In one project we used some type of HP LED as a liquid nitrogen (LN) overflow detector. The LED would get VERY BRIGHT and the current would go down when LN was present, so the LED efficiency appeared to be getting higher. It was an internally current limited LED (and there was also a resistor in series), so there could have been something going on with the current limiting components also. It was good at detecting the cooling capacity of liquid LN, not just the temperature since the gas or gas/liquid mix passing by was basically all at the same 80K temperature anyway. But the cooling capacity of the flow increased dramatically when the liquid content was significant and the LED responded to that. This detector was used to tell when the automated dewar filling cycle was complete.

You may have even seen this system briefly in the Hulk movie of several years ago, as this was the Gammasphere detector that they filmed. They called it a Gamma ray source, actually it is a detector. Each of the more than 100 detectors had a large LN cooled vacuum insulated Germanium crystal and its own dewar, all of which had to be filled several times per day.

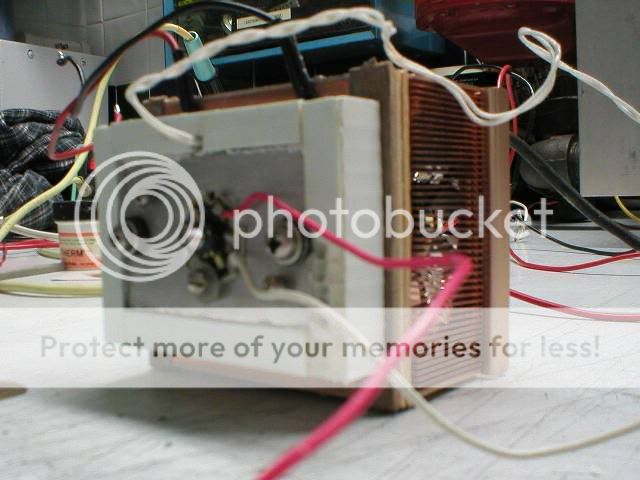

I would think a copper heat transfer bar with LN on the other end would provide pretty good cooling. That is the way the crystals were cooled, the LN did not touch the crystal. There was a heat transfer finger.

Dry Ice is readily available these days at most grocery stores, so that is another possibility. I seem to recall a mix of dry ice and alcohol made a good cooling bath, but I'm not certain that is right.

Another trick is to pulse the current, say one second on and several seconds off to prevent heat buildup in the wires or phosphor.