Well, I figured out the problem with D3 - I mis-measured it's Vf. After hooking it up to the fancy power supply at the local hackerspace this evening I found that it didn't start passing substantial current until 1.9 or 2.0V.

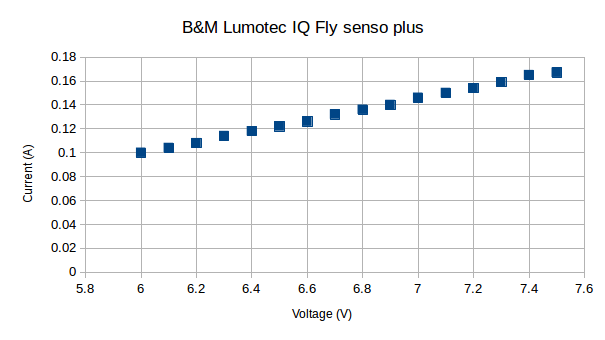

I also did a quick voltage-current graph for the B&M Lumotec IQ Fly Senso Plus headlight I'm using, driving it with a DC power supply:

I also put the voltmeter on it while riding this evening and, while I could barely read the meter (it gets dark so early!), it looked like it was somewhere around 7V - consistent with the voltage I was seeing when running it with the taillight. Unless the light responds very differently to AC, that means it only needs a little over 100mA. I'm not clear how that works, given the dynamo is supposed to put out around 500mA. I'm not quite sure what that means for the taillight I'm working on, either.

