Hi guys,

I coined the name piston drive and I think I'll provide a little background on how it came about.

Surefire came out with a really useful switch that is still in play on some of their lights. It's a tail cap switch that basically initially completes the battery circuit with a resistor in series and then on further depression completes the circuit without that resistor dropping the voltage powered to the head. In effect, you have two levels, first low and then high.

A number of us on CPF proceeded to use this simple and effective means of getting two speeds out of a flashlight. I designed a tail cap switch module I named the McE2S which was adaptable to the SureFire E series LOTC switch and provided for 2 speed activation of some of the SF LED heads as well as most of the E-series compatable heads others were building including the Aleph series of heads Wayne Y and I were involved in.

At some point, I was informed that SureFire has a patent on their 2 level tail switch and it would be wise for me to cease building these. I would state that the mechanics of how my module functioned is significantly different in design and I don't know if it actually infringes on the actual design of SF's switch but certainly the net result is the same and I admit that the idea of using a resistor to accomplish the 2 speeds came from SF.

I figured I needed to move the switch action away from the tail cap to avoid conflict. I also figured that if possible it would be nice to have a two speed light that provided two levels of constant current to the LED and no efficiency loss, as resulting from a resistor in series. I came up with the idea of two contact points in the head that would give you two circuits in play driving the LED. Wayne Y designed a number of converters that functioned with this mechanical design goal. We came to think of these as "x2" converters and they sport an initial contact named the Kilroy spring and then a second contact through a "C" shaped ring that surrounds the perimeter about Kilroy. The design of this battery can and exterior cover involved here reminded me of the piston and sleeve assembly in some of the ICE air cooled engines like the VW and Porsche. The terms piston and sleeve were adapted because you have to name the parts something for sake of identification and piston and sleeve made sense to me. :shrug:

There were and are a number of advantages to this design as well as compromises that would not be considered advantageous to some. The actual contact points where the circuits are activated or deactivated are exposed and easy to view when the head is removed for battery change or simple inspection. There was a reduction in number of components as well as seals in this design compared to a design where you have a battery tube and separate tail cap switch; clickie or LOTC.

Since the inception of the PD lights I designed and offered up, there have been some other manufacturers to use this design in their lights.

I concede that there are other lights including some SF lights that were present before my PD design that activate with the circuit making and breaking forward of the battery and at the head.

In a simple tubular flashlight design, there are only so many reasonable and ultimately self revealing means of activation and switching. It isn't rocket science and the granting of any IP may be more a case who was there first than any real breakthrough in innovation or novel design concepts. From one point of reference, perhaps Mag can be granted the modern flashlight IP and even SF considered a "follower".

To my way of thinking, the PD system was not borrowed from previous art. It came to be in order to accomplish battery connections to the converter located in the head of the light and avoid the tail switch means of activation as well as inefficiencies inherent in accomplishing a low level via resistance in the power line and "choking" or dropping the converter out of regulation.

Justin Case is correct in his comments regarding the SF lights that predated my PD. I was aware of them but they did not figure into my design thoughts what so ever because they involve proprietary batteries which bring both anode and cathode forward to the head as an integral element. In my design, the piston in conjunction with the replaceable and separate battery accomplish the same result but I didn't come about this design thinking in such lines. The Streamlite Strion or at least one I picked up a number of years ago did follow in the same form as these SF lights and if you are inclined to call the SF lights a piston drive then this Strion would be included I would think.

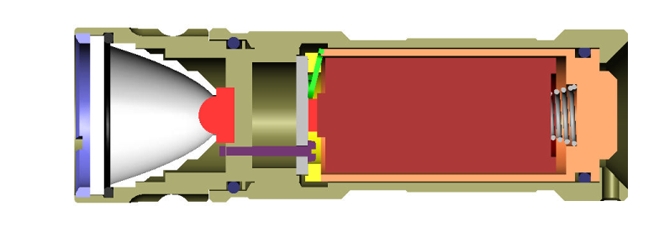

The image below shows a cut away cross section of my PD design which may or may not help shed some light on what at least I consider a Piston drive to consist of:

The light orange represents the "piston" and its contact with the green Kilroy accomplishes low output and then further forward, it contacts the yellow contact ring as well putting you in high or the second mode. I have since the original PD design used the same piston and sleeve for activation of two separate converters with their independent LED arrays which is the basis of my LunaSol design.

Hopefully this post sheds some light on what the Piston drive is about. As to why some people like it, I leave that to others...

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum