There are different reasons for potting and differing materials for each application. Sometimes there are multiple needs.

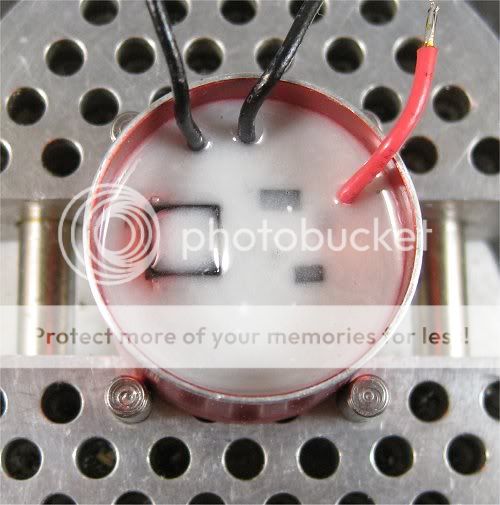

Keep in mind, most potting compounds are thermal insulators. Their primary use is for vibration/impact abatement or hermetic sealing. In the one photo above it appears that the potting is being used structurally. If the primary goal would be as a component adhesive I would suggest there are better approaches. That is, unless there is absolutely no reason ever you need to access the componentry.

If your goal is thermal management, I would suggest examining your approach. Many drivers have individual components projecting at different heights from their boards. If your goal is to use a potting compound to heat sink them all in one shot you are likely doing more detriment than good.

Thermally conductive potting compounds are much better at moving heat than ordinary potting compounds. But that's a statement that requires some context. And that requires understanding how heat moves. There are two basic thermal paths in the devices we're discussing- conductance and emittance. Conductance is the energy of excited electrons moving through a mass. Emittance is that energy radiating from that mass as electromagnetic energy- radiant heat. An un-potted driver is relying on emittance to dissipate heat. That might work to a certain degree if the components were exposed to a steady flow of cooling air, but that doesn't exist inside a flashlight. So we need something that's efficiently conductive to get that heat to a point where it can be emitted. As you can imagine, emittance is significantly less efficient than conductance.

All materials conduct heat at varying rates. That transfer is expressed in how many watts of energy are transferred for a given area. You will see this commonly stated at watts per square meter in degrees Kelvin (W/m K). Copper conducts at about 400 W/m K, aluminum at about 200. Arctic Silver 5 conducts at about 10. There's simply no substitute for how heat energy transfers via an atomic bond. If you took two blocks of copper, polished them to a sub-micron finish and pressed the two together with a binder of micron-sized copper powder in between, they won't conduct the same as a solid block. But there is a way to minimize the effect.

Thermal conductance exists in two forms- in-plane and through-plane. Without getting too deep into this, in-plane is substantially more efficient. This is the very reason every driver manufacturer and every seller of thermal compounds instructs to use the absolute thinnest amount of product for affixing or sinking. Even an extra thousandth or two of thickness has a substantial impact upon performance. The reason for this is that is that the closer two surfaces are, the less through-plane effect they are subjected to. Imagine a highly excited electron moving rapidly. That electron is looking to give that energy to a molecule that has less energy. Since they're atomically bonded to the adjoining molecules, it's an efficient process. When you expend that energy into a material that conducts at a slower rate, the transfer slows to the maximum that second material is capable of conducting at. If you can minimize that material's thickness between two highly conductive materials, the kinetic energy of those excited molecules can "jump the gap", so to speak. The thinner the gap, the more kinetic energy is transferred. This effect diminishes logarithmically as thickness increases. In a very short thickness, the effect is lost and now you're conducting at the rate that material is capable of. Really good thermal potting compounds conduct at about 2 W/m K.

If you're looking to control heat in a driver, the absolute best way to do that is to sink each heat-sensitive component individually. I have a cheap driver I'm working with now. The coil is 0.080" taller than the diode and 0.100 taller than the IC. All it takes is a 1" piece of 1/4" x 1/8" copper square cleanly filed to fit each step. With this filler bonded to the two components, the driver now has a three-point contact with the heat sink. When making heat sinks, there's no such thing as too smooth. I work the surfaces on a glass sheet moving from 400 grit down to 2000. It makes a difference.