gt40

Enlightened

Since getting the jet 13x40 lathe and a mini mill, I am finally starting to try to use it to make some stuff. The learning to lathe thing is no joke. This thread is to document my progress on my first light from scratch.

Basics:

Led: sst90 top bin

Battery: (1) Battery Space 26650 battery (4000mah/10 amp)

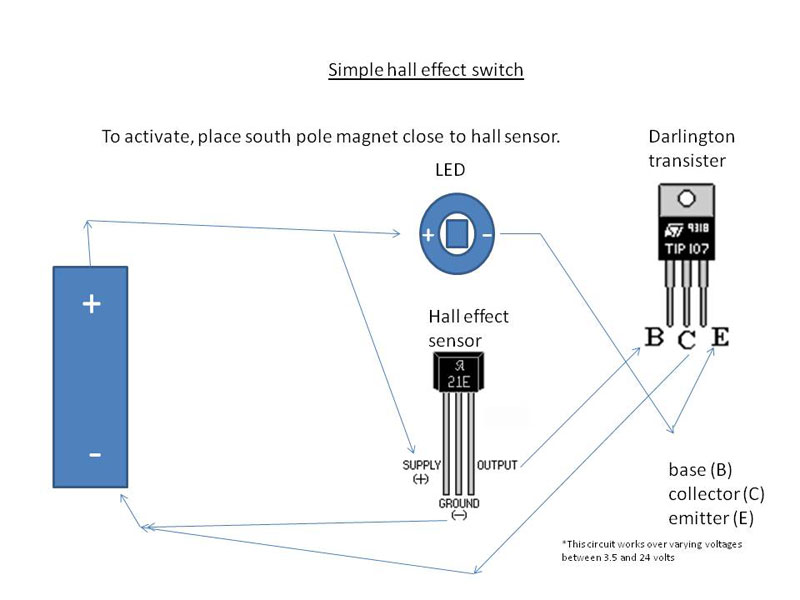

Switch: mosfet with hall effect sensor and a magnet embedded in a ring on the outside of the body i.e. when you turn the ring so the south pole of the magnet is over the hall effect sensor, it turns on.

Driver: It is direct drive

Optics: Aspherical 32mm lens from surplus shed

Heatsink: solid copper slug 1 1/2" long.

Additional cooling: The body will be substantially grooved and solid t6 aluminum to act as a giant heat sink in addition.

This light will be completely water proof and divable with o rings throughout. I will probably use it primarily as a super bright fairly compact light for walking my 3 dogs. I wanted something almost as bright as my mag 3c sst90 aspheric build in as compact as possible.

The light is being built also as an exercise to build skills with the lathe and mill as I am a total newbie with a big lathe

Here are some pics of the raw build so far:

full light pic 1:

from the top:

I am going to taper the head and groove it + still have to machine the "donut switch" to fit on the outside of the head.

Here is the donut I have to machine:

It will be machined to just slightly larger the tube and be grooved or knurled and it will sit in a groove on the tube with o rings to make it rotate smoothly.

