There are many cool things going on here, keep it up. This is a fun thread and it is fun seeing you create new things as a means to another end, such as the crane. The Tesla coil is quite impressive and I am still trying to get a grasp on some of his work and theories. It is cool to see that arc lit up without you having the wires hooked up to anything!

I apologize, but one of my photo hosts has unreliable and unstable links, (Facebook based), and this caused a large amount of my photos to vanish over he last few days. Apologize, but with all the photos I posted I'm not able to update all them do to a variety reasons, mostly time.

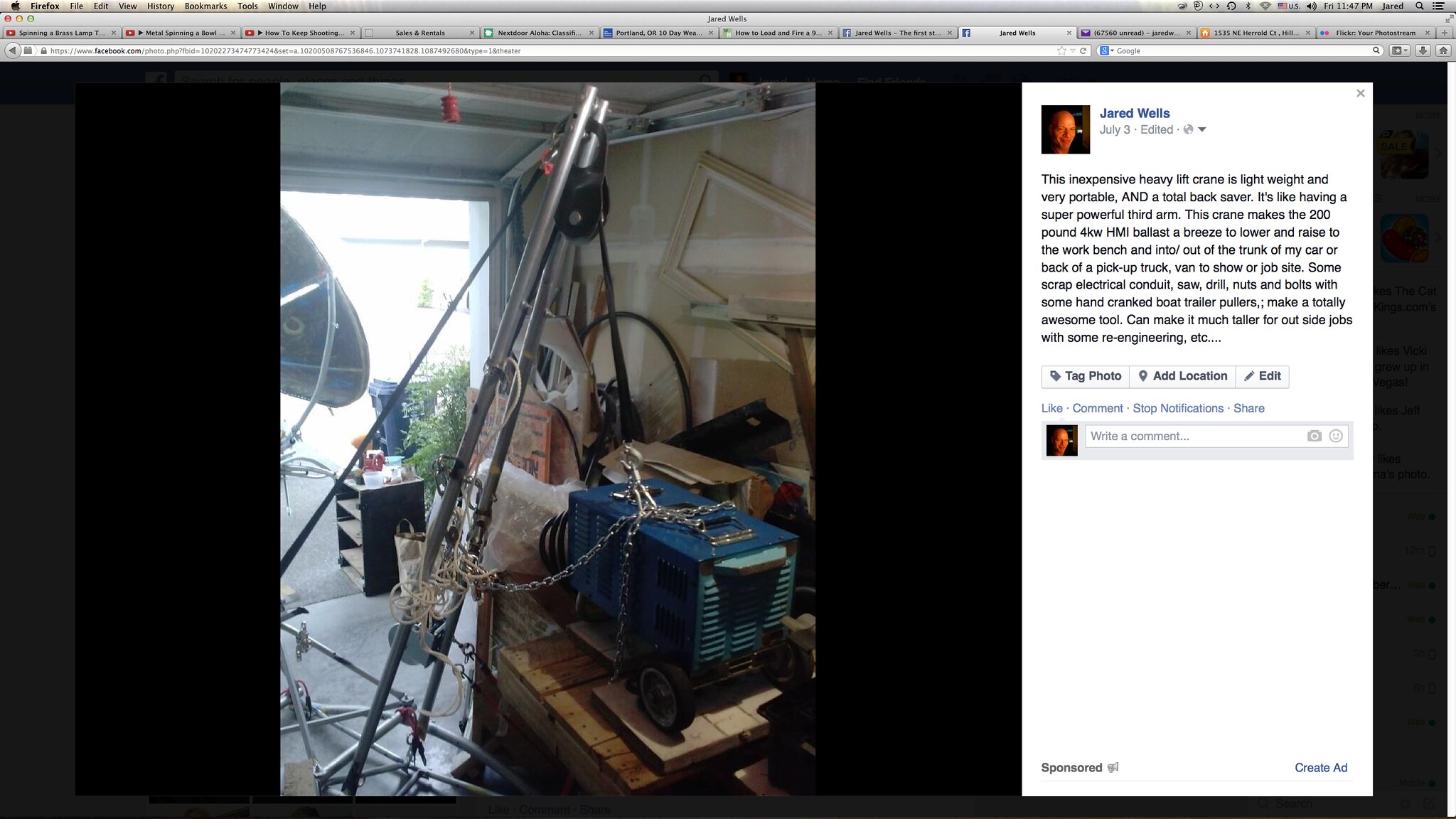

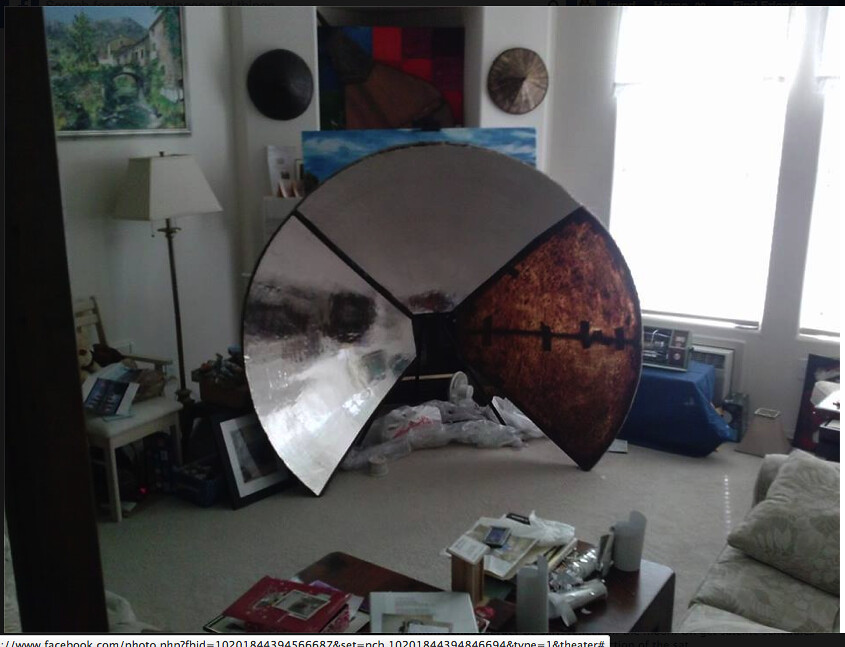

(Sneak Preview) Here is a quick look at the Searchlight when half finished, using only a 100watt HID bulb. Eventually I did Upgrade to a 1200 watt HMI with the help of the IgnITEor.

Thanks. It's a lot of fun and cool to see the results I can get now that seemed impossible years ago.:naughty:

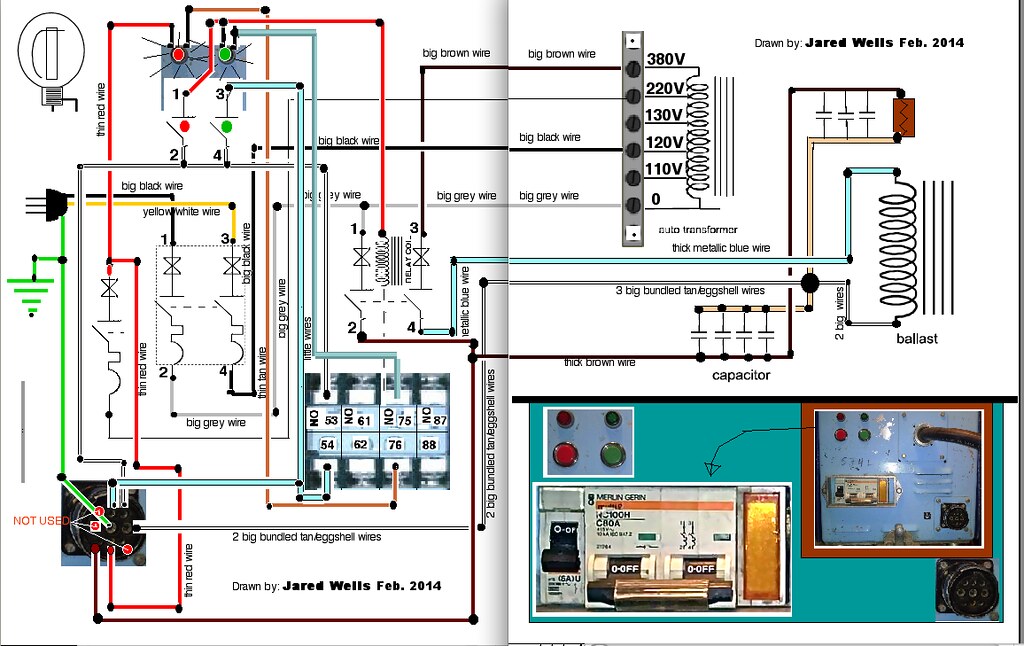

The ignition of HMI bulbs with the a Tesla Coil routine is my temporary remedy for item that's turning out to be hard to locate the exact type and so far the ball park figures look expensive. So until I can afford a real ignitor, Tesla is it..!. Also the Tesla Coil seems to be somewhat friendly to the bulb and allows for the hot re-strike feature of the bulb to be a real possibility with this equipment.

Other benefits of Tesla for now, because of it's 250,000 volts of several megahertz resonating tuned frequency mixed with 300 hertz pulsating signal giving a proper ignition and an occasional manually induced 'cleaning and re-ignition' sequence, (as the electronic ones do), without extinguishing the bulb, just by adding the high voltage while the bulb stays lit for straggling salts that can sit idle)', as per manufacturer recommendations. The Operating Manual is quite long on these bulbs, with lots of little suggestions, but all this is to help prolong the life of the bulb, or at least have better performance for the normal operating lifetime range.