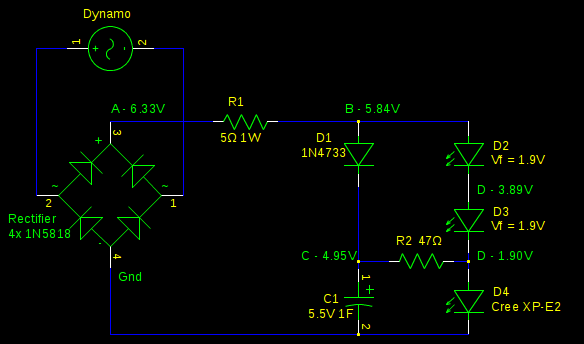

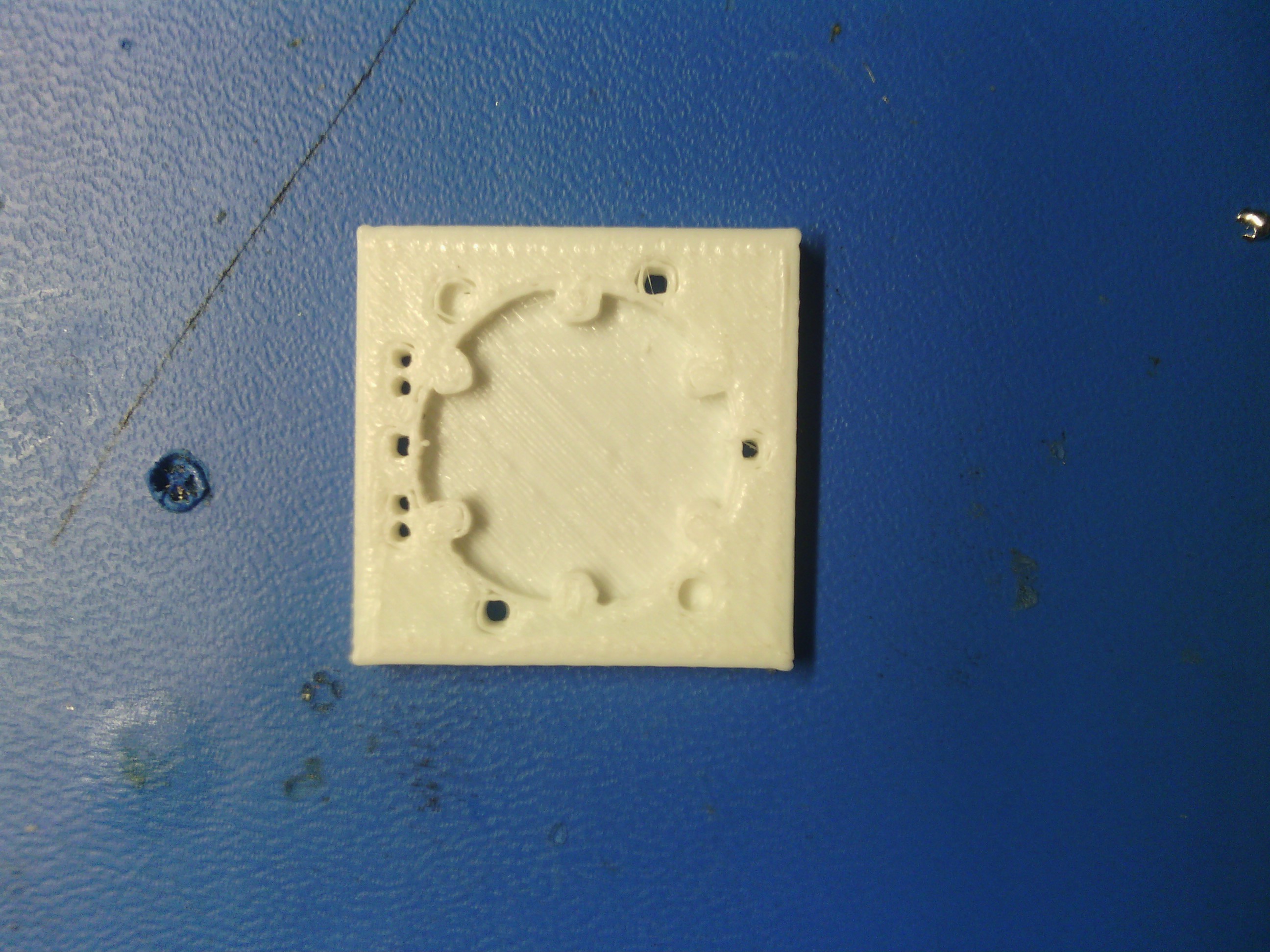

Speaking of the taillight, after a bit of tinkering with both lights hooked up to the fancy power supply I made a few changes. I'm going to hook the light up and test it out on the way home.