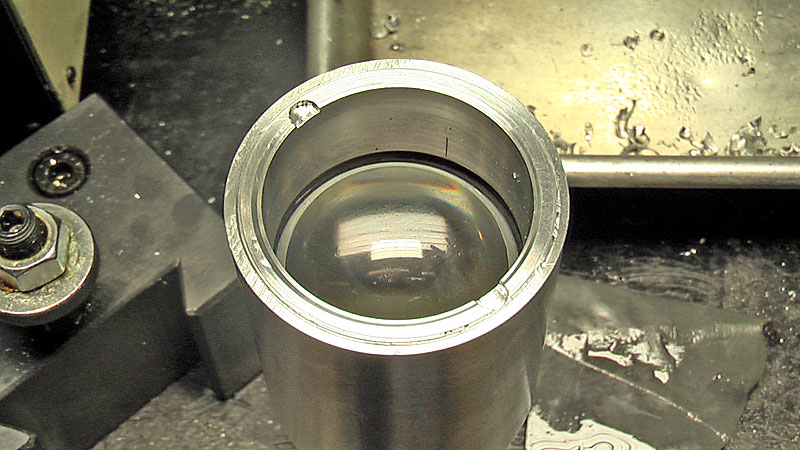

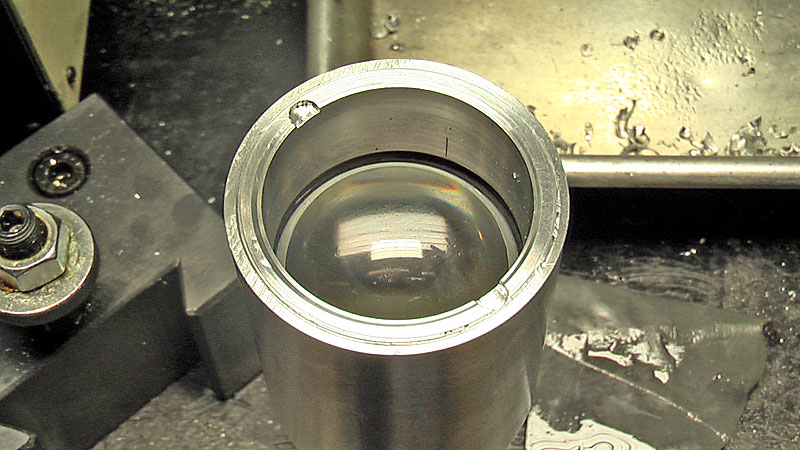

Here is a close up of the aspheric I got from surplus shed. It is supported by an o ring on the bottom which is in a groove I machined in the ledge on the inside of the head:

Here is a shot of the bottom o ring:

There is another o ring on top of the lens so it is supported on both the top and bottom by them to help provide some shock resistance as well as hopefully water and pressure proofing.

The lens is held in place by a threaded sleeve. I cut a couple of notches in the top and made a temp tool to allow it to be tightened. I will machine the top of the light better for the finished light:

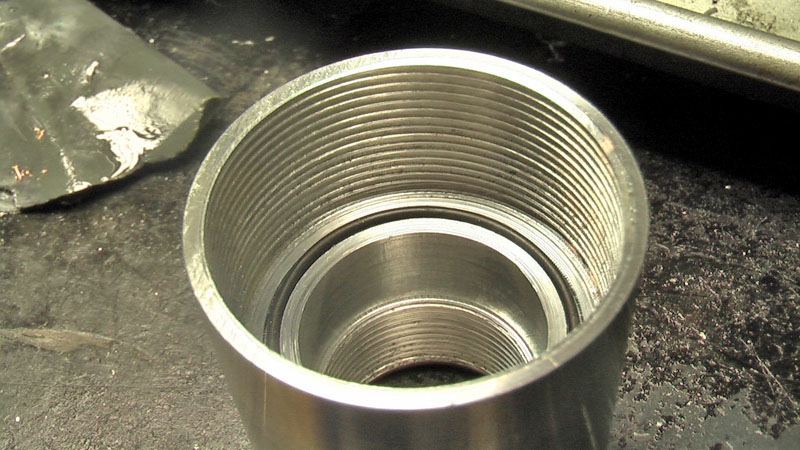

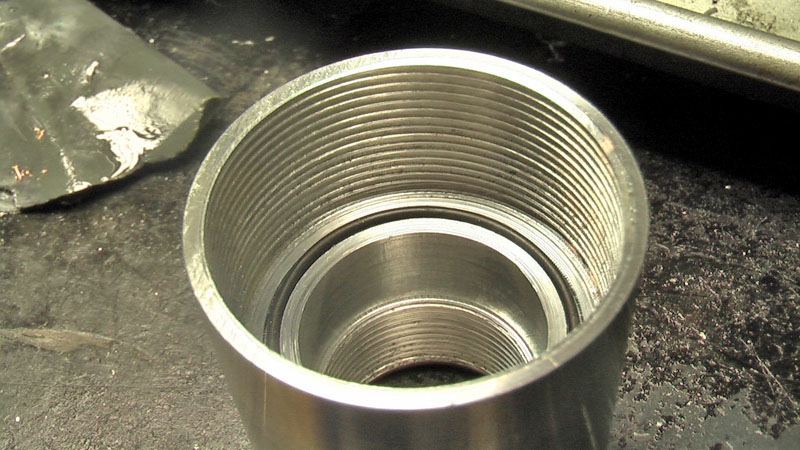

Here is a shot of the bottom of the head showing the threading. Everything is 16 tpi. Learning to thread has been the biggest challenge so far, and I am still learning but everything seems to fit well without slop or binding:

