precisionworks

Flashaholic

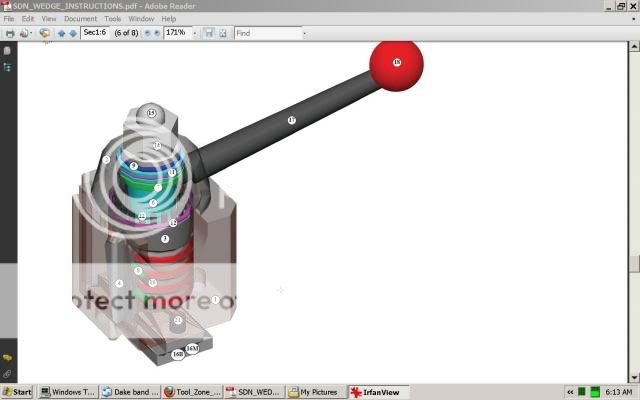

The brown truck left this today ... the toolpost came with a blank T-nut so that was the first item to machine:

I crept up on the size & ended up with a light tap in fit. The T-nut is threaded in the middle & includes a pair of reamed dowel holes.

The new square shoulder end mill was used to take off excess material. 1000 rpm, .250 DOC, pretty fast hand cranked feed.

The bottom of the SQCTP has matching dowel pin holes if someone needs those.

Internal threading tool & insert

60 degree stand up insert

Overall view of double ended holder

The two square shank holders

Blade style cut off-parting tool (gtn2)

And a boring bar & right hand tool holder

The nicest tool post I've ever seen + four blocks + five indexable tools :twothumbs

I crept up on the size & ended up with a light tap in fit. The T-nut is threaded in the middle & includes a pair of reamed dowel holes.

The new square shoulder end mill was used to take off excess material. 1000 rpm, .250 DOC, pretty fast hand cranked feed.

The bottom of the SQCTP has matching dowel pin holes if someone needs those.

Internal threading tool & insert

60 degree stand up insert

Overall view of double ended holder

The two square shank holders

Blade style cut off-parting tool (gtn2)

And a boring bar & right hand tool holder

The nicest tool post I've ever seen + four blocks + five indexable tools :twothumbs

This means I will have to sell my new DTM 65/AXA that I just got.

This means I will have to sell my new DTM 65/AXA that I just got.  Too bad cause I was really looking foward to using it.

Too bad cause I was really looking foward to using it.