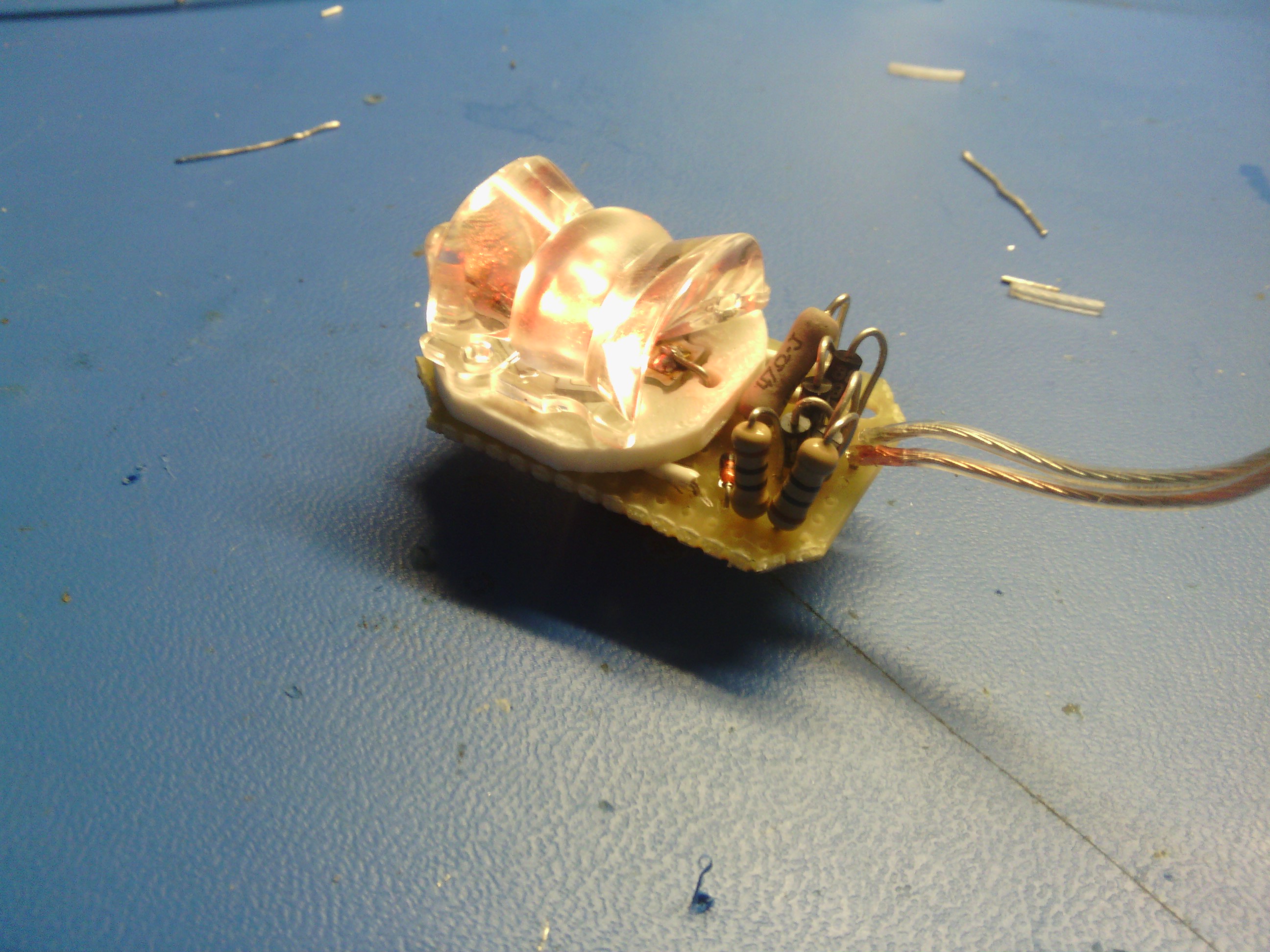

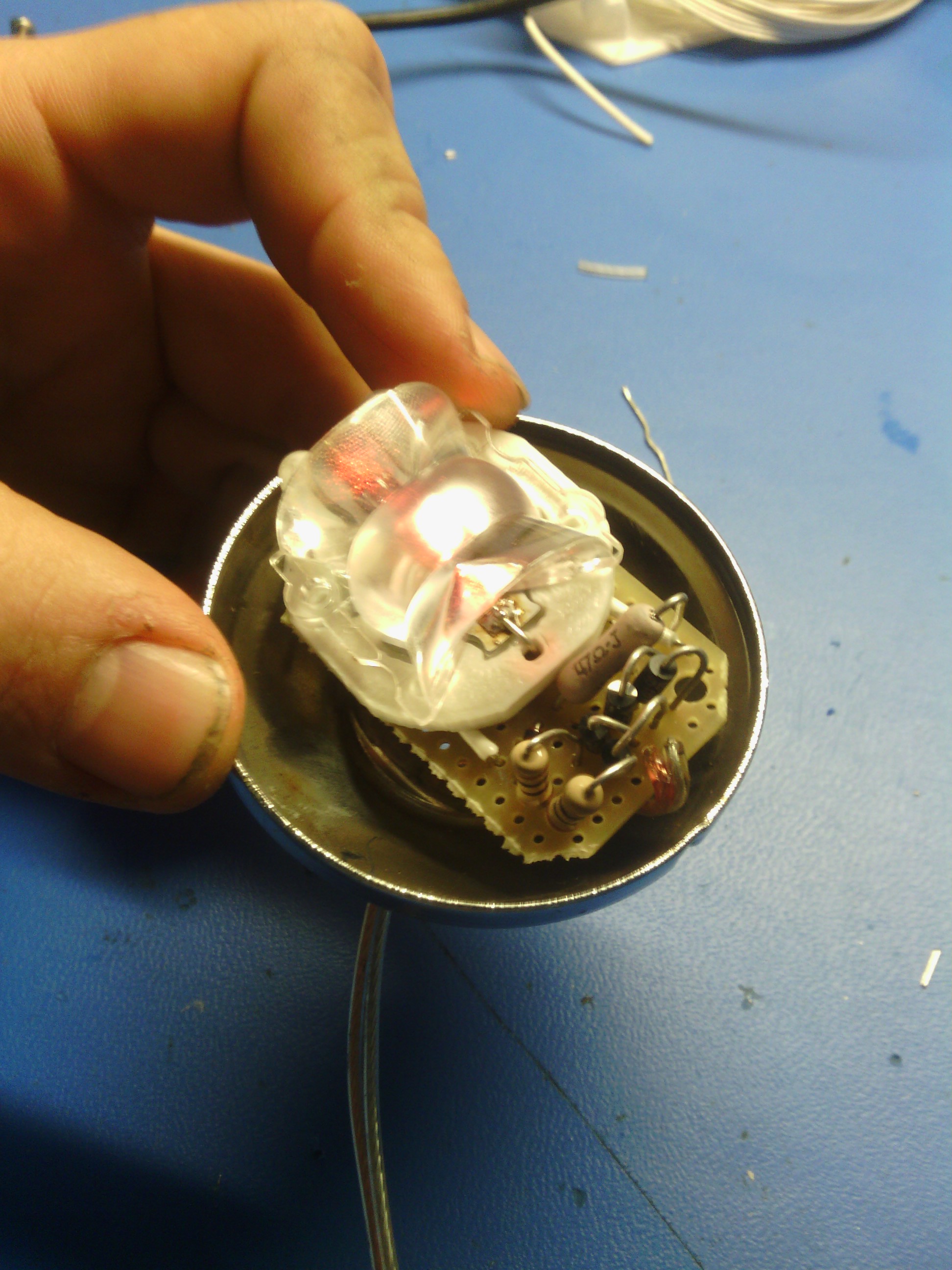

Savvas - the only powerLED is the one across the capacitor. I haven't noticed much dimming of the headlight, and given the chart above I doubt I ever will - this headlight seems to run at surprisingly low power. I wanted to use the XP-E2 so I could put the LEDiL "Flare" optic on it, which I quite like, but it doesn't last very long as a standlight, so I'm thinking about going back to the basic 5mm LEDs. I'd love to do some serious testing with the dynamo as a power source, but I haven't yet broken down and built a rig to drive the wheel while in a stand, so the only way I can do it is with the voltmeter on my handlebars, taking quick readings as I ride.

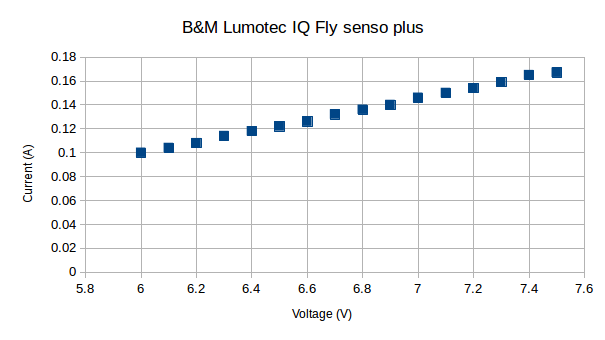

I also did a quick voltage-current graph for the B&M Lumotec IQ Fly Senso Plus headlight I'm using, driving it with a DC power supply:

I also put the voltmeter on it while riding this evening and, while I could barely read the meter (it gets dark so early!), it looked like it was somewhere around 7V - consistent with the voltage I was seeing when running it with the taillight. Unless the light responds very differently to AC, that means it only needs a little over 100mA. I'm not clear how that works, given the dynamo is supposed to put out around 500mA. I'm not quite sure what that means for the taillight I'm working on, either.

Speaking of the taillight, after a bit of tinkering with both lights hooked up to the fancy power supply I made a few changes. I'm going to hook the light up and test it out on the way home.

Savvas - the only powerLED is the one across the capacitor. I haven't noticed much dimming of the headlight, and given the chart above I doubt I ever will - this headlight seems to run at surprisingly low power. I wanted to use the XP-E2 so I could put the LEDiL "Flare" optic on it, which I quite like, but it doesn't last very long as a standlight, so I'm thinking about going back to the basic 5mm LEDs. I'd love to do some serious testing with the dynamo as a power source, but I haven't yet broken down and built a rig to drive the wheel while in a stand, so the only way I can do it is with the voltmeter on my handlebars, taking quick readings as I ride.