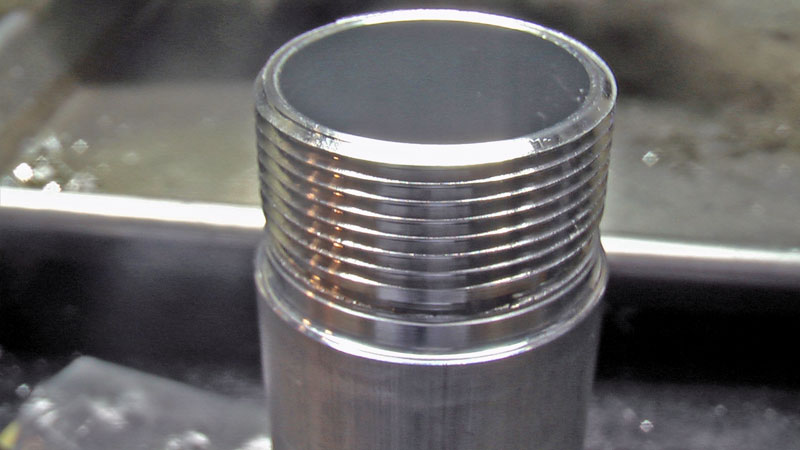

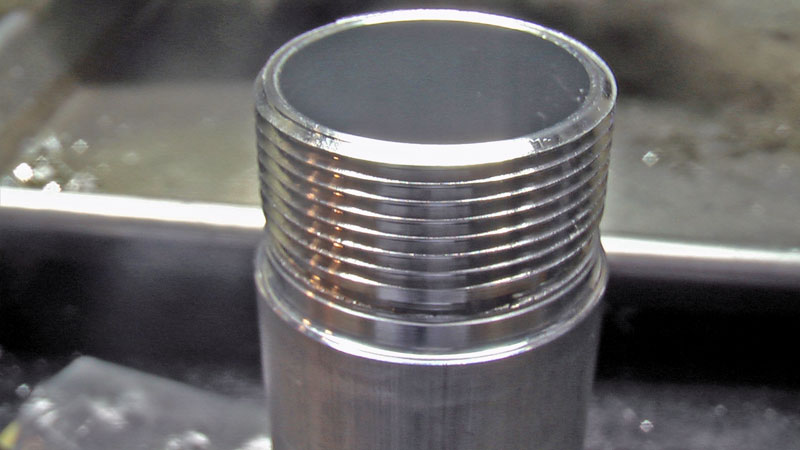

Here is a shot of the threads on the tube. I am still learning here:

I will post more after I do some more machining and make the switch and heatsink.

I have access to anodizing cheap from the shop that works on my race car so the finished light will be anodized after it is finally finished.

Basics:

Led: sst90 top bin

Battery: (1) Battery Space 26650 battery (4000mah/10 amp)

Switch: mosfet with hall effect sensor and a magnet embedded in a ring on the outside of the body i.e. when you turn the ring so the south pole of the magnet is over the hall effect sensor, it turns on.

Driver: It is direct drive

Optics: Aspherical 32mm lens from surplus shed

Heatsink: solid copper slug 1 1/2" long.

Additional cooling: The body will be substantially grooved and solid t6 aluminum to act as a giant heat sink in addition.

This light will be completely water proof and divable with o rings throughout. I will probably use it primarily as a super bright fairly compact light for walking my 3 dogs. I wanted something almost as bright as my mag 3c sst90 aspheric build in as compact as possible.

The light is being built also as an exercise to build skills with the lathe and mill as I am a total newbie with a big lathe

Here are some pics of the raw build so far:

full light pic 1:

from the top:

I am going to taper the head and groove it + still have to machine the "donut switch" to fit on the outside of the head.

Here is the donut I have to machine:

It will be machined to just slightly larger the tube and be grooved or knurled and it will sit in a groove on the tube with o rings to make it rotate smoothly.

Here is a close up of the aspheric I got from surplus shed. It is supported by an o ring on the bottom which is in a groove I machined in the ledge on the inside of the head:

Here is a shot of the bottom o ring:

There is another o ring on top of the lens so it is supported on both the top and bottom by them to help provide some shock resistance as well as hopefully water and pressure proofing.

The lens is held in place by a threaded sleeve. I cut a couple of notches in the top and made a temp tool to allow it to be tightened. I will machine the top of the light better for the finished light:

Here is a shot of the bottom of the head showing the threading. Everything is 16 tpi. Learning to thread has been the biggest challenge so far, and I am still learning but everything seems to fit well without slop or binding:

Here is a shot of the threads on the tube. I am still learning here:

I will post more after I do some more machining and make the switch and heatsink.

I have access to anodizing cheap from the shop that works on my race car so the finished light will be anodized after it is finally finished.

Last edited: