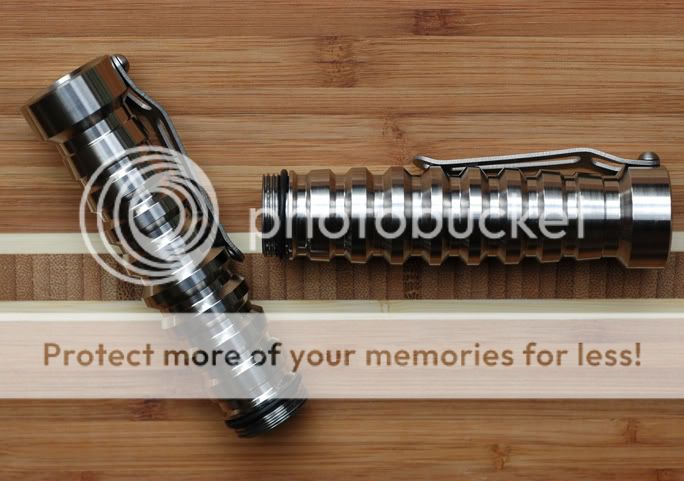

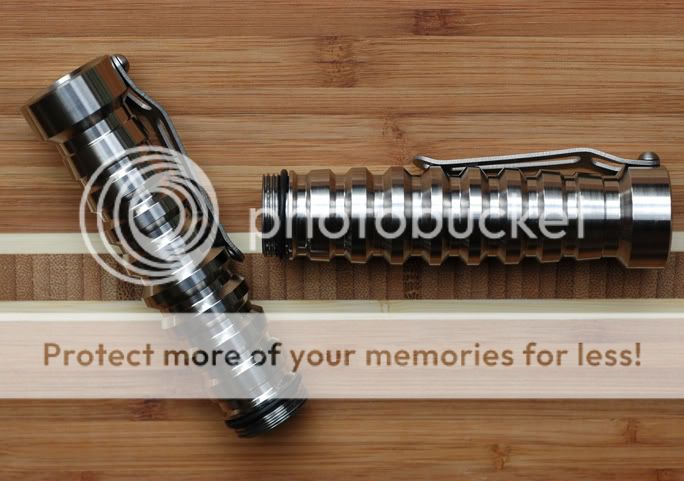

Thanks for the continued input, but to clarify my original request: the body in question is not E-series, but McLuxIII with threads internal to the body.

I caught this thread the other day and realized that you were not seeking to open the bore of an E-series which would be a problem because of the O-ring groove (.750" OD at root) VS the ID of the tube which is nominally .675" leaving you with a wall thickness of .0375" before you remove any material.

Since you want to bore out the Cx2 pak, your minimum wall thickness will be at the root of the grooves on the body itself which is about .780" OD so at present, you have a wall thickness of .0525". You can determine the resulting wall thickness after the boring out and decide if this is acceptable to you. It is all straight forward to my way of thinking and since I have no intention of offering or attempting such a mod, I refrained from posting. Had you been wanting to open the bore on the 2x123 McClickie pak, I would have posted in a cautionary, "Don't Do It" and why. Your "less than 1/16" material removal" was not specific enough for me to make a judgment call but now that I am posting, I would advise that it would be best if it is well bellow 1/16". If you remove .0625" of material, that will leave you with minimum wall thickness of ~.022" which is viable considering the tube is Ti but the light will appear to be much more robust than it actually is. The part could also act up on the machinist in the process of removing this material!

Don apparently doesn't keep very good records. In the past when I've asked technical questions, he has been quite vague with the details.

I don't doubt that I can be vague on details depending on what the question was and how old it was in reference to. I have hundreds of drawings going back many years and my memory is the pits. Without knowing the reference, I won't attempt a guess at what this is or was about. I may well have been vague for other reasons as well. :shrug:

As you and others have identified, the profile of the pak has a curved outer form and each rib is different in OD. I would imagine that a pressed on sleeve in say delrin that had an OD to match that of the tail OD might give you a good a reasonable grab on the pak.

Last night I saw your request for

..exact dimensional drawing of the McLuxIII Ti Cx2 Clicky Pak

I figured I would sleep on a response as my initial response was one of surprise and incredulity. I don't even have an exact dimensioned drawing on this part because I was able to supply it in an IGIS file to the machine shop and they pulled what dimensions they wished from the solids file. Now I could take an hour and generate a dimensioned drawing and convert it to PDF but frankly, why should I?

It has been my experience that if I plan to modify a specific part then I use that part to provide me the geometry I am working with; especially if I plan to push it to its limits. Because there are tolerances involved in the general case, I am more interested in the actual dimensions of that which I am modifying.

Years back, I decided to base much of my design on the "E" series of SureFire. I gleaned from PK that he had no real problem with this. I never asked him for SF drawings, critical or target dimensions with tolerances or any other questions regarding their design. I figured if I wanted to use their dimensions that it was up to me to glean them from parts on hand. :shrug:

I have seen some of my stuff reverse engineered and in some cases, I could care less and in others, I feel that the work was a bit too close to my home and I won't make a stink about it but I certainly didn't appreciate it. At any rate, I have no interest in making it easier for someone by providing exact dimensioned drawings!

To be clear here, I see no problem or issue from my stand point in you seeking to modify your battery pak to be host to a battery it was not intended for. To my perception, the critical dimensions are existing bore and intended bore and how they relate to the material at hand. In addition you need to deal with a part that does not have a consistant OD across its length.

Had I intended for this pak to host a larger diameter battery, I would have designed it that way and not gone as deep with the rib groves.

You want to modify it which is your call and I hope my comments specific to this modification have been of some assistance. With a pair of digital callipers, I believe you could have determined the needed information in a matter of moments, yourself. I don't doubt there is talent here and some machinists who can accomplish what you seek. I don't see this as a trivial modification but that is based on my personal experience; as limited as it is.