ti-force

Flashlight Enthusiast

First of all I'd like to say thanks to CPF member Got Lumens? for lending me his S12 for testing. Now for my results:

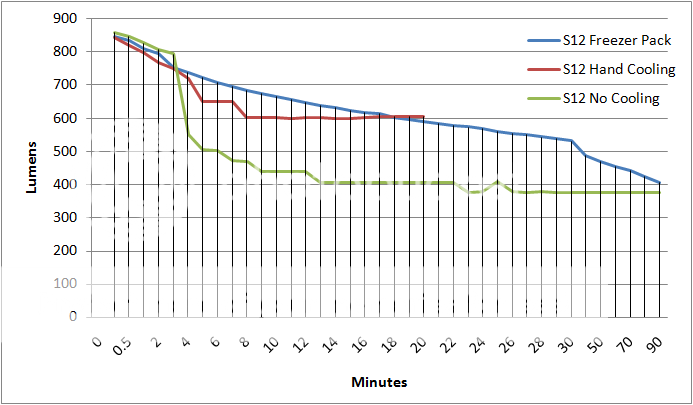

This light has thermal protection, which keeps it from being damaged by too much heat. I wanted to test this light in the same manner that most users will actually use this light, but I also wanted to test it with additional cooling methods, just for giggles..... So I used a freezer pack as one method, and my hand for heat sinking as another method, and also without any additional cooling at all, which means holding the light by the tailcap and letting the thermal protection do its job.

Obviously the freezer pack method gets warmer the longer the test is in progress, so this is not exact or controlled by any means. Also, I'm not certain if anyone actually lives in an environment that could keep this light as cold as my freezer pack for this amount of time, so please take this as it is. Also, when testing with my hand as an additional heat sink, I didn't see any need to run the light any longer than 20 minutes because the light had already stabilized, plus I wasn't doing a runtime test. Obviously the runtime will vary like the output at different temperatures, but I don't have time to do those tests. Here are my results:

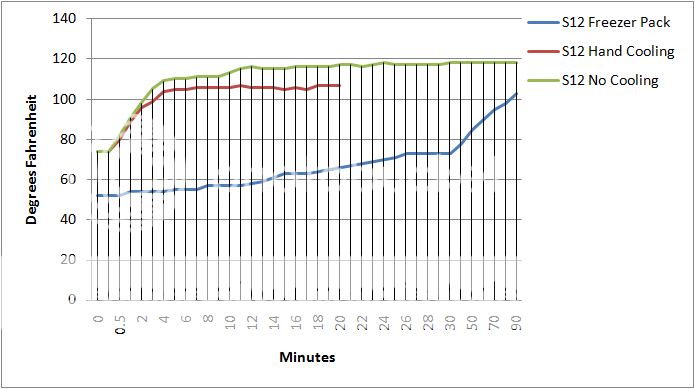

I also documented the temperature throughout all three above tests. I used an infrared thermometer to record degrees fahrenheit, and while I'm aware of the fact that infrared thermometers have some degree of error, especially if you're trying to take readings from a surface that's reflective (not the S12), I feel like it works well enough for what we need to know.

Here are my results:

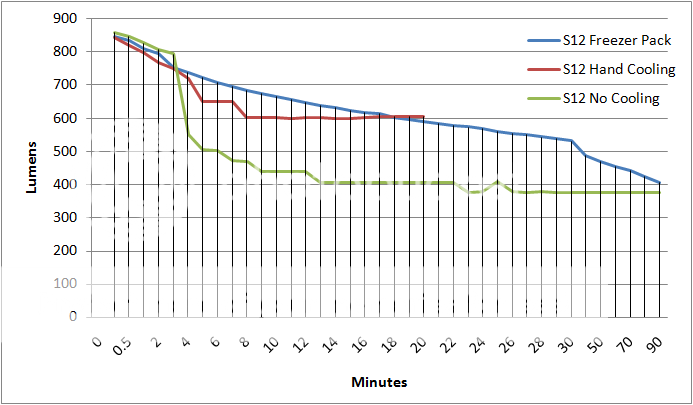

This light has thermal protection, which keeps it from being damaged by too much heat. I wanted to test this light in the same manner that most users will actually use this light, but I also wanted to test it with additional cooling methods, just for giggles..... So I used a freezer pack as one method, and my hand for heat sinking as another method, and also without any additional cooling at all, which means holding the light by the tailcap and letting the thermal protection do its job.

Obviously the freezer pack method gets warmer the longer the test is in progress, so this is not exact or controlled by any means. Also, I'm not certain if anyone actually lives in an environment that could keep this light as cold as my freezer pack for this amount of time, so please take this as it is. Also, when testing with my hand as an additional heat sink, I didn't see any need to run the light any longer than 20 minutes because the light had already stabilized, plus I wasn't doing a runtime test. Obviously the runtime will vary like the output at different temperatures, but I don't have time to do those tests. Here are my results:

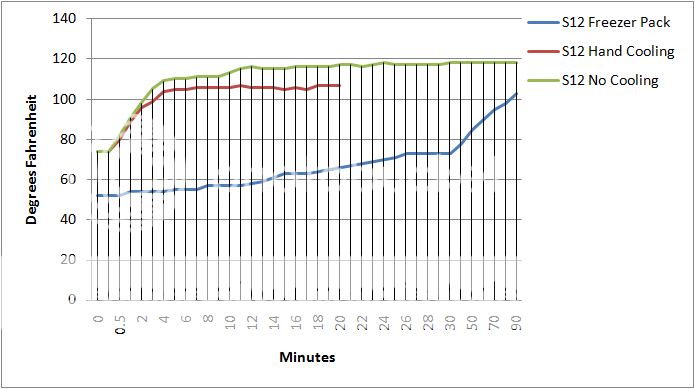

I also documented the temperature throughout all three above tests. I used an infrared thermometer to record degrees fahrenheit, and while I'm aware of the fact that infrared thermometers have some degree of error, especially if you're trying to take readings from a surface that's reflective (not the S12), I feel like it works well enough for what we need to know.

Here are my results:

Last edited:

:thanks:.

:thanks:.