The web page shows that you can pot these things as long as the potting compound is not conductive. I just wanted to make sure that these will not get too hot. Thermal potting compounds DO conduct heat, but not that well. Have you tried potting these yet? I just don't want to buy one and have it overheat. Thanks.

My general comments on potting and heatsinking of ANY of these new high current drivers (we're talking >2A here). I'm just choosing your email question to start off my discussion below:

The potting reference in the H6CC tech section is to the top of the board - for water proofing etc. I'll have to clarify that on my website.

It is the user's responsibility to calculate the heat dissipation in the driver - since you now have some efficiency curves to base your calculation on. You need to determine the watts be dissipated in your system and determine if the level of heat being generated in the driver and LED can be handled.

Just potting it into a brick and letting sit in a housing will obviously not be able to dissipate enough heat. That would be no better than using thermal epoxy to mount the driver to a small heatsink. e.g. if the driver is dissipating 2W, then whatever it is mounted on has to be able to dissipate that 2W AND maintain a stable temperature.

As you can imagine, I can't recommend whether potting would work or not - way too many variables including what kind of potting material, what shape you make the 'brick' (distance from the surface of the potting edge to the various devices on the H6CC board) and then how is the 'brick' mounted to the body of the light. What current you've set the output to? How many LEDs? What battery source? etc etc....

In summary, I HIGHLY recommend that you use the thermal pad (which I supply) or thermal adhesive tape to attach the bottom of the H6CC driver to your heatsink. That's the specific reason the H6CC was designed with components only on the top surface. This same scheme was used with the hipcc/hipflex/hyperboost and hyperbuck drivers (all high power drivers) very successfully.

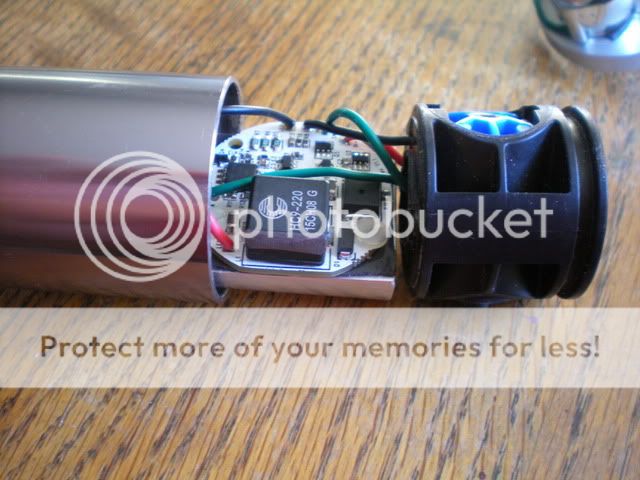

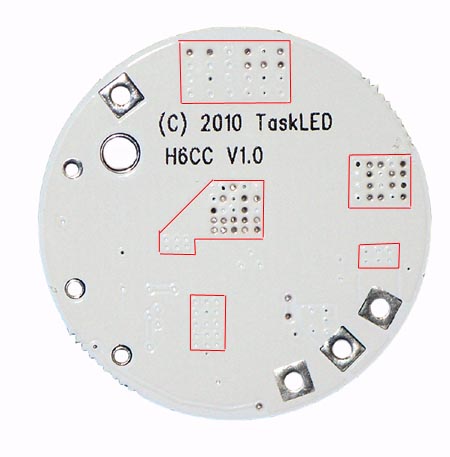

Designing a high power driver that does not deal with how to cool the devices is only providing 1/2 the solution to the customer. All the high power drivers I've designed since the maxflex have had to address the thermal path. Most of the new high power IC's, FETs etc utilize the PCB to remove heat - the switcher controller on the H6CC has a thermal pad UNDER the IC (same as per maxflex) that you can't see after the part has been soldered down to the PCB. Same with the FETs on H6CC. There are multiple vias under the switcher IC and FETs (and inductor and power resistors) to transfer heat from these devices to the bottom side of the PCB. You can see some of those thermal areas in this picture:

and it is those thermal areas that need the thermal pad to heatsink interface to transfer the heat from the devices.

With folk wanting drivers that can handle 30W to close to 100W you will have many watts being dissipated in the drivers - the cooling of the drivers is as important as the cooling effort being placed on the LED heatsink design.

Simple calculation here of a rather 'stressful' light). Assume you have 6.7A going to your 3 x SST-50/90's. That means 6.7 x 3.5 x 3 = 70W going to the LEDs. Assume you're powering this from 14.4V. From the efficiency curves in this thread, you have around 92% efficiency in the driver which is pretty decent. You will still have 70W x 8% = 5.6W being dissipated in the driver that needs to be removed from the driver. Potting the driver is not going to work.

Anyhow, in summary... I know a lot of folk (just read some of the somewhat recent SST50/90 threads) are all excited to get a driver for these new LEDs so they can build the meanest light out there... Great, but it's not quite the same as taking an XP-G and a 3W driver and making a pill for an xyz donor body. Even a single SST-50 driven at 5A is around 20W of system 'heat' that needs to be managed efficiently or you've just tossed a bunch of $$$ into the fire pit. That management requires attention to the LED heatsink AND attention to how the driver is going to be mounted to a heatsink AND the thermal paths from the heatsink to the body of the light.

Take care of the heat dissipation issues and the lights we build will work great and for more than a couple of minutes...

cheers,

george.