial ideas:

For the head, since it has a hole right in the middle (where the MC-E needs to be!), I had to come up with a way to fill that space. Since I had time on my side, I decided to go with a premium "plug" made of pure copper. Here I start making the initial cut (which I will later up open up to about 1" in dia):

I took one of the custom heatsinks/LED driver "housing" and removed the P7 platform (since it will be flat against the bottom of the head):

I then made the ring/spacer that will hold the reflector perfectly centered in the head:

Started work on the positive battery contact:

and here I am driving the hipCC (www.taskled.com):

Like with the P7 light, I am using 10mil thermal tape from 3M to get the back of the hipCC "glued" to the Aluminum cup:

Although all drivers from George are tested, here I am testing it to make sure I did not kill it or wired something wrong:

Here you can see the pure copper insert/plug and the MC-E thermally glued (two-part thermal epoxy) to it. Note that I had to make an extra hole since I made a mistake while on the rotary table:

To give this project a more unique look, I gave the outer ring/spacer a light coat of glow in the dark powder mixed with two-part epoxy:

Using thermal two-part epoxy I glue the driver/cup to the back of the head, using the body of the light to center it while the epoxy dries:

Here is the head, ready to be wired:

Emiter wires soldered:

another quick test to make sure everything works fine:

then make the ground connection with a taped screw, which goes through the head and into the edge of the main tube, for a solid GND connection:

I then apply silicon sealant to the head to seal water (diving rated host deserves nothing less!):

I apply "very" thin Kapton tape to make sure there is no possible short:

Epoxy all wires and holes for extra measure:

Start work on the custom Delrin battery carrier:

Tested a couple of springs:

Made cut for the Al cup which will hold the spring:

made the custom Al cup, which is fitted to the Delrin battery carrier:

Made the internal cut to grab the spring:

and this is how it looks prior to adjusting the length of the spring:

uncompressed:

compressed (I had to trim the spring about 0.120", which then was silver epoxied to the Al cup):

Epoxy the inside of the head to glue the reflector/spacer in place:

and it is almost ready:

I have to install the o-rings and lens, and it is done

Will