Beginning to experiment with using the Tesla Coil myself and then looked it up online to verify feasibility, and saw a kid demonstrating it on his modern pulse 'grow lights' wired to an old school magnetic ballast with no high voltage capabilities just by placing the Tesla Coil with in five feet or so. I watched a British man working with the 24,000 watt HMI bulb I someday want to lamp this searchlight with so it will be the Brightest without a doubt..,(24kw bulbs are currently used in lights that do not make for a narrow beam. Even my less focused searchlights produce a better beam than those Hollywood type lights.

When using the Tesla Coil, often fluorescent bulbs light up from as far as ten feet. Some day I'd like to build it to better dimensions and get much larger results, but for now it does the job of a little Tesla.

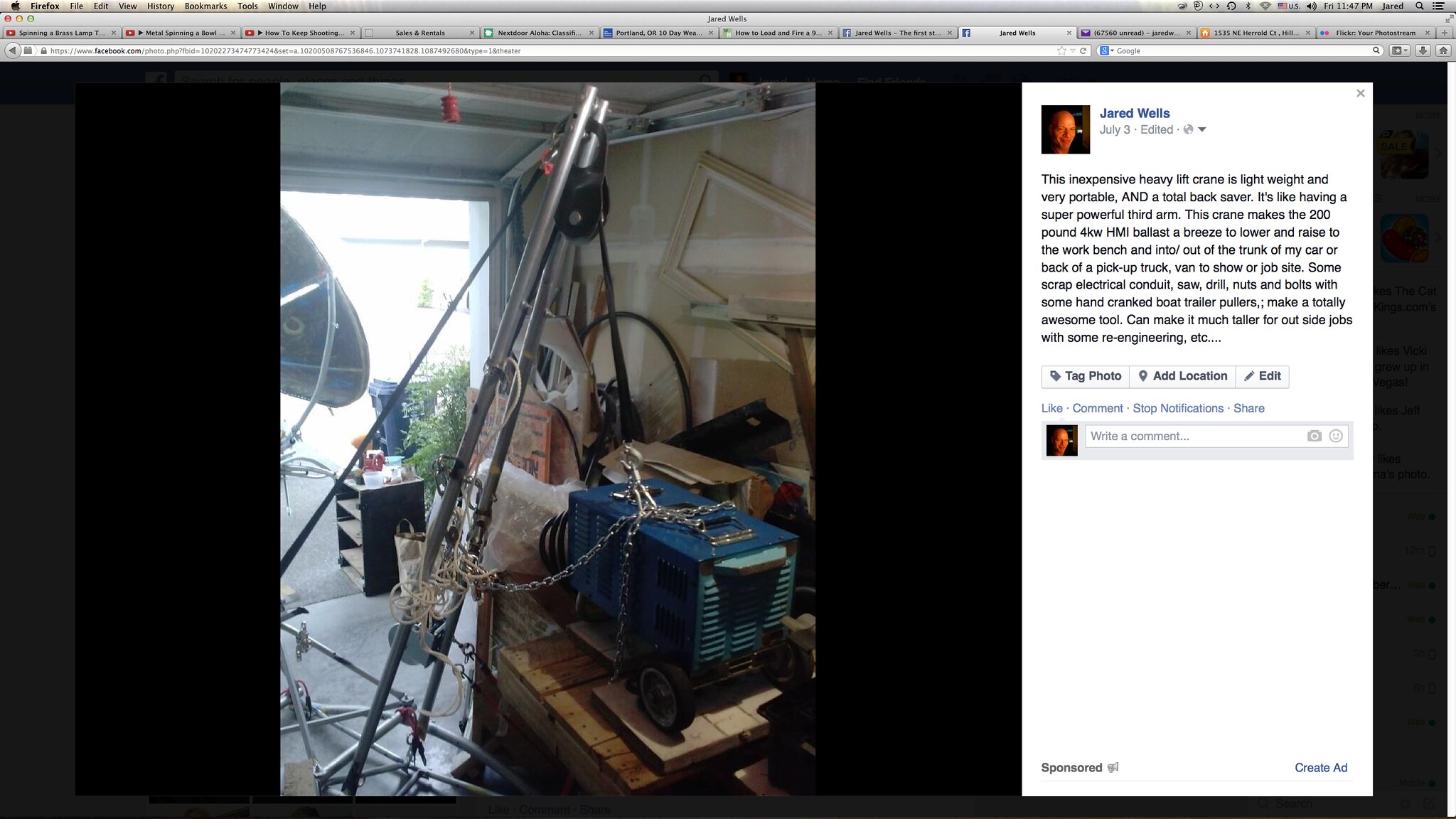

For many things I do, such as the crane, I take quick looks at ancient methods using hand tools to build large, impressive items. It may sound odd going as far back as some original theories, then trace the improvements made over time and eventually make my searchlight(s) or what ever else, from the best and most feasible options, often with my own improvements, making, I hope a remarkable and fun filled and even useful product, perhaps out the loading doors, someday...in theory.

I hope you and everyone else who reads this at the very least finds this an inspiring motivational piece that perhaps even gets someone to go out and do something maybe not even related, but good.:twothumbs